Recently, we had the opportunity to sit down with company cofounders Hahna Alexander (CTO) and Matthew Stanton (CEO) to talk about how over the past two years they’ve transformed Pittsburgh-based SolePower from a Carnegie Mellon undergraduate engineering project into a rapidly-growing technology startup. In this post, we’ll talk about the real-world problem they’re solving with their product and how they have iterated the design of the product to get it ready for manufacture. A follow-up post will address the challenges they’ve faced in making SolePower not just a clever idea, but a viable commercial business.

Design Inspiration: Finding the Right Use Cases

SolePower is a shoe insole that generates power every time you step on it so that you can charge your phone or other portable electronic device simply by walking. Alexander explains that she and Stanton hit on the idea during a senior design project in the mechanical engineering department at Carnegie Mellon. She says that the two of them “were sort of put together [in a group] by accident.” Their professor told their team to solve a problem that students faced around campus every day. After going through “a lot of really bad ideas,” Alexander says, they thought of a device that would charge lights on students’ shoes at night; students would be able to see where they were going, and they would be seen better by motorists. After demoing the idea, they realized that such a device could also store power to be used for portable electronics.

Alexander stresses the importance of finding a challenge that really needs solving if you want to start a business. “From the start,” she says, “we were trying to develop a technology that would solve a fundamental universal problem faced by people all over the place, around the world. And that’s a really important lesson for a startup: your product needs to solve a problem.”

As they extended their work beyond students on campus, the SolePower team uncovered three significant use cases for their product:

- Generating Power while Hiking the Trails — Stanton has been an avid backpacker for years, and the team is looking to outdoorspeople as a key group of early adopters. Hikers often carry extra sets of batteries, along with solar collectors that don’t work well in forests or under overcast skies, all in hopes that they will have a reliable source of power for their cell phones and GPS devices. But what’s more reliable for a hiker than walking? Stanton explains that SolePower “can slip into any shoe, similar to a normal insole, and then after an hour of walking you get two and a half hours of talk-time back on the device.” That’s a boon for hikers who need to stay connected to the outside world from the backcountry. As Alexander puts it, “the idea is to reduce the amount of weight that they have to carry, but also provide a critical backup safety source.”

- Bringing Personal Power to the Developing World — When the two co-founders first demoed their insole at an event in Washington, D.C., they were approached by members of humanitarian groups who pointed out its huge potential for the developing world. Alexander explains that there are about a billion people in the world who lack access to reliable electricity, including 230 million in sub-Saharan Africa alone. Throughout that region, cell phones have become a vital part of everyday life: people rely on them for financial transactions, healthcare information, and weather and pricing information relevant to farming. Stanton notes that people there often walk miles per day and spend a substantial portion of their income simply to keep their phones charged. “With SolePower,” he says, “they don’t have to do that anymore.”

- Lightening the Load for Military Troops — SolePower is also working with the U.S. Department of Defense to reduce the amount of weight that troops must carry in their packs. These days, footsoldiers often carry more than 20 pounds of batteries for a single-day mission. Multi-day missions mean even heavier loads, and Stanton says that 120-pound packs aren’t uncommon. Given that these troops are walking many miles a day, the SolePower team hopes to reduce their pack weight significantly.

There’s a potentially much broader use case, of course, for any consumer who walks a lot each day and finds that their mobile devices tend to run low on juice. But these three niches provide great starting points for SolePower to build its market presence.

Product Iteration: Creating a Real Solution

From the beginning, Alexander and Stanton faced the particular design challenge of creating a complex mechanism in a tiny space — the fraction of an inch represented by the height of a shoe insole. “It’s a really complicated problem,” Stanton says, “creating power from a step in such a small profile. It’s a lot of force, but you really don’t have a lot of distance to travel to create that force, or to harness that force and turn it into energy.” Those factors make it hard to create a product that will be not only efficient, but also durable and reliable.

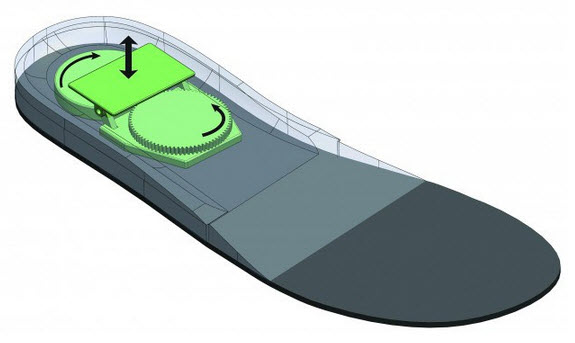

Alexander explains that the device works by taking the linear motion of each step and converting it into rotational motion, which spins a small electromagnetic generator embedded within the insole. The power that’s generated feeds up through a wire into a battery pack, which is tied either to your shoelaces or around your ankle. Their very first design, she says, was an inch and a half tall, “super uncomfortable,” and fragile enough that it broke after a mile of walking. After a full redesign and six months of iteration, they were able to reduce the height to 3/8 of an inch by taking vertically oriented components and realigning them horizontally. Further design iterations increased the efficiency of the generator and the durability and comfort of the insole.

Now the team is using Fusion 360 to refine their design as the product nears its market launch at the end of 2014. Fusion 360 has made it far easier for them to model the organic shapes required by the insole’s curves. “Instead of extruding up with solid blocks,” Alexander says, “you’re starting with the shape and pulling different dimensions to where they need to be. So we found the most comfortable and effective way to put our mechanism into the insole and get a nice fluid curve so it was both comfortable and short.”

The software also helps the four engineers on the team collaborate better; each of them can leave notes on any part that they change. As Stanton puts it, it’s easy to inform your teammates: “Here’s the part. Here’s what happened in the last 5 minutes to it, please read it before you open the part.”

Refining Designs for Manufacturing

The back-and-forth communication among team members reflects SolePower’s constant evolution of the insole. “For any product,” Stanton says, “there’s a massive iteration process that needs to be worked through.” You have iterate quickly — and many times over — to incorporate the feedback of test users, ensure that each part can be manufactured properly, and improve the design process itself. Alexander notes the importance of virtual prototyping: “You can’t physically prototype everything you need to prototype without doing it virtually.” Using Fusion 360, the team is able to “make parts very quickly, iterate quickly, see how they’re going to work in a virtual environment, and then take the best option and build it.”

3-D printing also plays an important role, as Stanton explains. “We use 3-D printing all the time to quickly get parts back. The majority of it we use for checking the geometry to make sure that we’re within the tolerances before we send it out. So we have an in house 3D printer that we use for geometry fits, and then we’ll go in contract out to a professional 3D printer to make sure that we have the parts that we need, and they’re of the right quality so that we have something that works. And, you know, the turn times and the cost are much cheaper to get something that’s 3-D printed, and you can get amazing tolerances when compared to doing a machining process. Some of our parts, we wouldn’t be able to make any other way.”

As for manufacturing, Stanton advises hardware startups to keep it close to home, at least initially. The company found an experienced injection molding company just a couple of hours away in Erie, Pennsylvania. “We’ve worked with them really closely to make sure that our tooling costs are kept low,” Stanton says. SolePower also works with an electronics supplier in Pittsburgh and a manufacturing company in Rhode Island. The logic for working with local vendors is simple: “It’s nice to have them all fairly close, in case there are issues. And no matter what, if you’re making a product for the first time, you’re going to have issues.”

As the SolePower team brings their product to market, Alexander says, she’s most excited about “getting the insole into people’s shoes and seeing this idea that started out as sketches on paper almost two years later, working and charging cell phones and GPS and other things that people need.”

In the follow-up to this post, we’ll talk about the specific business challenges that Alexander and Stanton have faced during that two-year journey as they have pursued funding, built their team, and worked to get their product ready for the consumer marketplace.