Explore mechatronics engineering, an interdisciplinary field combining mechanical, electrical, and control engineering to develop intelligent systems. Learn about its foundational concepts, applications across industries, and the role of Autodesk Fusion plays in facilitating the design and simulation of mechatronic systems.

Mechatronics engineering

Mechatronics engineering is an interdisciplinary field that merges mechanical, electrical, software, and control engineering to develop intelligent systems and products. As technology continues to evolve, the lines between these traditionally distinct engineering disciplines have blurred, giving rise to mechatronics.

The rise of mechatronics is integral in developing advanced systems that integrate mechanical components with sensors, actuators, and microcontrollers. Such systems often aim to enable machines to perform complex tasks autonomously or semi-autonomously.

Understanding mechatronics engineering requires exploring its foundational elements, applications, and the technology driving this convergence.

The foundation of mechatronics engineering

At its core, mechatronics engineering seeks to optimize the interaction between mechanical systems and electronic control systems.

The field emerged in response to the growing demand for machines that are more adaptable, efficient, and capable of performing tasks requiring high precision. For example, consider a modern automotive braking system. Unlike traditional mechanical brakes, a mechatronic braking system uses sensors to detect the speed and pressure applied by the driver, a microcontroller to process this information, and actuators to apply the brakes with optimal force. This integration results in a more responsive, safer, and reliable system.

Varied applications of mechatronics

Engineers apply mechatronics principles across various industries, from manufacturing and robotics to healthcare and consumer electronics.

In manufacturing, engineers employ mechatronic systems in automated production lines where robots perform tasks such as welding, assembling, and quality control with minimal human intervention. These systems combine mechanical design with sensors that monitor various parameters and software that controls the operation, leading to increased efficiency and precision.

In robotics, mechatronics aids in developing autonomous systems capable of navigating and performing tasks in dynamic environments. Drones, for example, rely on mechatronics for flight control, obstacle detection, and payload management. Their ability to autonomously perform complex maneuvers results from integrating mechanical design with advanced electronics and control algorithms.

The healthcare industry also benefits from mechatronics, particularly in developing medical devices such as prosthetics, surgical robots, and diagnostic machines. These devices often require precise control of mechanical components, which is achieved through sophisticated electronic control systems. For example, modern prosthetic limbs use sensors and microprocessors to detect the user’s muscle signals and control the limb’s movement, providing a more natural and responsive experience.

Autodesk Fusion and mechatronics engineering

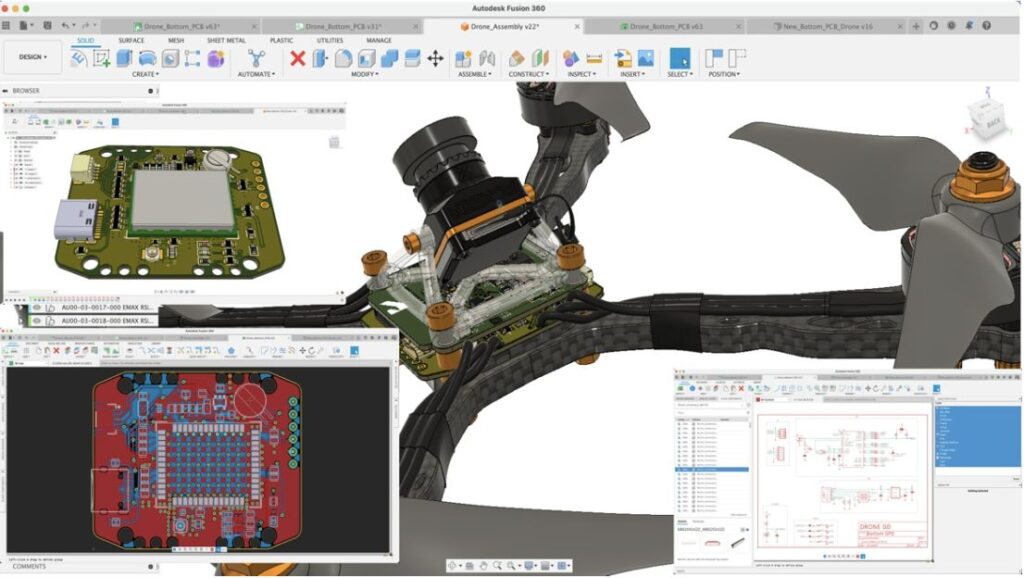

Software tools like Autodesk Fusion are essential in developing and refining mechatronic systems.

Autodesk Fusion offers an ideal platform for mechatronics, as it provides designers with an integrated platform where they can design, simulate, and test systems all in one place. The ability to seamlessly transition between mechanical design, electronics integration, and simulation within a single environment is very advantageous for mechatronics engineering.

In addition, Autodesk Fusion’s mechanical design tools allow engineers to develop detailed models of components and assemblies — which helps to optimize mechanical aspects of systems for performance and manufacturability. These models can then be combined with electronic components, such as sensors and actuators, to form a complete mechatronic system. The ability to design mechanical and electronic components within the same platform reduces the likelihood of design errors and ensures that all system parts work together seamlessly.

Furthermore, simulation is another fundamental aspect of mechatronics engineering. With Autodesk Fusion, engineers can simulate the behavior of both mechanical and electronic components under various conditions. This allows for the testing and iteration of designs before physical prototyping. By simulating these interactions, engineers can uncover potential issues early in the design process and make the necessary adjustments.

Finally, Autodesk Fusion’s collaboration features make it convenient for multidisciplinary teams to collaborate on mechatronic projects. Engineers from different disciplines can share their work, provide feedback, and collaborate in real-time, guaranteeing that the final product integrates mechanical, electronic, and software engineering.

The future of engineering

Mechatronics engineering will be a fundamental tenet of the future of intelligent systems design. By integrating mechanical systems with electronics and software, mechatronics enables the creation of more adaptable, efficient, and performant machines. As the field continues to evolve, tools like Autodesk Fusion will help engineers in designing, simulating, and bringing these advanced systems to life.