This post is also available in: Italiano (Italian) Deutsch (German) 日本語 (Japanese)

Simulation software allows you to avoid costly rework by understanding how your 3D design will perform under real-life conditions prior to manufacturing. Read on to the benefits of simulation software and how Fusion 360 can help.

All design processes begin with some form of ideation. It’s next to impossible to create a final product without making the first draft. A writer wouldn’t publish a novel without first revising and rewriting their first draft several times. As such, The same is true with product design.

Designers and engineers must have the necessary tools to test their 3D designs to ensure they will perform under real-life conditions before manufacture.

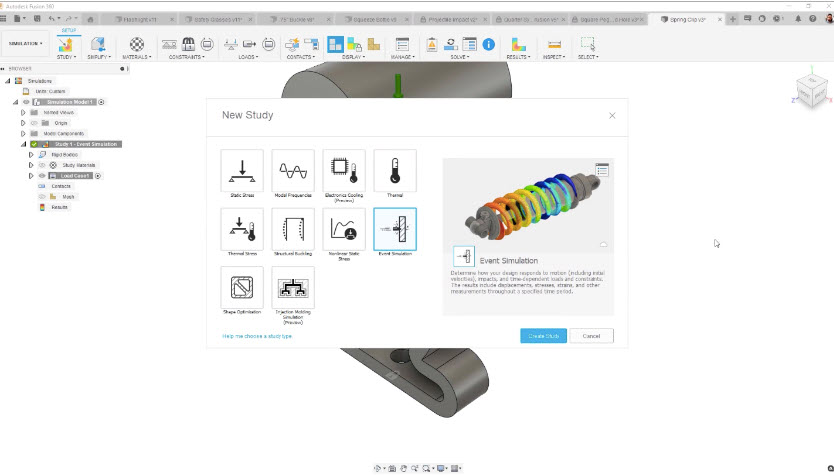

Fusion 360 has once again taken a step ahead of the competition by offering extended capabilities. The Fusion 360 Simulation Extension is a comprehensive collection of simulation study types to help you test 3D designs.

What is simulation software?

Simulation software is a digital testing ground for 3D designs prior to being manufactured. Different software packages vary, but they all offer pre-loaded testing environments for several different real-world situations. Take, for example, 3D printing. Using simulation software, you can test structural integrity, thermal tolerances, and injection molding manufacturability.

The benefits of simulation in the design process

There are several benefits to simulating tests for a design, including reducing costs, decreasing production times, and saving resources. Manufacturing a product that doesn’t work or breaks after a few uses isn’t good for any manufacturer. In short, it will lead to bad reviews, decreased sales, and a damaged brand reputation.

Simulations place the product into a real-world situation to test tolerances, functionality, and manufacturability — all of which are done virtually. Costly iterative design processes of the past included wasteful spending on manufacturing multiple physical prototypes, wasted time testing the physical products, and wasted resources after having no way to recycle minuscule prototypes.

The Fusion 360 Simulation Extension

Fusion 360 already boasts a professional, comprehensive, integrated cloud platform combining computer-aided design (CAD), computer-aided manufacturing (CAM), computer-aided electronics (CAE), and printed circuit board (PCB) under one umbrella. Further, on top of the base package, there are multiple extensions to choose from for various applications. One of which is the Fusion 360 Simulation Extension.

The Fusion 360 Simulation Extension contains simulation study types to help you test and investigate your 3D design before manufacturing the final product. The extension provides ways to test products under real-world conditions before leaving the simulated environment.

Just as one wouldn’t buy a car without testing it first, designers and engineers wouldn’t manufacture a product without adequately testing it. As a result, the best way to run a series of tests is within a virtual simulation.

Don’t let yourself get stuck in the ideation phase, wasting time, money, or resources creating an endless assortment of physical prototypes. Try the Fusion 360 Simulation Extension for your next project!