This post is also available in: Deutsch (German)

This blog post delves into the different additive manufacturing processes and technologies to help you find the right one for your workflow.

If you’re reading this, you probably already know what a 3D printer is (if you don’t, then read this article about 3D printing vs. injection molding). But do you understand the differences between the vast number of additive manufacturing processes, technologies, and their applications?

To start, here are three easy ways to categorize the various additive manufacturing technologies:

1. Melted Solids

There’s a whole band of additive manufacturing technologies that rely on melting a material down and extrude it out of a nozzle or end effector of some kind. These additive technologies essentially reconstitute a “complete” material (like from a spool) into a new shape by melting and layering into a new form.

2. Solidifying Liquids

You probably didn’t see this coming, but yes, there is a process of additive manufacturing technology that is the total inverse of melting solids. Relying typically on photosensitive resins or polymers, these 3D printers will usually work by applying a laser or a projection to solidify a thin film of the resin into a solid object.

3. Fusing Powders

Possibly the most widely known technology format, powder fusion works exactly as the name suggests. The material you’re working with is a powder in its “raw” format and fuses together either through a binding agent or by melting the material with a heat source.

Having dealt with a handful of the different ways you can additively manufacture things, let’s dive into the specific additive manufacturing processes.

Additive Manufacturing Processes

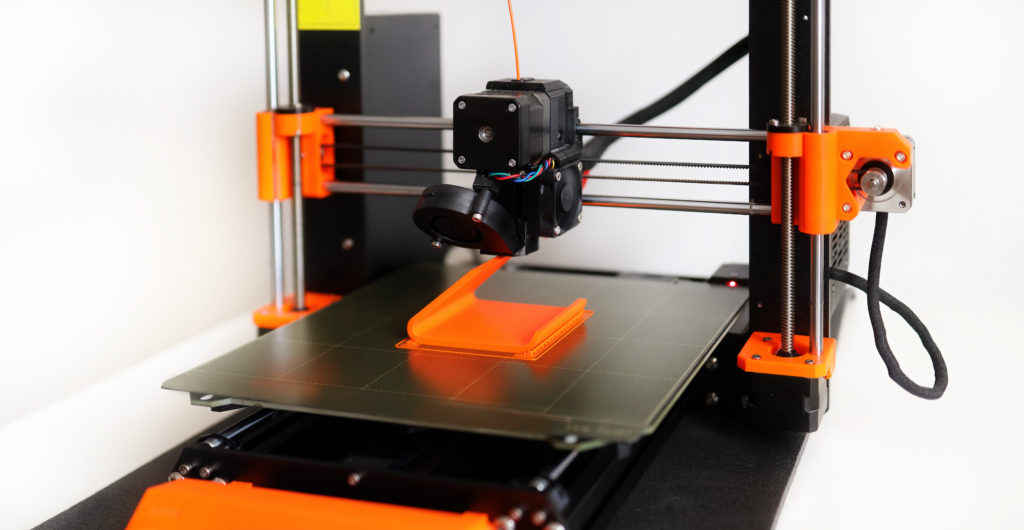

FFF: Fused Filament Fabrication

Chances are, when someone says 3D printing, you think of this additive technology. Easily the most prolific additive technology from the boom in desktop machines that started around 2010, FFF machines manufacture products with a spool of plastic that is driven through a hot end extruder that melts the plastic to liquid form, which is then laid out in a pattern that is one slice of the object. You may be aware of FFF thanks to additive manufacturing hardware companies like Ultimaker.

FFF Applications

FFF is a fantastic workhorse additive manufacturing technology for prototyping, making basic products, testing ideas rapidly, and general ideation workflows. Of course, FFF can also be used with more “permanence” in mind to manufacture products too. FFF is a reliable technology for additive manufacturing, with few things that can go wrong, minimal downtime, and generally well-produced objects. It’s limited mostly by the resolution of printing, which will create a trade-off on accuracy for speed. FFF parts also require some post-processing for finishing, and the ridgelines usually need to be removed for painting.

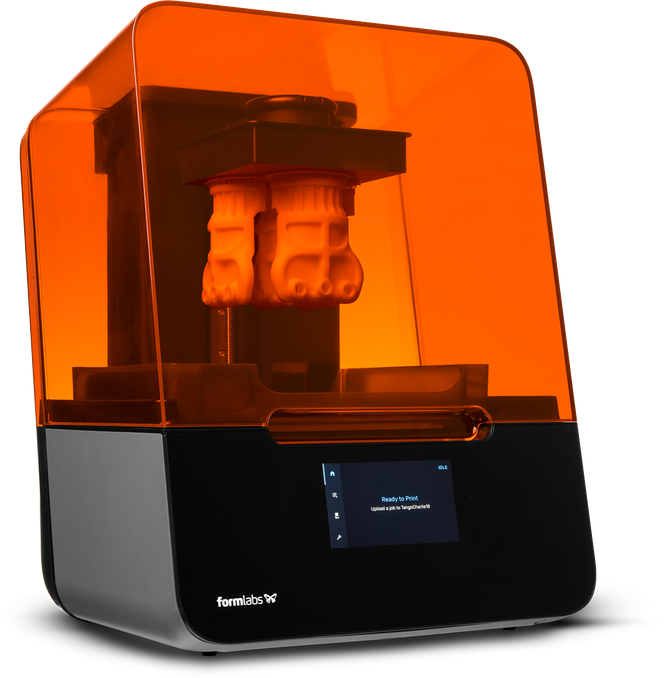

SLA & DLP – Stereolithography & Digital Light Processing

Arguably the second most popular/famous 3D printing process after FFF, this additive technology also benefitted from a boom in companies starting around 2010. These 3D printers use a photosensitive tank of resin, with the object being made by passing a laser over the layer to solidify the resin in place. DLP differs from SLA by projecting the entire image layer using a projector instead of a laser. Arguably DLP is faster, as the entire layer is projected at once instead of using a laser to trace, but there are again trade-offs, typically around the surface finish. You are most likely aware of SLA printing through companies like FormLabs.

SLA & DLP Applications

There are a lot of resin options available, most of which simulate a plastic’s material properties. SLA benefits over FFF are typically accuracy and surface finish, so if you’re printing objects with lots of fine small details, SLA will serve you better. However, the SLA process demands more of you as an end-user, requiring extra steps after the printing is done for the part to be ready. SLA can also print big parts and is used at scale. You may recall seeing the Adidas Futurecraft 4D shoes with a 3D printed sole, which were achieved with SLA-based tech from Carbon.

MJF – Multi Jet Fusion

Whoa, jet fusion? And there are multiples of them? Yes. This additive technology is as amazing as its name suggests. Multi Jet Fusion produces nylon parts using an inkjet system not too dissimilar to what you would have in a regular paper printer. The head of a multi-jet fusion machine is considerably more complex than a regular printer head, sending material and binding agents. MJF tends to give a much more consistent finish and material property than its Selective Laser Sintering counterparts.

MJF Applications

For professionals, this process adds color and materiality together so that prototyping can get a lot closer to the final object than with other prototyping processes. This additive manufacturing application is particularly convenient when color matters, not just from a finishing perspective but also for visual representations such as printing a heat map of stresses directly onto the part, making it easier to understand what’s going on when reviewing your object.

DMLS – Direct Metal Laser Sintering

Before we dive into this one, it’s worth noting that DMLS is a relatively new additive manufacturing process relative to other laser sintering processes. Most likely, you will know what SLS (Selective Laser Sintering) is and the nylon parts it makes. DMLS works by using the same process, using a laser to fuse metal powder. Typically used to prototype complex parts and manufacturing mass customized products, DMLS enables you to manufacture parts that will be much stronger (because, well… metal is stronger than plastic for the most part) and test.

DMLS Applications

Relative to other processes, DMLS is expensive, as it is a metal additive manufacturing process. This is expected given the materials, the technology, and the required safety protocols to house a DMLS machine are costly. But the cost is, of course, worth it to be able to test and validate processes. If you work in aerospace or automotive, a DMLS printer will be one of the most effective ways to prototype complex, unique parts and be as close to the finished part as possible. You might be thinking, “what about machining?” Of course, you can still use machining as part of any prototyping process, but we’re here to discuss objects that would necessitate the use of additive manufacturing.

DED – Direct Energy Deposition

DED printing is best thought of as the metal counterpart to FFF for plastics. DED machines will use either a powder or a wire (not too dissimilar to a plastic spool) to heat the metal at the extrusion point and depositing it with a nozzle.

DED Applications

From the description of DED, you may think it would be used in similar applications to FFF, but with metal parts. In reality, DED’s most common use today is building off existing parts and being included in a hybrid manufacturing process for high-end additive manufacturing applications. One of the most famous examples would be the use of hybrid manufacturing in the Port of Rotterdam. They will 3D print parts onto damaged rudders to make a replacement part and then use a machining process to bring the part to a completed state, ready for use on a new ship.

Of course, the options listed above are not the only additive manufacturing technologies that can be used to make products, but all of these are available in Autodesk Fusion or Netfabb as outputs for your workflow.

What additive process do you use and what for? Tell us in the comments section. And if you’re ready to take your additive manufacturing to the next level, here’s how Fusion can help.