Image Source: Wikipedia

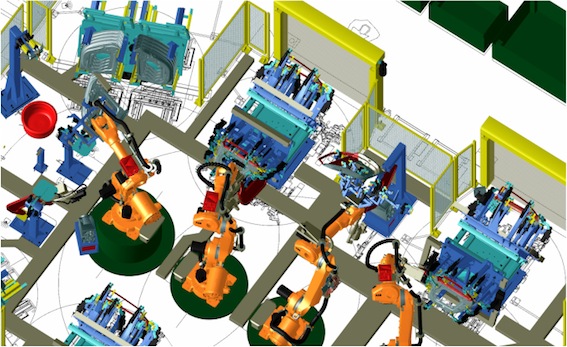

The concept of a digital twin in manufacturing is one that has grown out of increasing connectivity. It’s a concept that allows manufacturers to monitor a product’s performance in real time using a digital model that responds identically to the real world product. As Industry 4.0 continues to drive forward the manufacturing sector, we see an increasing need for digital twin design.

Transpiring from the idea of a digital twin comes the idea of Product Line Engineering (PLE). This process is where the twin is born. At its roots, it is an engineering process that takes specific products across a line of products and allows for communication in-between. To understand this better, we need to apply it to a real-world example, like automotive manufacturing.

When you apply PLE to creating a line of cars, you can imagine that there are different engineering teams working on the different models of the car. One for the base model, one for the mid-range, one for the luxury model. While the teams may be working on the same product, their design goals are often different and their specific designs often diverge in key areas. This means that since they are all working on the same product, just a different area of the line, communication between teams becomes crucial to accomplishing the overall design goal. This may seem simple with only 3 teams, but it gets more and more complicated as different versions of a product are created.

With Produce line Engineering, all of the components of a product line are fed into a management software that creates a portfolio for each product. This helps in preventing redundant design flows between teams, like designing the same user interface twice on a car’s infotainment system. It also helps when problems arise with final models by allowing us to see the scope of a flaw.

From this management of the product line through the overarching framework of PLE, we arrive at the conclusion that a digital twin of a product is necessary. A physical product is imagined that uses IoT and cloud data to inform its digital twin of what is occurring. Creating a digital twin is becoming more and more of a common practice in manufacturing, but PLE planning is a necessary step in the creation process. It allows us as engineers to understand whether design failures apply to a certain model, or whether one configuration can perform a certain task.

Think of it this way: Product Line Engineering collects the engineering data needed and establishes a framework of engineering models demonstrating how they are connected. From this framework, we can develop digital twins of certain products to better understand how they will and do perform in the real world. The PLE framework is the DNA of a digital twin.

Integrating PLE management into our growing digital manufacturing infrastructure is becoming a more common practice. The growing availability of useful product data necessitates that we give some forethought to how we can evaluate that data when it is supplied to us. PLE and digital twins allow us to receive real-world feedback and understand how to apply that feedback to the redesign or improvement process.

This post was originally posted to Short Sleeve and Tie Club. You can read the original here.