Fusion 360 closely partners with Haas Automation to reduce the pain of getting set up with your Haas machine and Fusion 360. Take a look at the following tips to work smarter, not harder, and stay tuned for Pt. 2, where we’ll share some more tips!

As a machinist, there’s nothing more frustrating than trying to balance time between optimizing programs vs. getting the machine running. In an ideal world, you’d minimize every retract and trim every second of air cutting while also doing some fancy calculations on the benefits of an extra tool change for a dedicated tool.

No one wants to run an inefficient program or see a machine standing waiting for a program. So, let’s look at three tips for using Fusion 360 with your HAAS machine.

1. Reduce Feed Moves

Feed moves are a necessary evil in our world. As much as we hate to see our machine move slowly, they’re there to protect the tool—specifically when it comes into contact with the material or moves at a slower feed rate while near your component. There are a few tips and tricks inside Fusion 360 to help you reduce these slow feed motions.

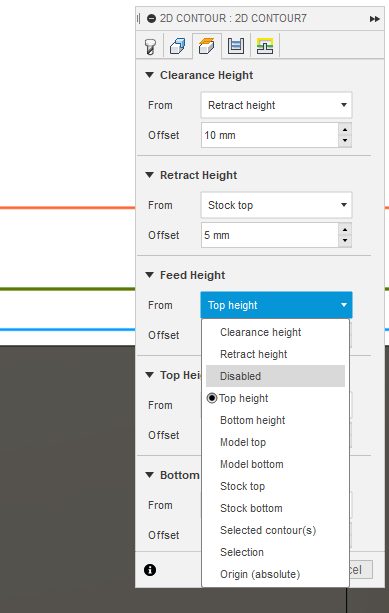

Take a 2D contour or chamfer toolpath, for example. The safe default behavior is to feed from the stock top plus a little extra for clearance. This is a safe way to machine. However, if the pocket you’re machining with the 2D contour is deep inside of your part, feeding all the way from the stock top can be a painful sight to watch.

Did you know you can disable the feed height? The machine will now move into the cut at the much higher lead in feed rate, rather than the slower plunge feed rate used by default. This is also a good trick for chamfering operations, helping reduce those cycle times.

2. Use G0 (Post Property)

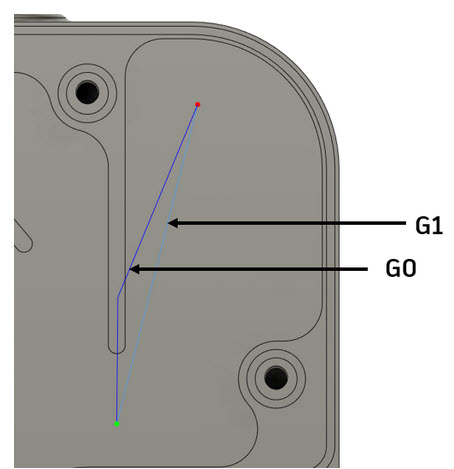

Let’s take a step back to when you first learned to run G-code. You probably remember manually writing your first program with G1s for the linear moves and G2s and G3s for the arcs. You also probably remember G0 being the rapid move. Go from X0 to X10 as fast as the machine can. You may have noticed that Fusion 360 does not use G0s by default. But why wouldn’t we use the most efficient way of moving the machine?

Well, G0s can have issues. With G0, you can have something called a “dogleg move.” I won’t go into full detail, but a dogleg move is where the machine finishes a move in one axis before another. This causes a nonlinear interpolation (see the diagram below). Although we start and end at the same place, the G1 toolpath takes a straight linear route. Whereas the G0 finishes the move in the y-axis before the x-axis. In this case, this causes a collision on our part.

Now we know the issues we have with G0 moves, but what are our options?

The default behavior from Fusion 360 with a HAAS machine is to output G1s where G0s would typically go. And then use a “high engagement feed rate,” which is a post property.

However, if you’d like to use G0s to reduce noncutting time on your machine, you can select the Use G0 post property. This will now use G0 moves to transition in and between toolpaths. This does run the risk of having those dogleg moves occur. However, there’s a setting on your HAAS control called Setting 335 Linear Rapid Mode. This will make G0s perform like a G1.

3. Master Machine Simulation

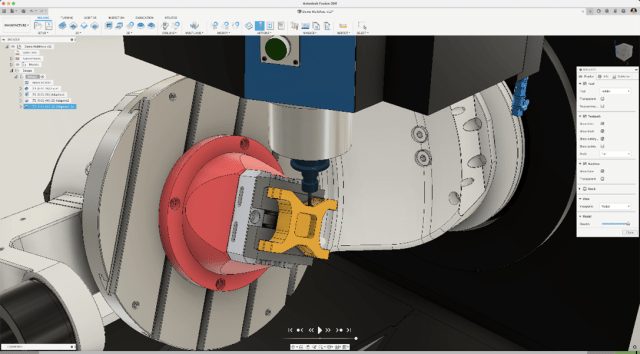

Fusion 360 has revolutionized how we think of the integration between CAD and CAM. One integrated solution gives the right tools to the right people. The ability to simply add fixtures and workholding to your CAM designs allows you to see the entire picture when programming. While also referencing heights from your workholding geometry.

Taking this one step further, we have machine simulation in Fusion 360 to use with your HAAS machine. We have a free-to-use comprehensive library of HAAS CNC machine tools. Downloading the machine model and selecting this in your setup will animate the machine movements while simulating the toolpath. With the library of HAAS machines being pre-configured and free to use, there’s no excuse not to simulate the machine’s movements for that extra layer of verification.

Ready to get started? Achieve faster integration for your Haas Automation CNC machine with Fusion 360.