& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

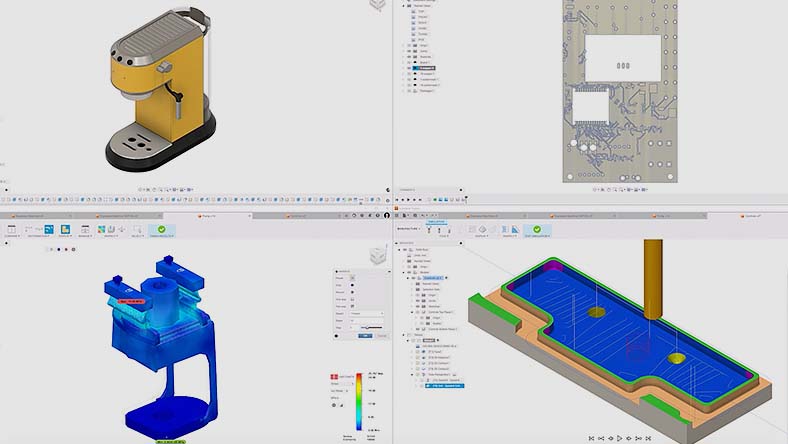

Autodesk Fusion offers a comprehensive set of design tools that allow you to go from idea to prototype to manufacturable 3D model, all in one product development solution.

Parametric modeling enables you to easily define and modify your designs by changing parameters and dimensions. Both solid and surface modeling techniques allow you to create intricate and realistic models.

Easily collaborate with your team, clients, and stakeholders anytime, on any device. Reduce the amount of re-work and feedback cycles needed to bring quality products to market faster.

Quickly explore your ideas to uncover the best concepts earlier in the design process with a comprehensive set of flexible 3D modeling tools.

Rapidly prototype to help identify and address design issues early on. Perform various simulation analyses to test your product's performance.

Collaborate in real-time and take full advantage of tools such as parametric modeling, simulation, and automated workflows to streamline the design process.

Reduce re-work, production costs, material waste, and manufacturing errors with design for manufacturing tools.

Design your way with a comprehensive set of 3D design tools including intuitive parametric, freeform, direct, and surface modeling.

Create high-quality, photo-realistic images of your designs to visualize the final product. Apply realistic material appearances, including textures, finishes, and colors using the comprehensive materials library.

Validate and optimize your designs for various real-world scenarios. Identify potential issues, improve performance, and reduce material waste before moving to the manufacturing stage.

Explore multiple manufacturing-ready outcomes that meet your design specifications while reducing weight, improving performance, and consolidating parts through generative design.

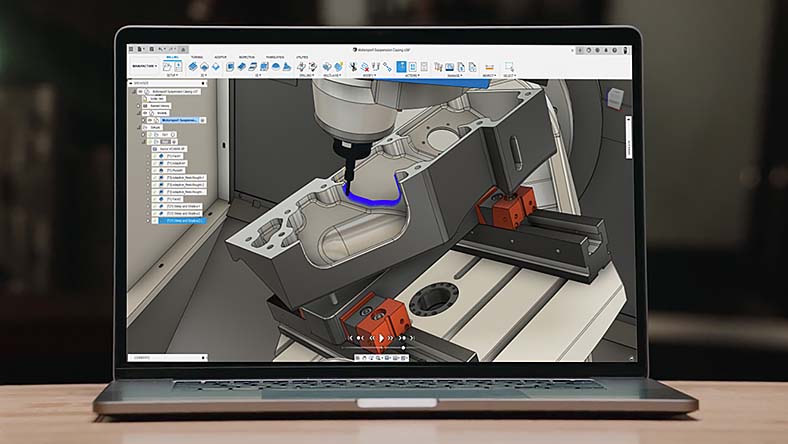

Consider machining, tooling, and material constraints while creating 3D models, and help make sure that designs are practical and cost-effective to produce. Eliminate the need to switch between different software applications, reducing potential errors and saving time.

Remove the silos from your traditional design process and use a modern collaboration environment. Connect your teams and clients, communicate in real-time, and centralize project activity.

Turn your concepts into 3D models 4x faster when compared to traditional industrial design software.

Create photo-realistic renders of your designs up to 75% faster to expedite stakeholder buy-in.

Create high quality products and accelerate time to market by 60%.

Source: Lifecycle insights report

Experience the power of unified design and manufacturing tools with integrated product data management with Autodesk Fusion.

Fusion manages data in the background while teams stay focused on product development. Eliminate time spent searching for files or losing work. With Fusion, data is always centralized, accessible, and secure.

1-year subscription: most popular, 1-year access to advanced CAD, CAM, CAE, PCB, data management, and collaboration tools with Autodesk Fusion.

1-year subscription: Combines core capabilities in Autodesk Fusion with professional-grade tools in the Design, Simulation, and Manage Extensions to advance your design process.

Connect with a representative to discuss Autodesk Fusion and find the solution that best fits your company’s product development needs.

Extensions allow you to unlock advanced design and manufacturing technologies in Autodesk Fusion.

Want to try Autodesk Fusion? Download a free 30-day trial

Don’t settle for a siloed approach. See how an integrated CAD, CAM, CAE, and PCB software platform delivers unprecedented value to designers, engineers, and manufacturers.

This guide highlights important tools to be aware of, best practices, and tips to get you up to speed with the design workspace.

Learn how Autodesk Fusion offers a unified, streamlined, and highly collaborative product development environment—from prototype to final product.

Explore how design automation tools like parametric modeling, generative design, and automated modeling in Autodesk Fusion enable your team to grow smarter.

Explore the benefits of DFM and discover which Autodesk Fusion features support the process.

Here are 10 ways Autodesk Fusion supports designers and engineers during the prototyping and fabrication stages of product development.

Learn how configurations are an invaluable tool, offering a streamlined approach to design optimization, risk mitigation, and cost efficiency.

Here are some key aspects of industrial design:

Functionality: Industrial designers focus on the functionality of a product, making sure it performs its intended purpose effectively.

Aesthetics: Designers also focus on the visual appeal of the product, including its shape, color, and texture. The goal is to make the product attractive to potential customers.

Ergonomics: This involves designing products in a way that they are comfortable and efficient to use. It involves understanding how the product will interact with the user and their environment.

Manufacturability: Industrial designers need to consider how the product will be manufactured. This includes understanding the materials to be used, the manufacturing process, and the cost implications.

Sustainability: With growing awareness about environmental issues, many industrial designers now also consider the environmental impact of the product during its lifecycle. This includes its energy use, waste produced, and end-of-life disposal.

User Experience: This involves understanding and designing the entire experience of a user with the product. It includes the way that the product is used and the emotional response of the user to the product.

Industrial design software refers to a range of 3D modeling and CAD tools that are used by industrial designers to create, modify, analyze, and optimize design solutions. Software tools like Autodesk Fusion help designers visualize, simulate, and render product designs before they are manufactured, saving time and resources.

Yes, Autodesk Fusion is not only a 3D design and modeling tool, but it integrates computer-aided design (CAD), computer-aided manufacturing (CAM), and computer-aided engineering (CAE) in a single platform. This allows for seamless transitions between designing, testing, and manufacturing.

Yes, Autodesk Fusion does include simulation capabilities. These tools allow designers and engineers to test and validate their designs under real-world conditions without having to create physical prototypes.

Here are some of the key simulation features in Autodesk Fusion:

Static Stress: This allows you to simulate the effects of forces, pressures, and other loads on your design to see how it will respond and where the weak points might be.

Modal Frequencies: This simulation helps you understand the natural vibration frequencies of your design, which is important in avoiding resonance and potential failure.

Thermal Stress: This simulation allows you to see how changes in temperature will affect your design.

Structural Buckling: This helps you understand how and when your design might buckle under compressive loads.

Shape Optimization: This tool uses the power of the cloud to help you find the best design to meet your criteria, removing material where it's not needed and adding it where it is.

Event Simulation: This allows you to simulate the physical movements of your design. For example, simulating the opening and closing of a lid or the movement of a mechanical arm.

3D design and modeling software plays a crucial role in various industries. Here are some reasons why it's important:

Visualization: 3D design software allows designers to create realistic models of objects or structures, which can be viewed from any angle. This helps in better understanding the design, identifying potential issues, and making improvements.

Accuracy and Precision: These tools provide high levels of accuracy and precision in design, which is crucial in fields like engineering and architecture.

Efficiency: 3D design software can significantly speed up the design process. Designers can quickly make changes to the model and see the effects immediately, saving time and resources.

Simulation: Many 3D design tools include simulation features, allowing designers to test how their design will perform under real-world conditions. This can help in identifying and addressing potential issues before the production stage.

Collaboration: Many 3D design software options are cloud-based, allowing multiple team members to work on the same design simultaneously, regardless of their location. This facilitates better collaboration and faster project completion.

Cost Savings: By allowing for thorough testing and validation before a physical prototype is built, 3D design software can help save costs associated with physical prototyping and manufacturing.

While there isn't a one-size-fits-all answer, Autodesk Fusion is a cloud-based 3D modeling software that integrates CAD, CAM, CAE, and PCB into one package at an affordable price.

Product design is a process of identifying a market opportunity, clearly defining the problem, developing a proper solution for that problem, and validating the solution with real users. It involves a combination of understanding user needs, generating ideas, building and testing prototypes, and creating the final product with industrial 3D design software.

Yes, Autodesk Fusion is a highly versatile tool that is used for product design. It allows designers and engineers to quickly and easily explore visual and functional designs, create photorealistic renderings and animations, simulate and test how a design will work under real-world conditions, and translate designs into instructions for CNC machines.

Yes, Autodesk Fusion is an industrial 3D design software. It combines computer-aided design (CAD), computer-aided engineering (CAE), and computer-aided manufacturing (CAM) in one platform. It allows you to design, test, and fabricate in a single tool.