Explore the importance of strong visuals for inventory management and how MES provide teams with the necessary data to succeed.

Every day, computers create more than 2.5 quintillion bytes of data – that’s a lot! With so much information at your fingertips, it can be difficult to know which data provides value to your business.

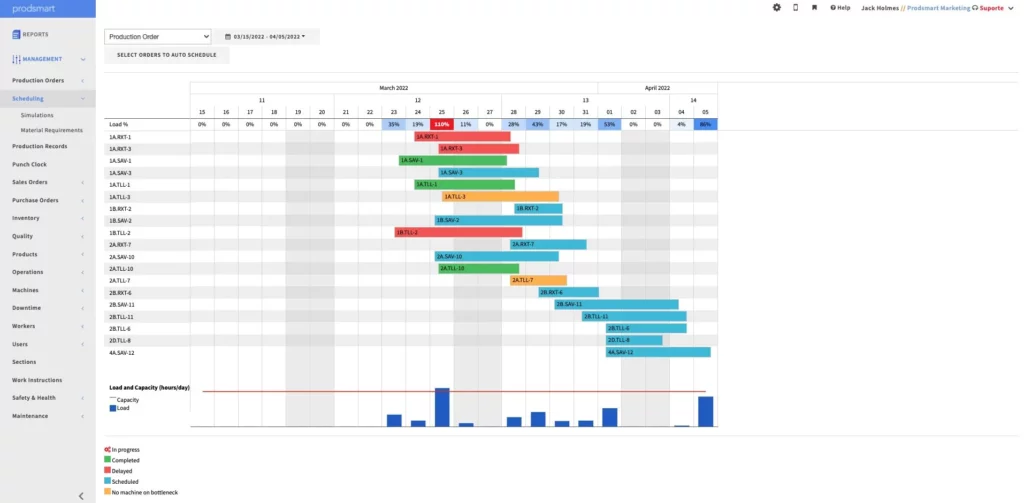

That’s where good visuals come in. Software that turns cold, hard data into colorful charts, graphs, and graphics provides you with the insights you need to make smarter inventory management decisions.

Most people are visual learners

Research shows that people are more likely to remember information when it accompanies visual content. One study suggests that the brain processes visuals 60,000 times faster than regular text.

What does this mean for your organization?

When it comes to inventory management, raw numbers can be difficult to decipher. Using visuals, however, will help you make sense of complicated information. You are more likely to remember this information in the future, too.

Using a Manufacturing Execution System (MES) with visuals will help you track inventory workflows and make it easier to reorder the products and materials you need to facilitate your production processes. It’s as simple as that.

Visuals help you gauge supply and demand

Inventory management is all about supply and demand. However, without the latest visual metrics, it can be tough to manage your inventories properly and anticipate demand from customers and suppliers.

With an MES system that utilizes visual content like diagrams and graphs, you can visualize your workflows and improve your production systems. You can color-code important data sets, for example. This will allow you to see which products are running low on stock.

Visuals make things easier for your team

If your team has to grapple with too many inventory management metrics, they could make mistakes or miss key information. Visuals, on the other hand, make it easier for your team to see the most valuable data in one place, without having to rely on several different platforms.

With a good MES, you can prioritize tasks and avoid overload on the shop floor. You can share these visual reports with different departments in your organization or with suppliers and clients. As a result, you can improve the way you manage your inventories and fulfill orders.

Looking for an MES with visuals to optimize inventory management? Try Fusion Operations today: