Fasteners are an integral part of modern engineering and product design. Autodesk Fusion offers a suite of tools and features that support fastener engineering throughout the whole lifecycle.

When we look at skyscrapers, intricate machinery, or cutting-edge aerospace technology, we often overlook the tiny yet crucial elements that hold it all together—fasteners. These seemingly inconspicuous components are the backbone of structural integrity and functionality for our entire world.

With such an important role to play in our world, fastener engineering is a crucial yet overlooked part of the product design process. In this article, we’ll explore the intricacies of fastener engineering and discover how Autodesk Fusion is revolutionizing this essential field.

A look at fastener engineering

Fastener engineering is a specialized field that focuses on the design, manufacturing, and application of fasteners—devices that mechanically connect two or more components. The discipline encompasses a broad spectrum of activities, including material selection, load analysis, manufacturing processes, and quality control.

Material science

A comprehensive understanding of materials science is essential for selecting materials that can withstand specific stresses and environmental conditions. For instance, a fastener used in a high-temperature application may require a different material than one used in a corrosive environment.

Mechanical load analysis

Engineers must calculate various types of loads, such as tensile, shear, and torsional forces, to ensure the fastener can handle the stresses it will encounter. This analysis is crucial not only for the initial design but also for material selection. For example, a fastener expected to bear high tensile loads would need to be made of a material with high tensile strength.

Manufacturing processes

Fastener engineers must be well-versed in manufacturing processes like forging, machining, and heat treatment to translate the design into a physical product. They need to work closely with manufacturing teams to ensure that the production process adheres to the design specifications and tolerances. Any deviation could compromise the fastener’s performance and, by extension, the integrity of the entire assembly.

Quality control

Quality control is the last, but certainly not least, important step in the fastener engineering process. Engineers must establish rigorous testing protocols to ensure that the manufactured fasteners meet or exceed industry standards. Only after passing these stringent quality checks do the fasteners become ready for their intended applications.

How Fusion supports fastener engineering

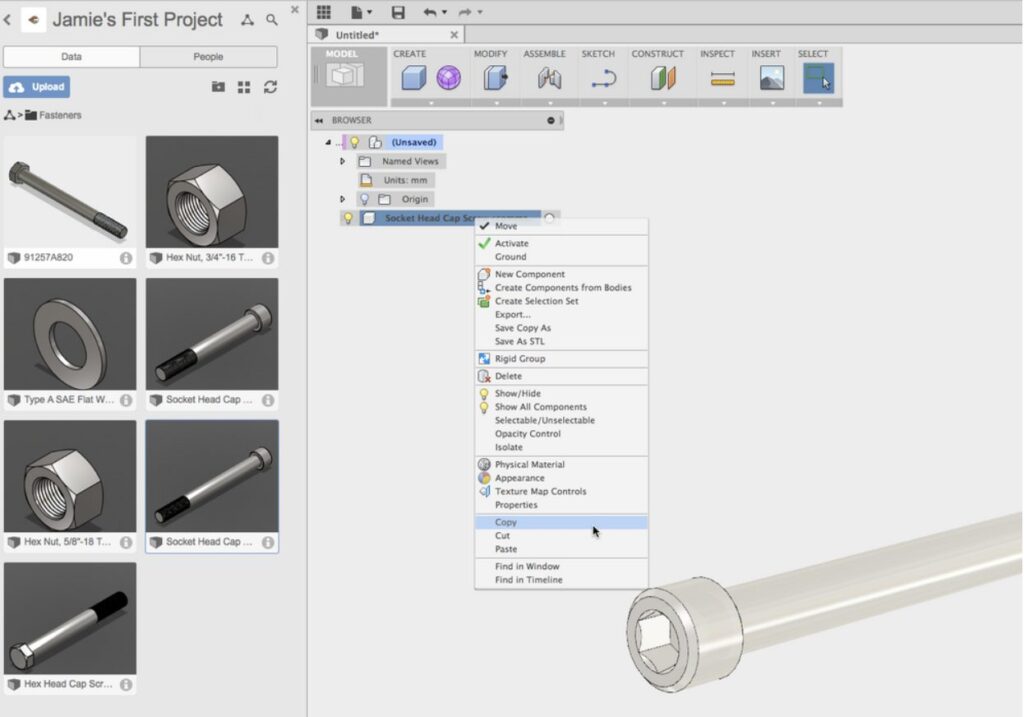

Fusion supports the field of fastener engineering by offering robust design and simulation tools. With parametric design and simulation features, Fusion allows engineers to create custom fasteners that meet any project’s specific requirements.

To support material selection, Fusion offers a comprehensive material library that allows engineers to analyze and select materials based on their mechanical properties. This feature streamlines the material selection process and ensures that engineers choose materials that are fit for purpose.

Fusion also aids in the manufacturing process. The software offers toolpath generation and production line setup features, which facilitate a smooth transition from design to manufacturing. This ensures that the fasteners are not only well-designed but also efficiently produced.

Finally, Fusion facilitates quality control with features for simulating fasteners as well as setting up quality control protocols. These features ensure the final product meets industry standards and specifications, reducing the risk of real-world failure.

Empowering engineers

Fastener engineering is a multifaceted discipline that plays a pivotal role in the success of various engineering projects. Fusion amplifies engineers’ capabilities by offering tools that cover every aspect of fastener design, from concept to final product. By leveraging Fusion, engineers can ensure the production of high-quality, reliable fasteners that meet the rigorous demands of today’s industries.