What is capacity planning? Why is it important? What strategies are there for successful capacity planning? Read on to find out.

When you’re running a production pipeline, you need to make sure that you’re operating at your maximum capacity. What does maximum capacity look like? When every employee assignment and task is delegated appropriately, and when the time spent on each part of the production process is optimized. Sounds nice, right?

When you’re operating at maximum capacity, your clients will receive products as quickly as possible, and your profits will remain steady. Similar to production scheduling, planning out your capacity will save you time and prevent a lot of headaches.

What is capacity planning?

Capacity planning is as simple as it sounds. When you have a team staffed with members working a certain number of hours, your maximum capacity is when they work their full hours and complete their delegated tasks within those hours. Say you have a team of 50 employees who each work roughly 40 hours a week. That means that your capacity is 2,000 hours per week.

Capacity planning means measuring your employee capacity to ensure that you’re operating as predicted. Let’s say that these 50 employees are working 40 hours a week, but their tasks only take half the amount of time to complete. This means that they’re operating at 50% capacity, which means there’s unnecessary downtime. Or, let’s say these 50 employees are working their full 40 hours, but their tasks take twice the amount of time predicted. Here, they’re at 200% capacity.

Both scenarios are problematic. Too much downtime means you’re paying too much and may need to downscale your operations. On the other hand, if your employees are at double capacity, you can cause serious morale problems and even lose overwhelmed personnel.

What’s the goal of capacity planning?

The main goal of capacity planning is to make sure you meet your requirements while maximizing your time and money. Capacity planning outlines exactly where your focus is being most delegated and how well your pipeline can handle both current and future demand.

What factors affect capacity planning?

The factors that determine your capacity can be concrete and straightforward to analyze. They include your plant’s specifications like its layout, the speed of machines, and its location. They can also be fairly hard to analyze, like the size of the team you have delegated to each task, how costs factor into their training and promotion, and even how you schedule them.

Your standard operating procedures may also factor into your capacity planning, as your SOP will determine your safety policies and procedures. Everything from your staffing, location, policies, and SOPs will determine how you create your capacity plan.

How to classify capacity planning

Capacity planning is classified based on how long implementation takes. You can choose to enact a long-term, medium-term, or short-term capacity plan.

Long-term capacity planning

Long-term capacity planning takes into account the various moving parts in your company where capacity will directly affect your output on a bigger scale. Things like the locations and design of your plants will factor heavily into your long-term capacity plan. For example, allocating duties for positions in your organization or even the maximum capacity of your individual machines/equipment will direct how you design a long-term capacity plan.

At its simplest, long-term capacity planning outlines how your pipeline will handle output and production in the long range. It takes into account the future demand your company will need to meet, hence the “long” in the long term.

Medium-term capacity planning

Medium-term capacity planning looks at a shorter time scale than long-term capacity planning — usually 3-18 months. They include more immediate decisions like hiring or outsourcing some of your operations temporarily to keep up with the demand that you predict will taper off.

Short-term capacity planning

Short-term capacity planning is the shortest time scale and is usually employed when an immediate fix to a problem in the pipeline is needed. For example, say your production tracking system flags a specific area of your piping that is bottlenecking. You can allocate staff to that area and perhaps increase overtime for your staff already assigned to that section of the company.

Short-term capacity planning is potentially the most costly, as it solves current problems but usually requires more resources and money. When a short-term capacity plan is enacted, you should take the medium and long-term ranges into consideration, or else the same problems clogging your pipeline can happen again.

How to measure employee capacity?

Employee capacity is typically measured when your financial resources are in flux; you can often measure if employees are over or under capacity by how much you are clocking in overtime, hiring more staff to keep up with demand, or reassigning staff when demand is low.

Ideally, you catch these issues early enough that they don’t influence your pipeline too much. An effective capacity plan will use forecasting and predictive analytics to determine whether the demand will be there and how many employees will be affected.

Capacity planning strategies

Capacity planning can also be determined by what kind of planning you will be doing in your company. They differ not only on a time scale but also in general type.

Match strategy

The match strategy is a plan that uses forecasting and monitoring of your demand in your industry to determine your strategy. This means directly tailoring your capacity to match industry demand. The pros of this strategy are that you have a pretty good idea of what the demand for your product will look like, and you can tweak the plan accordingly. The downside is that this strategy requires constant monitoring and incremental tweaks in line with industry shifts. Simply speaking, this is a low-risk, high-demand strategy.

Lag strategy

The lag strategy is the general opposite of the match strategy. It’s the most conservative of the capacity plans. Lag capacity plans usually wait until there is demand before tweaking capacity in the pipeline. This means that much of your hiring and allocation of resources will happen on the fly. This ensures your staffing costs will be low, but it can lead to delays if, say, demand suddenly increases unexpectedly.

Lead strategy

The lead strategy is the most radical. It involves enacting changes in anticipation of possible market demand. This strategy makes the most of predictions and forecasts as the crux of its plan. However, if the demand is lower than anticipated, your staffing costs could be sky-high compared to the output needed.

What is resource allocation?

Resource allocation is very similar to capacity planning, but it focuses more on employees and staffing directly. This type of allocation tracks employee hiring and compares it against project completion time and efficiency metrics. Properly allocating resources keeps employees happy since they won’t be overwhelmed. It also keeps you happy as your pipeline will benefit from their optimized workflow.

How can Fusion Operations help with capacity planning?

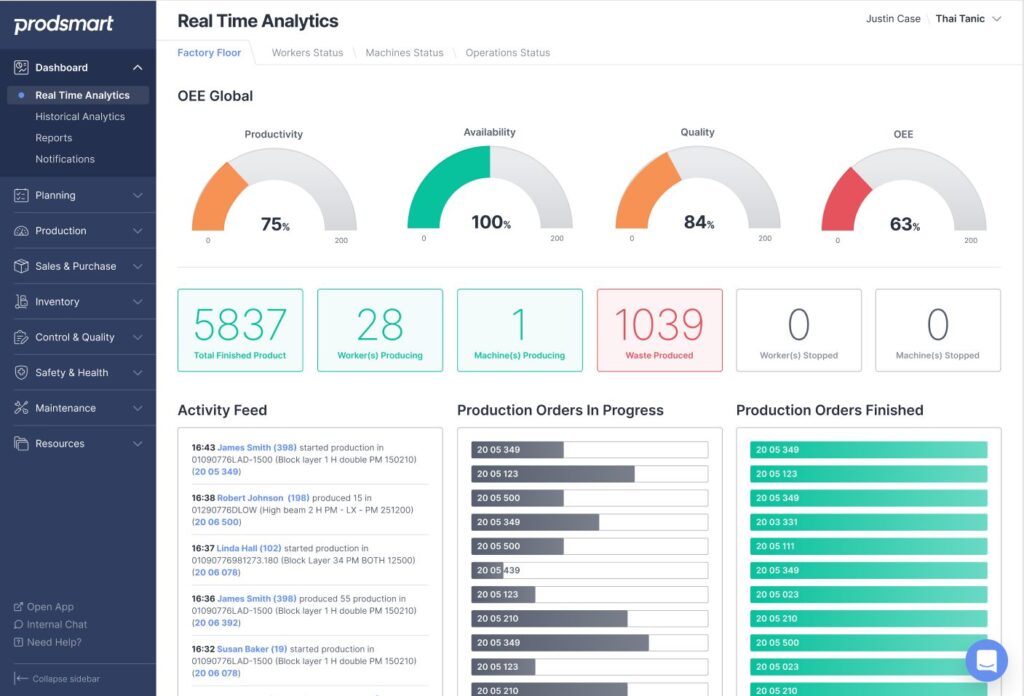

Fusion Operations is in the business of giving relevant, real-time information from the shop floor that can support decisions and optimize production processes. Our patented manufacturing execution system (MES) offers a flexible solution that is easy to use and tailored to your needs through paperless data collection and seamless integration.

Capacity planning is an essential part of running a business and keeping costs low. By keeping track of capacity, you will know beyond a shadow of a doubt where your money is being spent, how efficient your output is, and how you need to change to meet demand.

Ready to optimize your production pipeline? Let Fusion Operations lead the way.