Fused Deposition Modeling (FDM) is transforming additive manufacturing, and with Autodesk Fusion, you can seamlessly design, optimize, and prepare models for production in one powerful platform—enhancing precision and efficiency every step of the way.

Fused Deposition Modeling (FDM) is arguably the single most prominent technology in the field of additive manufacturing. FDM is a layer-by-layer process that creates three-dimensional objects from digital models, and has gained widespread adoption for its versatility, cost-effectiveness, and accessibility. This article explores the fundamentals of FDM, its applications across various industries, and how Autodesk Fusion enhances its implementation in product design workflows.

The technology behind FDM

FDM is a form of additive manufacturing that constructs objects by extruding thermoplastic materials layer by layer. The process begins with a virtual 3D model, which is sliced into thin layers using slicing software. The FDM machine then heats a thermoplastic filament and extrudes it through a nozzle onto a build platform, following the path defined by the digital model.

As compared to other forms of additive manufacturing, FDM’s advantage is its material diversity and speed. Thermoplastics like ABS, PLA, and PETG are common and relatively affordable. On the other hand, advanced materials, such as carbon-fiber-reinforced plastics and high-performance polymers, are used in high-performance engineering applications but have increased costs. The nature of the process supports rapid prototyping, functional testing, and even end-use part production.

A variety of industries—spanning aerospace, automotive, healthcare, and consumer goods—leverage FDM for its ability to create complex geometries, lightweight components, and customized designs. For example, FDM is used to produce jigs, fixtures, and molds in manufacturing settings, while in the medical field, it is utilized to create patient-specific surgical guides and prosthetics.

Despite its advantages, FDM has limitations. Challenges like anisotropy—where parts are weaker along the Z-axis—and surface finish quality require consideration during the design and post-processing stages. Addressing these issues often involves optimizing print settings and post-fabrication processes like sanding or vapor smoothing.

How Fusion enhances FDM applications

Autodesk Fusion is an integrated platform that streamlines the FDM workflow and makes it a powerful ally for designers and engineers. Its capabilities span from design conceptualization to production-ready output and supports the transitions between stages.

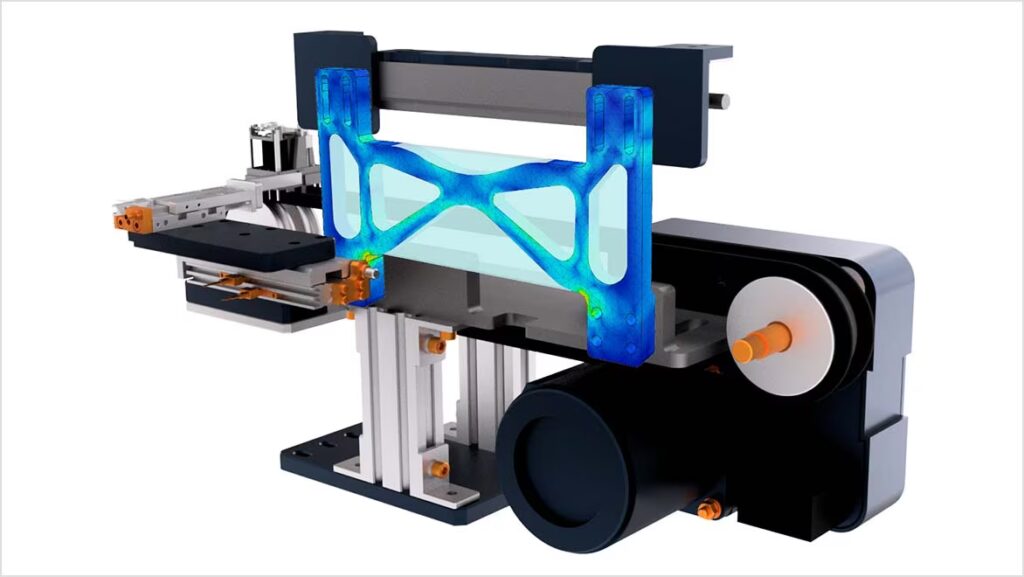

The software’s parametric and direct modeling tools allow users to create intricate designs that are optimized to FDM’s capabilities. Users can optimize part geometries to minimize material usage while maintaining structural integrity to effectively address cost and weight considerations. For example, Autodesk Fusion’s topology optimization features enable the generation of lightweight designs that are particularly well-suited for aerospace and automotive applications.

To ensure a successful printing process, Autodesk Fusion includes built-in tools for preparing 3D models for additive manufacturing. Its slicing capabilities allow for precise layer planning and support structure generation in complex geometries. The ability to visualize and simulate the printing process within the software minimizes errors and material waste, which reduces the need for costly trial and error.

Collaboration is another strength of Autodesk Fusion. Its cloud-based platform allows for real-time sharing and feedback on designs, making it easier for teams to work together on FDM projects. Whether refining a prototype or finalizing a production-ready part, Autodesk Fusion sees that every stage of the process is efficient and effective.

Empower additive manufacturing

FDM is an important technology in additive manufacturing that uniquely enables industries to produce complex, customized, and functional components with ease. To add, FDM’s applications continue to grow as advancements in materials and techniques develop. With tools like Autodesk Fusion, designers and engineers can fully harness the potential of FDM for designs that are optimized for both performance and manufacturability.