No matter how you slice it, creating an optimized design takes ample planning and experimentation. It’s essential that products meet certain performance (and durability) requirements under specific operating conditions, and teams must also balance these goals with cosmetic standards. The design process has always been collaborative and iterative.

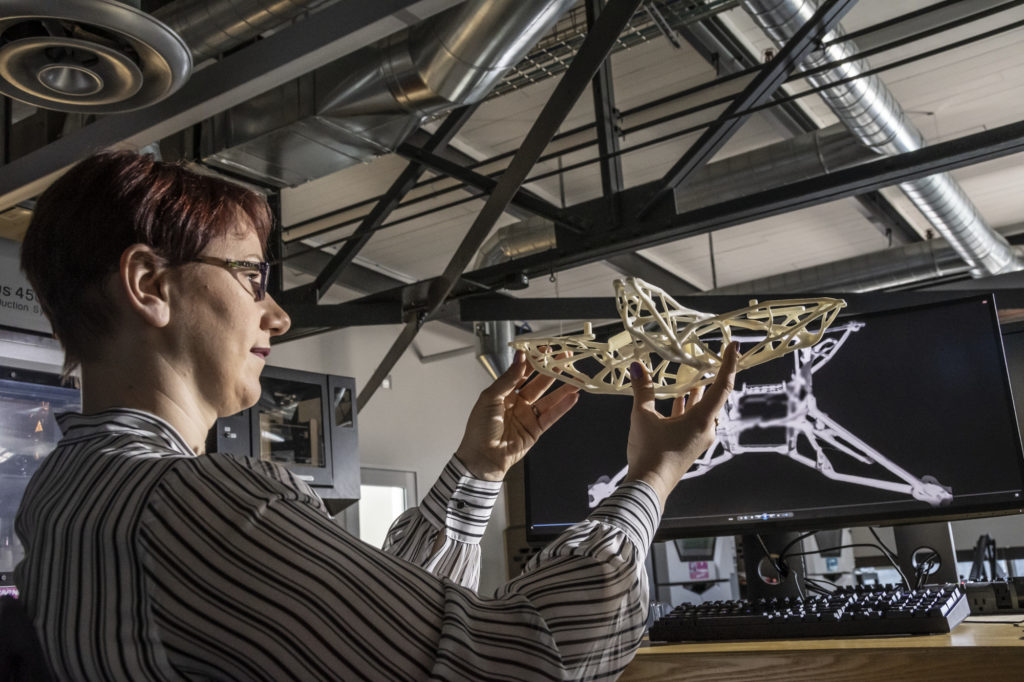

Generative design — the alternative to lengthy brainstorming sessions — helps automate and accelerate the prototyping process. As great as the traditional collaborative design process is, it can often become time-consuming and limiting. If you’re looking for a plethora of design options, the generative approach is a good look.

What is Generative Design?

Generative design is an explorative process, driven by your design goals. The software you use accepts these inputs — or design parameters — and generates many number of designs to satisfy them. Your design team will choose the best option from there. You can specify new parameters if those options don’t suit your project. But, what essential design factors come into play?

- Performance requirements

- Spatial specifications

- Materials

- Manufacturing methods

- Budget constraints

The sky’s the limit with generative design, as the platform is genuinely adaptive to your evolving needs. Going back to the drawing board is simple; it doesn’t involve hours of concept creation. We can offload challenging prototyping tasks to applications, which complete them in small fractions of the time. That keeps teams agile and helps products get to market faster.

Generative design has many applications in the following disciplines:

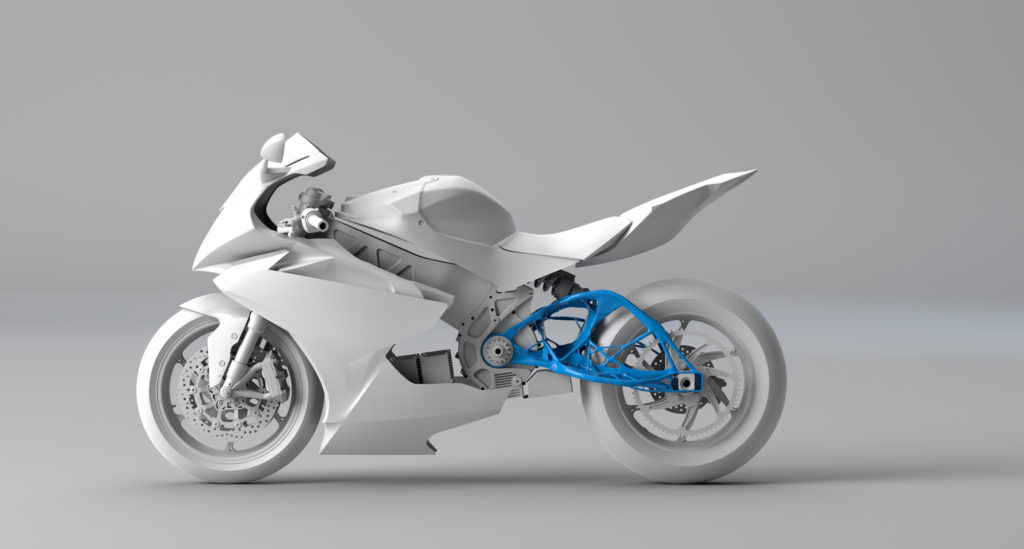

- Automotive

- Aerospace

- Architecture

- Building

- Construction

- Consumer goods

- Industrial machinery

- Manufacturing

Generative software doesn’t just create these variations; it also tests them for viability. These designs would have little value without practicality, making automated testing essential. Your program learns with every batch of models.

Exploring Further Generative Design Benefits

Automated design creation and testing aside, what does generative design offer? For one, testing extends beyond “yes or no” validation for each prototype. Your application will provide detailed data based on each design’s successes and failures. Teams can harness this information and tweak inputs accordingly. Fast-tracking optimization becomes that much easier — especially since team members can access the cloud-based data from anywhere.

Cost Savings

Getting things done quicker saves working hours, which, in turn, saves money. On a deeper level, each traditional prototype (physical or otherwise) costs money to create. Generating multiple options simultaneously saves money that one might otherwise pour into separate engineering or prototyping processes.

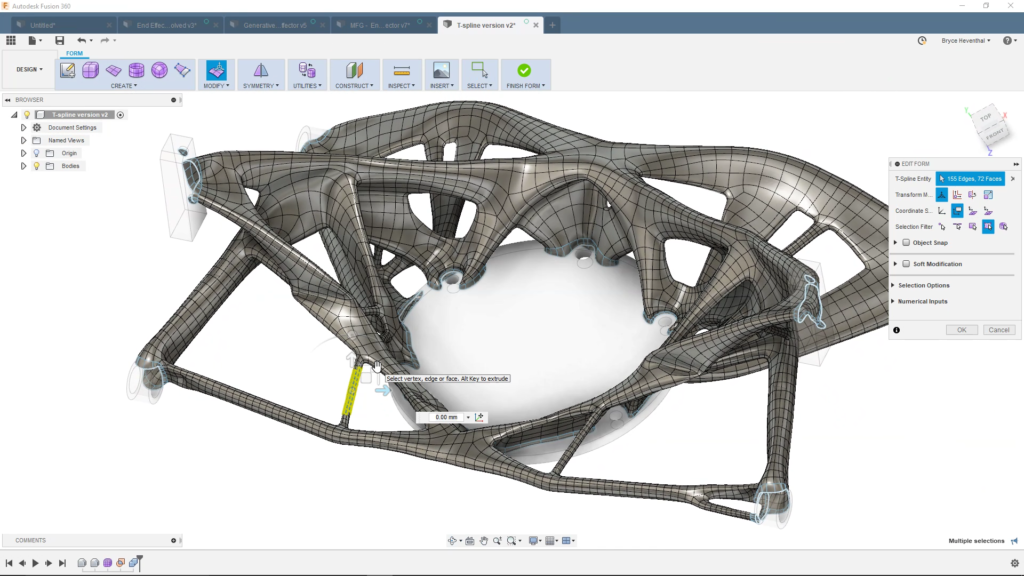

Consider those older solutions required specialized design software, which siloed conception from testing. Modern, generative software offers a unified experience. Forget obtaining expensive licenses or making unneeded purchases — popular software suites like Fusion 360 bundle everything together under a single platform.

Generative design in Fusion 360 will also help you select the most cost-effective designs. Great design incorporates both feasibility and scalability — material costs (and availability) play massive roles. For example, the unit cost for steel might be too costly. What if you could extract similar results with aluminum, and secure ample quantities from your supply chain? Making these changes can help your bottom line.

Redefining Which Designs are Possible

Intricate designs are complicated — sometimes too complicated for traditional methods. Today’s structures incorporate non-linear components, lattices, and shapes. Generative designs account for modern manufacturing, including additive manufacturing and subsets like 3D printing. Generative design in Fusion 360 can incorporate these complex geometries with little trouble, eliminating certain steps used when creating physical designs, like building molds or dies, and leading to more significant cost savings.

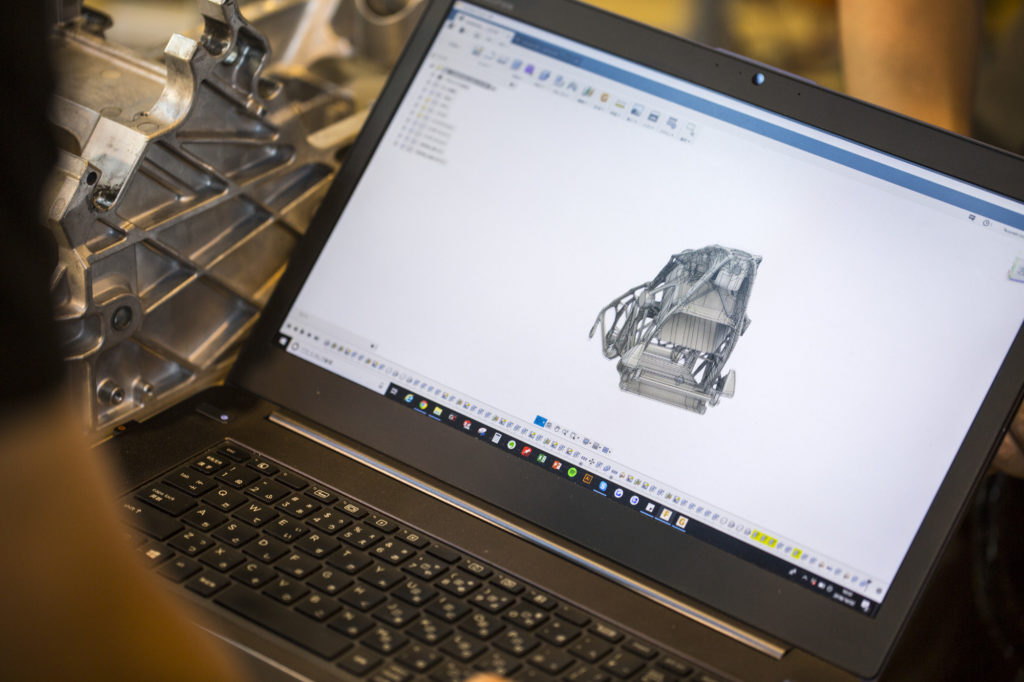

Generative Design in Fusion 360: The Answer to Remote Work

The cloud-based component of generative design in Fusion 360 is groundbreaking, especially when employees work from home. Now more than ever before, it’s easy to bring all team members in on the design process. Thanks to automation, teams can tackle other duties in tandem, and the design process doesn’t demand continual input. Generative design also covers numerous industries, and companies can harness these methods to jumpstart product development. Generative applications could churn out your next big design.

The digital-first working environment demands remote solutions — generative design is the answer.

Start using generative design in Fusion 360 Today.