Unlock the power of automation in Fusion 360 CAM with these techniques to help improve productivity when machining your next part.

Are you ready to enhance your Fusion 360 CAM workflow and unlock the power of automation? In this article, we’ll explore actionable tips to streamline your programming process, save time, and make your CAM programming experience more efficient.

By mastering these techniques, you’ll not only optimize your productivity but you’ll also enjoy a smoother programming journey within the Fusion 360 CAM workspace.

Utilize toolpath templates for quick setup and rapid quoting

When programming in Fusion 360, take advantage of toolpath templates to accelerate your programming workflow. Instead of creating toolpaths from scratch for every new part, save your preferred set of toolpaths as templates. By doing so, you can quickly call them up whenever you start a new setup, saving you valuable time and effort.

Take it further by creating templates tailored to different machining variations following these steps:

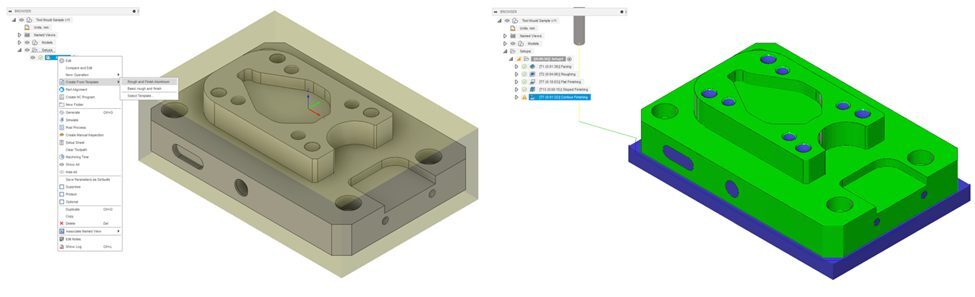

- To create a template, highlight all of the toolpaths that you wish to add to a template.

- Right click and select ‘Store as Template’ and give your template a name.

- Now, to bring in this template, first create a setup.

- Right click on it and select ‘Create from Template’, then choose the template you wish to add.

Templates can give you an 80%+ head on start on machining jobs, especially if you use the same type of toolpaths and setting regularly.

Common examples include templates for various material types or specific categories of parts you frequently work with. This approach not only provides a head start when programming new parts but also allows you to share your expertise with colleagues and teammates, fostering collaboration.

PRO TIP: Combine templates with ‘Machining Time‘ estimation to create a rapid quoting system for new incoming parts, streamline your quoting process, and improve overall efficiency.

Automate calculations with formulas in toolpath value fields

Did you know that you can automate calculations within Fusion 360 CAM? The toolpath settings offer a multitude of fields that enable precise control over various aspects of your toolpath operations. What’s even better is that these value fields support formulas, allowing you to automate calculations and further streamline your programming.

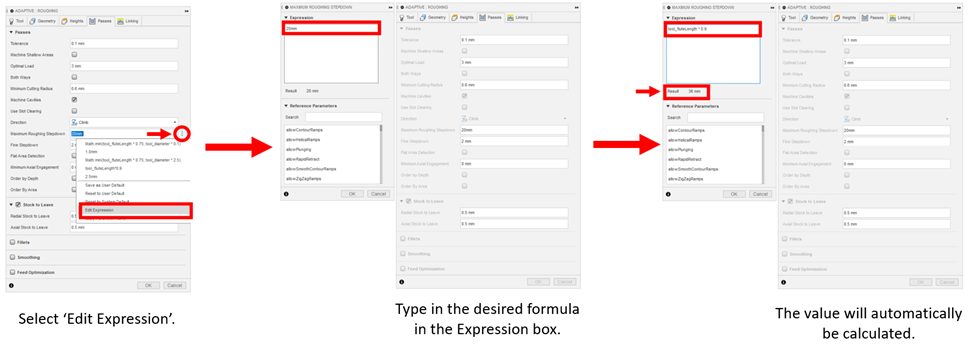

Rather than manually entering values, you can incorporate formulas by selecting the three vertical dots next to the field and choosing ‘Edit Expression’. Here, you can utilize pre-defined formulas or construct your own by leveraging the built-in library of parameters. These parameters include tool length, tool diameter, flute length, and more. The full list can be found here.

A common example is to set the ‘Maximum Roughing Stepdown’ field to be equal to the value of 90% of the tool flute length. Incorporating automation in your settings reduces the number of decisions you need to make and helps prevent errors.

Unlock the full potential of Fusion 360 CAM by embracing automation and utilizing toolpath templates and formulas. Streamline your workflow, improve collaboration, and enhance productivity. Start implementing these techniques today to experience a smoother and more enjoyable CAM programming journey.