In the world of Computer-Aided Design (CAD), there are two primary methodologies used for designing models: Top-down and bottom-up. Let’s explore top-down modeling vs. bottom-up modeling and how Autodesk Fusion offers the flexibility to utilize a hybrid approach, based on our Fusion – 15 Tips & Tricks ebook.

What is bottom-up modeling?

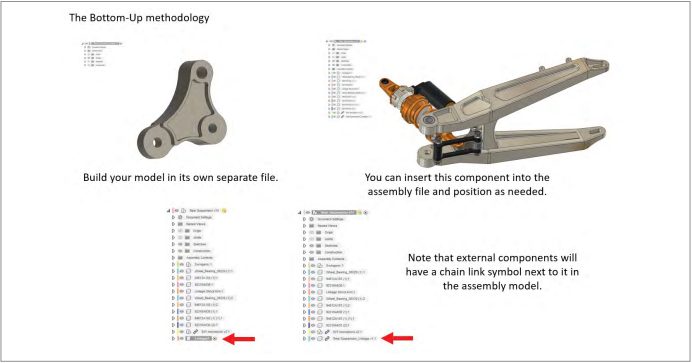

Bottom-up modeling is a traditional approach to design, where each component of the model is created independently in its own separate file. The designer then assembles these individual components into a larger assembly using a separate assembly file. In Fusion, these individual components are referred to as ‘external components.’

Advantages of bottom-up modeling

The bottom-up methodology offers several benefits, including:

- You can reuse individual components in other projects, promoting design efficiency and consistency

- You can manage each part independently, simplifying updates and modifications without affecting the entire assembly. This approach is particularly useful when working on complex designs with numerous interrelated components.

What is top-down modeling?

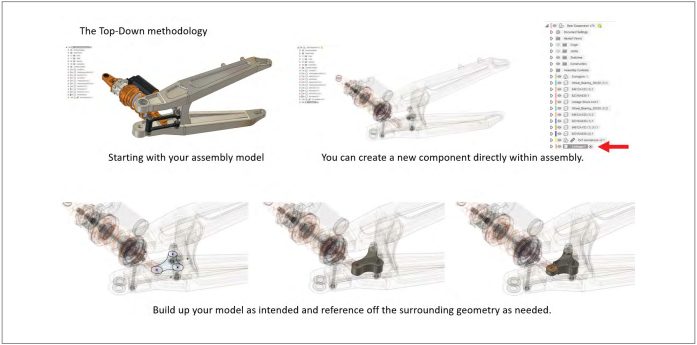

On the other hand, top-down modeling involves designing new components within the same file as the assembly. Fusion refers to these components as ‘internal components.’ With this approach, designers can create new parts directly around the existing assembly components.

Top-down modeling advantages

Top-down modeling offers rapid design iterations and quicker prototyping. Designers can build new components while considering the rest of the assembly, ensuring proper fit and alignment with the existing parts. This method is especially valuable during the conceptual phase, where creative exploration and fast modifications are crucial.

Combining both approaches

Fusion provides a powerful environment that allows designers to adopt a hybrid approach, leveraging the advantages of both top-down and bottom-up methodologies. This flexibility is beneficial for various design scenarios and ensures the best outcome for the specific project requirements.

Achieving efficient design workflows

To achieve efficient design workflows in Fusion, it is essential to understand when and how to use each methodology. Bottom-up modeling is ideal for creating standard components that can be reused across multiple projects. On the other hand, top-down modeling shines when speed and adaptability are critical, especially during initial design stages.

The role of external components

In bottom-up modeling, external components play a vital role. These are the individual parts designed separately and later combined in an assembly. Fusion allows easy management and updates to these components, making design iterations smoother and faster.

The role of internal components

Conversely, internal components in top-down modeling are designed within the assembly file itself. This approach promotes seamless collaboration between components and encourages innovative design solutions.

Choosing between top-down and bottom-up modeling largely depends on the project requirements and design objectives. Both methodologies have their strengths, and it is crucial to evaluate the specific needs of the project to make an informed decision.

Exploring design methodologies in Fusion

For a more in-depth understanding of top-down modeling vs. bottom-up modeling in Fusion, check out this informative video:

In conclusion, understanding top-down modeling vs. bottom-up modeling is vital for those working with Fusion. Each methodology offers distinct advantages, and by combining both approaches, you can achieve efficient and innovative design workflows that suit your specific project needs.