& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

3 min read

How often have you been asked to “think out-of-the-box” on a specific design problem? All too often, we find ourselves limited by our training, “rules of thumb,” heuristics, past design history, our own biases, corporate rules, or the most dangerous phrase in business: “We have always done it this way.” At times, we cannot get out of our own way.

To date, two strategies for new design ideas and “thinking out-of-the-box” have been simulation-driven design and Topology Optimization. Much has been written about simulation-driven design and Topology Optimization as “Best Practices” for product development that leverages simulation tools early. Today, simulation is so fast that the result is returned in less than one minute. Coupled with Topology Optimization, algorithms automatically adjust the topology based on the input conditions and the results. The upshot is a reduction in physical prototypes, resulting in greater product performance as well as time and cost savings.

Five years ago, I would have agreed that these were the right paths to take, but over the last several years, a better, more logical “Best Practice” has emerged that embodies the term “thinking-out-of-the-box”: generative design.

To be clear, generative design is a capability accessed on the Autodesk Fusion 360 platform, a cloud-based CAD/CAM tool for collaborative product development that combines industrial design, mechanical engineering, simulation, electronics design, topology optimization, generative design, documentation, additive manufacturing, and CNC machine tool programming into one software solution. Fusion 360 can be purchased separately at an affordable price or is accessible as an entitlement to every licensed Autodesk PDMC user.

The biggest reason is that Simulation-driven design with topology optimization is hampered from the get-go is because it starts with human bias—a human-designed model. As a result, one may end up taking a pre-determined path, unknowingly optimizing a less than optimal design concept. Even the best and brightest engineers are only capable of developing, then exploring a few design concepts in the time allowed during a typical project.

Simulation-driven Design and Topology Optimization both require a completed design model before analysis can be started. That means that simulation and optimization are dependent upon the design process path a human has taken. Unfortunately, a human only has enough time and bandwidth to explore one or two design options before finally sending off to simulation (optimization).

In many companies, simulation is only allowed to be performed by a separate group of FEA experts. Simulation by these FEA Experts often becomes a gate in the process. This step adds time and cost to the process and in many cases may take the designer/engineer off the chosen design path. Therefore, in some cases, Designers and Engineers at times try to work-around this gate, even avoiding this step whenever possible.

Generative design software in Fusion 360 is built around artificial intelligence and machine learning. Algorithms automatically create the required geometry based on the performance, materials, conditions input, manufacturing process, and results, going much further than topology optimization’s ability to only adjust the submitted CAD model. Generative design in Fusion 360 begins with the definition of the engineering and design problem—not part history, or a human’s CAD model.

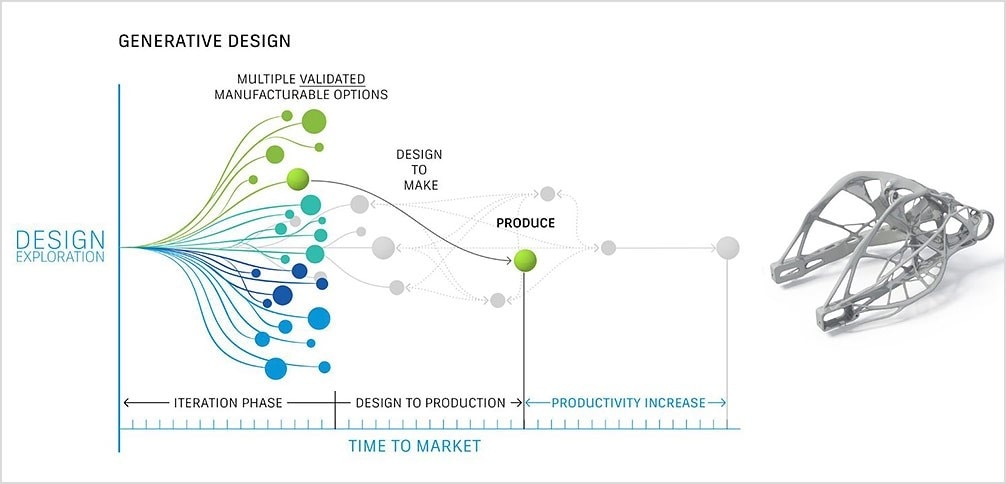

In contrast to current product development methods, generative design provides multiple upfront manufacturing-aware solutions, helping you get to market faster.

Generative Design in Fusion 360 lets the computer think out-of-the-box for you, taking training, corporate and human biases out of the mix. Generative design tools put decision-making back where it belongs—in the hands of the engineer and designer. The designer or engineer is the most knowledgeable on the performance goals, the required design parameters, and the loading and constraints the product will be subjected to.

The Generative Design process optimizes your designs by helping with part consolidation, reducing development time, and meeting cost constraints, among many others. It becomes a co-creation partner, solving complex mechanical engineering problems faster and without human bias, developing multiple design iterations for evaluation by the designer/engineer.

Generative design in Fusion 360 provides an opportunity to rethink the initial design concept and potential manufacturing methods. It provides an opportunity to explore hundreds of possible design concepts—through both traditional (subtractive) and newer (additive) manufacturing methods like 3d printing—as well as costing based on geometric complexity, materials, and manufacturing methods.

Generative Design is higher performing, easier to manufacture, and generates less expensive designs in less time—and the world has taken notice. Try Fusion 360 with generative design today.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.