With the Xometry Add-in for Fusion 360, you’ll be able to save time on ordering customer parts, get instant pricing and lead times, and instant manufacturability feedback.

What is the Xometry Add-in for Fusion 360?

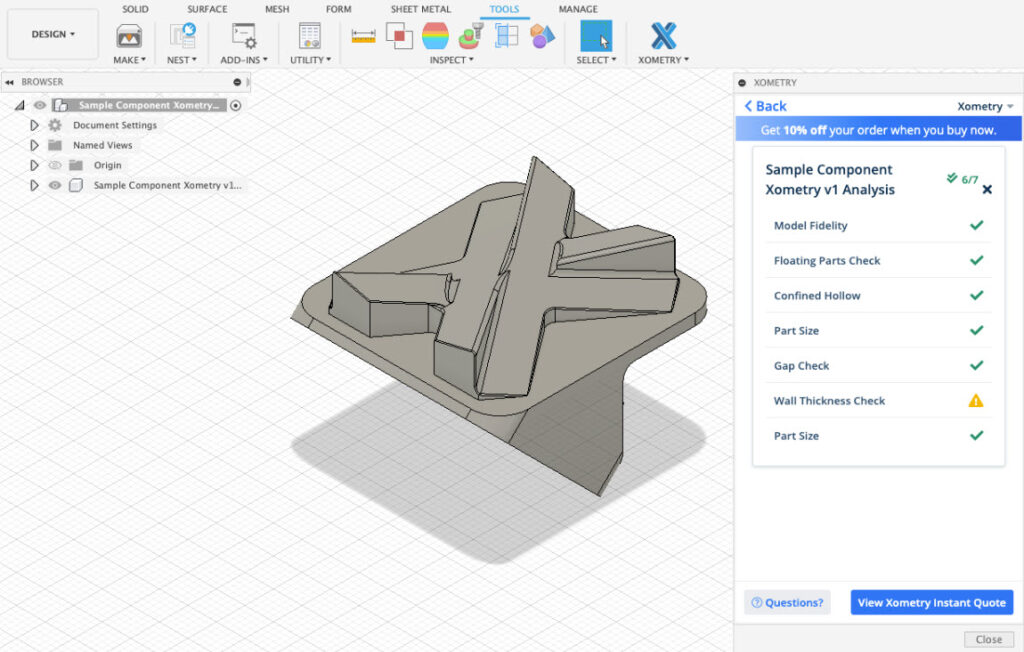

Xometry’s add-in for Autodesk Fusion 360 analyzes the geometry of the CAD design. It then allows you to select the material, process, and quantity to get real-time pricing and lead times, all from within Autodesk Fusion 360. Additionally, the add-in checks for and visualizes potential DFM (design for manufacturability) issues, helping designers optimize their design for manufacturing.

This seamless integration of custom manufacturing feedback and instant quoting allows engineers and designers to see the impact their design choices make on budget and product development timelines. With the click of a button, users can finalize their custom parts and order from Xometry online.

You can download Xometry’s add-in for Autodesk Fusion 360 directly from the Autodesk Fusion 360 app store.

What is visual DFM feedback?

Visual design for manufacturability (DFM) feedback is a new feature to Xometry’s add-in for Fusion 360 that perfectly compliments the existing DFM features of the app and takes them to the next level. Utilizing a built-in 3D viewer, users can quickly and easily review design feedback and navigate to areas of concern.

Visual DFM will highlight the faces and edges of potentially troublesome features directly in the part of the viewers’ 3D model so designers can focus and pinpoint their efforts. Our visual DFM will bring attention to issues such as:

- Thin walls

- Inaccessible areas

- Non-manufacturable features

- Process size restrictions

- And more!

Why is it important to review DFM feedback?

Reviewing design for manufacturability feedback is vital for several reasons. One of the most important reasons being it is an early warning of potential downstream issues that could otherwise jeopardize a project’s success. A design with manufacturability issues can bring projects to a halt and require last-minute design changes to be made, slowing down manufacturers and introducing delays to the timeline.

Another reason for reviewing DFM feedback is to drive lower costs. Difficult-to-manufacture features often result in higher costs as they can take more time to produce and require specialized processes, such as EDM or broaching, in the case of sharp interior corners in CNC parts. Thankfully, Xometry’s visual DFM makes it easy to spot these issues upfront so you can resolve them before they pose a bigger problem.

What are some other benefits of Xometry’s visual DFM?

Xometry’s visual DFM feedback benefits do not stop at helping designers identify problematic features. Here are a few other ways you can use this feature to your advantage:

- Easily check the feasibility of your design in different manufacturing processes and materials by changing your selections in the add-in and checking the DFM analysis.

- Review DFM recommendations that update according to the design rules for the selected manufacturing process and material.

- Make informed design decisions to optimize cost and lead times.

- Share visual feedback with your colleagues, designers, and engineers to facilitate productivity and communication.

Get started with the Xometry Add-in for Fusion 360

Start seeing the direct impact of design changes on your part’s cost and manufacturability without leaving Fusion 360.