& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

4 min read

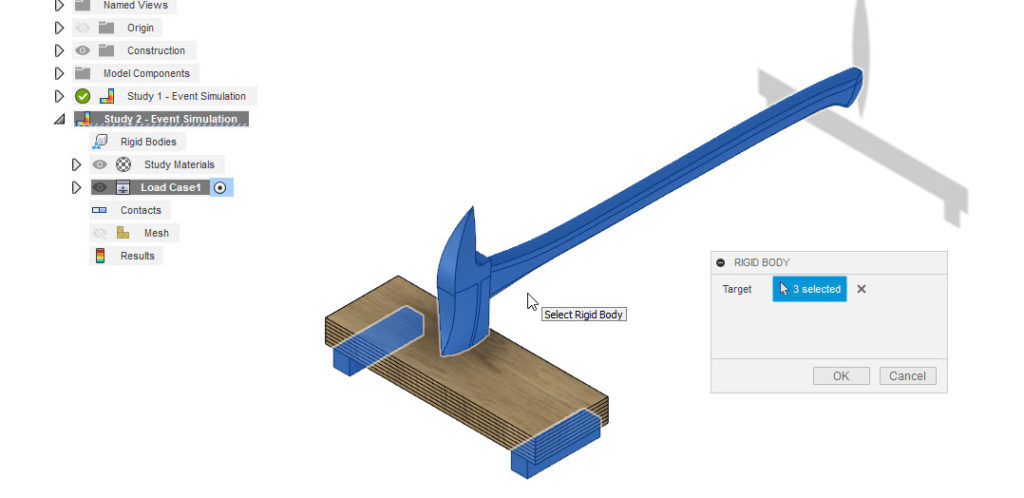

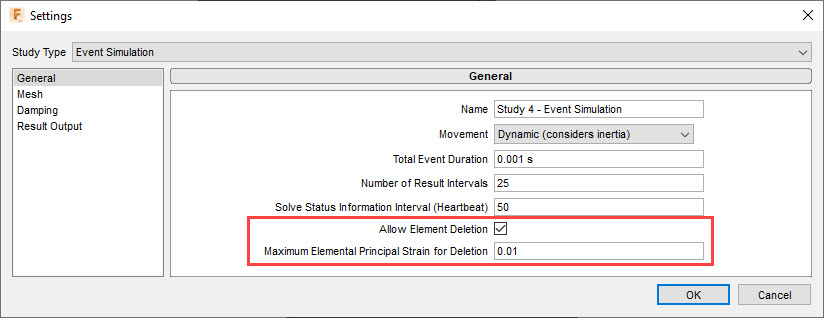

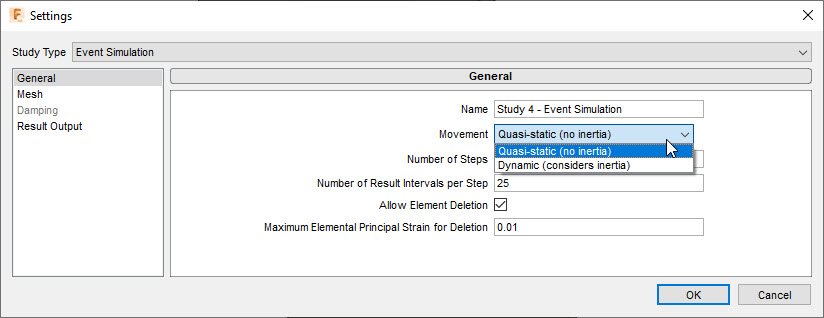

We are excited to add Event Simulation Analysis to our list of supported study types in Fusion 360. Event Simulation Analysis in Fusion 360 is powered by the accurate and trusted Autodesk Explicit Solver and can be used to solve complex explicit dynamics and specific quasi-static problems.

An Event Simulation study can be used to simulate time-dependent, dynamic events where the effects of velocity, acceleration, damping, and mass are essential. This is ideal for modeling problems that are transient in nature, involve large deformation, are contact dominated (Multi-body), involve impact, and/or have highly non-linear material behavior. Loads can be applied as a function of time, and results are output at actual instantaneous time points during the event, rather than at arbitrary increments in a static analysis.

Like Nonlinear Static Stress analyses, Event Simulation studies can account for material and geometric nonlinearities.

Event Simulation Examples

The following list contains a few examples for which an Event Simulation might be appropriate:

Key Event Simulation Features

All simulation attempts to answer the ultimate engineering question “What-if”. Now with Event Simulation, Fusion 360 can help you get your next project done, right the first time, without that nagging “What if” question hanging over your head. Even better, this study is solved using cloud computing, freeing up your computer for other tasks. To familiarize yourself with Event Simulation tools and workflows, please refer to these Tutorials. To learn more about Event Simulation, please refer to our help page.

Start simulating today and download Fusion 360 now.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.