Thinkerbell Labs’ Annie is the world’s first Braille self-learning device that helps users learn to read, write, and type in Braille.

At the age of three in 1812, Louis Braille lost his eyesight after an accident while playing in his father’s leather workshop. When he was 10 years old, he was awarded a scholarship to attend the first Institute for Blind Children (Institution des Enfants-aveugles) and left his family and small village behind to further pursue his education in Paris.

At school, Braille was intrigued when he discovered night writing—a raised-dot alphabet created by an officer in Napoleon’s army and used to communicate without words or light on the battlefield. When Braille was 13, he began innovating his own version of it, reducing the complexity from a 12-dot system to a six-dot cell that is now the standard today.

For the blind and visually impaired, Braille literacy is a critical component for future success. Positive educational outcomes and employment hinge on this core knowledge. However, access to learning Braille can be incredibly challenging and requires a tremendous investment in time and resources both for educators and students. With a new innovative device, Thinkerbell Labs is on a mission to transform how Braille is learned by making it easy, accessible, and, yes, even fun.

Innovating for education inclusivity and accessibility

The inspiration for Thinkerbell Labs first started when the co-founders worked on a college project to build a Braille alphabet song box with Raspberry Pi. With overwhelmingly positive feedback from the visually impaired community, they started to learn Braille themselves and realized the opportunity to create a device that could transform Braille education.

Their flagship innovation, Annie, is the world’s first Braille self-learning device that helps users learn to read, write, and type in Braille on their own. Named in honor of Helen Keller’s teacher Anne Sullivan, it offers interactive and audio-guided lessons that allow students to independently learn, practice, and be assessed on Braille literacy.

Initially launched in India and with an investment from the popular TV show Shark Tank India, Annie gained global recognition. The company quickly grew, thanks to partnerships with organizations including American Printing House for the Blind (APH) in the U.S. for the distribution of the Polly version of the device and HumanWare in the UK. International collaborations have expanded Annie’s reach to countries like Australia, Ireland, and beyond.

Annie provides a tactile learning experience with real-time audio feedback that helps children build Braille literacy in an engaging and self-paced manner. The device speaks in a friendly voice, and students note that she even sounds like a friend.

“The content on Annie is available in 14 localized languages,” says Sana Dhawan, Marketing Associate, Thinkerbell Labs. “With Annie in schools, students can independently learn Braille without constant hand holding from educators, reducing the learning time significantly. It’s also a fun and gamified way to teach Braille with the combination of lessons, games, and vocabulary-building activities.”

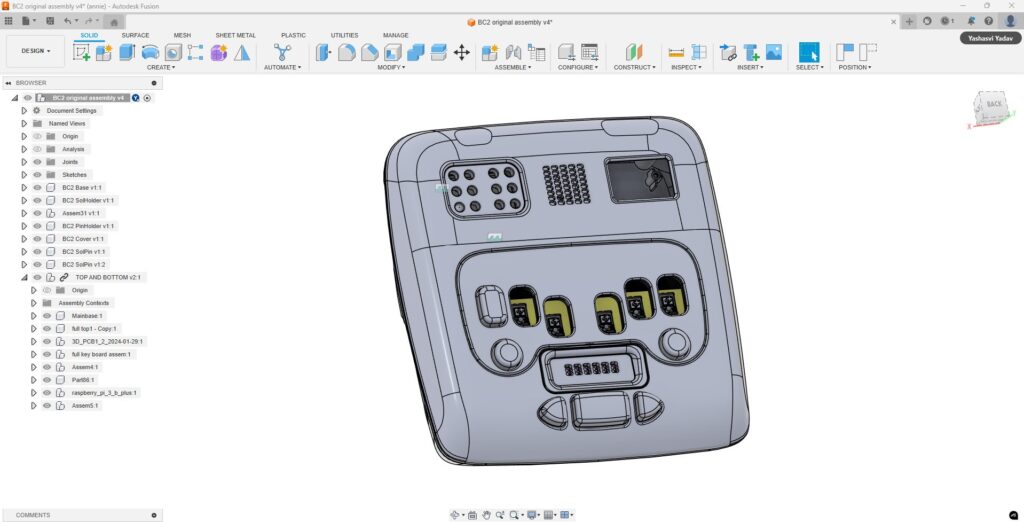

Innovating the next generation of Annie with Autodesk Fusion

The next version of Annie is currently in development to address user feedback and incorporate even more features. The team is using Autodesk Fusion for advanced modeling tools to create more ergonomic and user-friendly designs and taking advantage of global collaboration in the cloud for partners in the U.S., UK, and other regions to review and contribute in real time.

By adopting Fusion, Thinkerbell Labs can focus on enhancing the user experience, such as improving the tactile feedback in Annie’s Braille display. Based on this user feedback, the team adjusted vibration intensity. They also reduced operational noise by 70% to enable better learning. Fusion allowed them to rapidly prototype and implement these changes quickly and efficiently.

Gupta also moved to Fusion Electronics for their electrical designs. Annie contains hundreds of components. In addition to the precision of selecting and placing components, frequently updated libraries available in Fusion transformed his process. “It was very easy for me to make the shift,” he says. “I’ve reduced the time I spend on designs by 50%.”

“There are many small benefits that deliver big benefits as well,” adds Yashasvi Yadav Mechanical Design Engineer, Thinkerbell Labs. “Things like the ability to have multiple tabs open, autosave, or even auto-generating gears and other components through community-developed Python scripts have drastically reduced my manual design effort. With Fusion, about 50% of my overall design time has been reduced. My productivity has also increased because I don’t need to think about any other stuff while designing. I can be in the zone and just design.”

“I used to use SolidWorks, but I shifted to Fusion very early on because of its accessibility. With most of the computing done in the cloud, it’s easier for many people to access the software. You can share your designs without having to send files. Fusion is powerful software with a very friendly user interface. Anyone who’s new to designing can get their imagination out with CAD—and that’s a very good thing.”

—Yashasvi Yadav, Mechanical Design Engineer, Thinkerbell Labs

Streamlining operations to deliver Annie and Polly to more hands

To scale and streamline operations, meet growing demand, and keep affordability of the device first and foremost, Thinkerbell Labs turned to Fusion Operations. “Before Fusion Operations, our production data was scattered across multiple spreadsheets,” says Sai Sachit Pathak, Head of Business Operations, Thinkerbell Labs. “Tracking inventory, sourcing raw materials, and managing production was cumbersome and time-consuming.”

After evaluating different options, the team had a one-month trial and decided to move forward with Fusion Operations. “The Autodesk customer success team did a wonderful job getting us familiar with the technology and really helped us take a look at the operational blueprint of how to improve our manufacturing of Annie and Polly,” Pathak says.

Fusion Operations has now transformed their manufacturing and supply chain processes. Centralized data, real-time inventory tracking, and automated alerts via Slack deliver unseen levels of accuracy and efficiency. Access to data is available across the organization in real time. Fusion Operations has also brought new opportunities to efficiently scale production with the new demand for both Annie and Polly.

“Today, generating an inventory report with Fusion Operations now takes us five minutes instead of a week,” Pathak says. “We’ve also automated alerts for production issues, enabling faster problem resolution. This shift to Fusion Operations allows us to meet critical deadlines, such as fulfilling a recent contract for 2,100 Polly units.”

“For anyone looking to scale up their manufacturing processes, Fusion Operations is a perfect fit. It checks all the boxes that we want to tick. My advice is very simple: You don’t need to reinvent the wheel. It’s already been invented with Fusion Operations.”

—Sai Sachit Pathak, Head of Business Operations, Thinkerbell Labs

Making a difference—one device at a time

For the Thinkerbell Labs team, working on Annie and Polly is more than just a job—it’s a mission to make education inclusive worldwide.

“It’s an incredible journey working with the company, and it doesn’t feel like work,” Gupta says. “It feels like we’re truly helping someone when we see kids and even adults learning how to read and write in Braille. It’s an amazing feeling that you get to see the product that you have designed and made is making a difference in the world.”