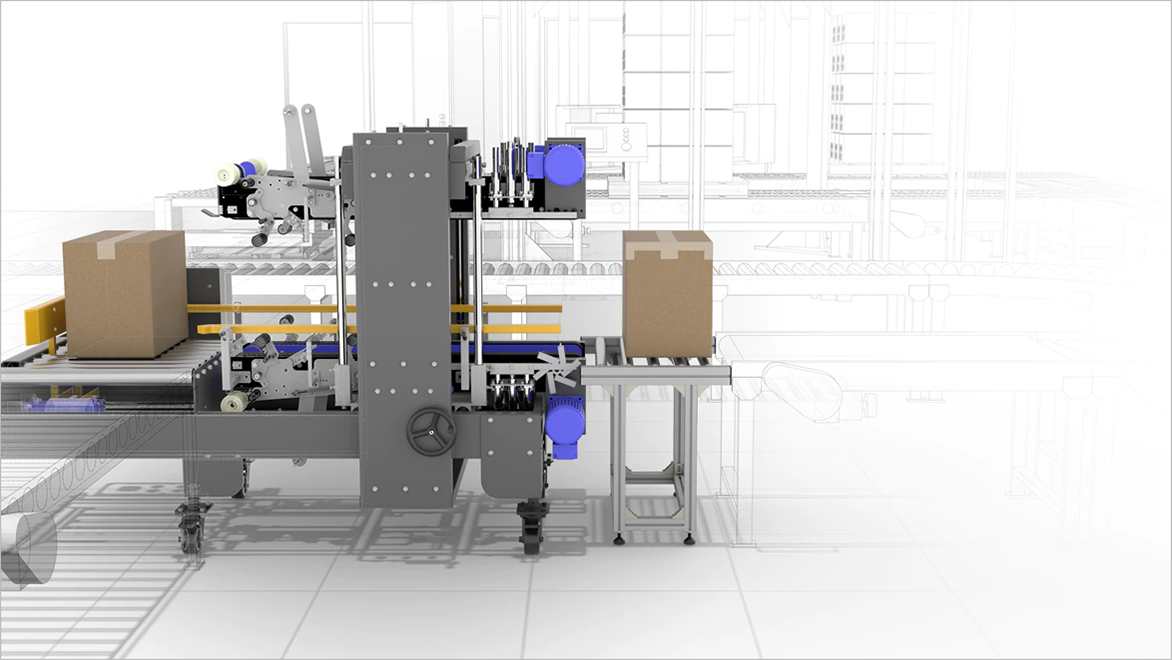

& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Achieve better outcomes for your products, businesses, and the world with intuitive, powerful, and accessible technology that connects every detail of your design and make process.

Autodesk empowers innovators to create smarter, more reliable machinery for their customers.

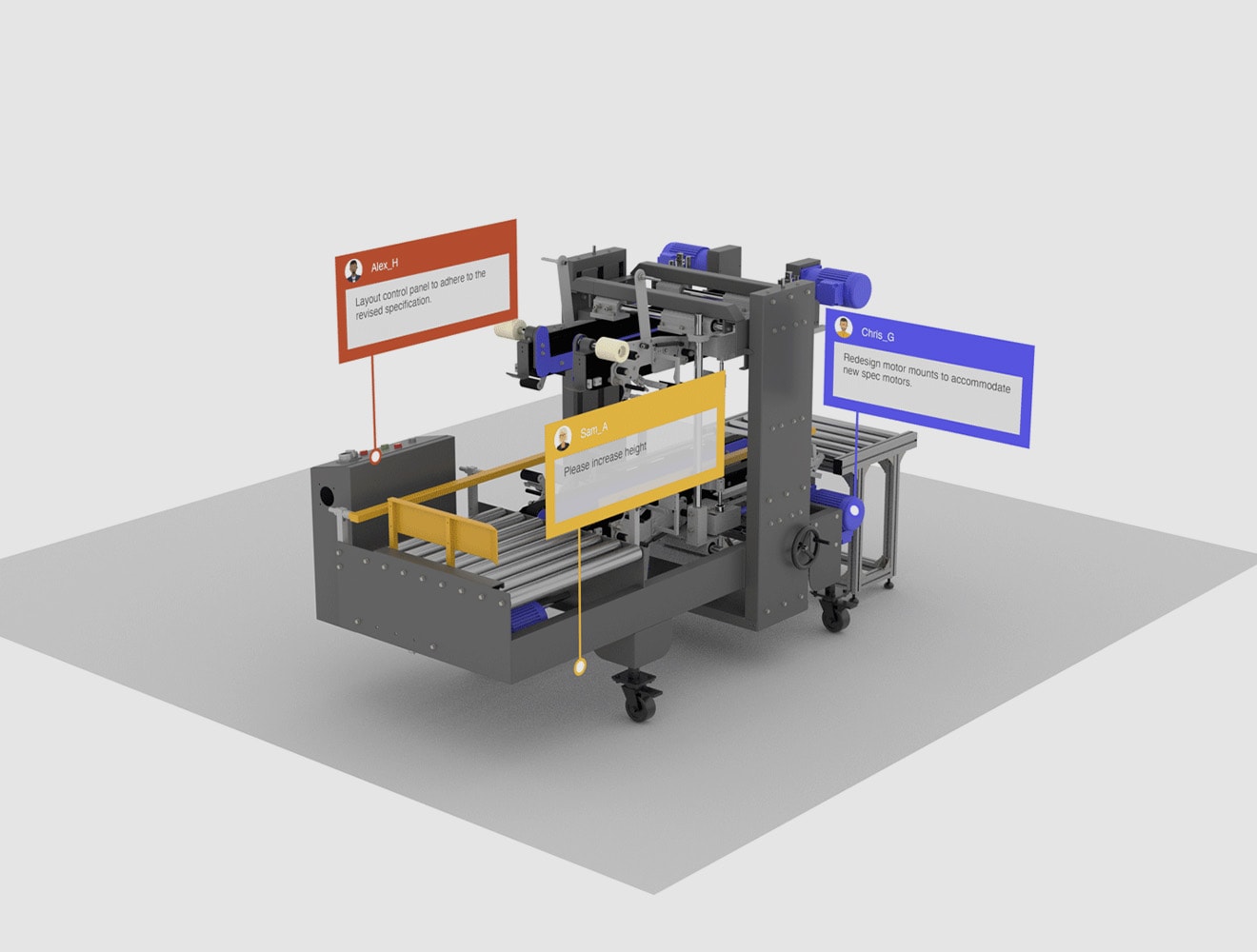

Easily find the information you need. Connect your colleagues, clients, and supply chain with a single, secure data model. Always know who’s responsible for the next step in your design cycle. Automatically maintain an audit trail of decisions and their impact.

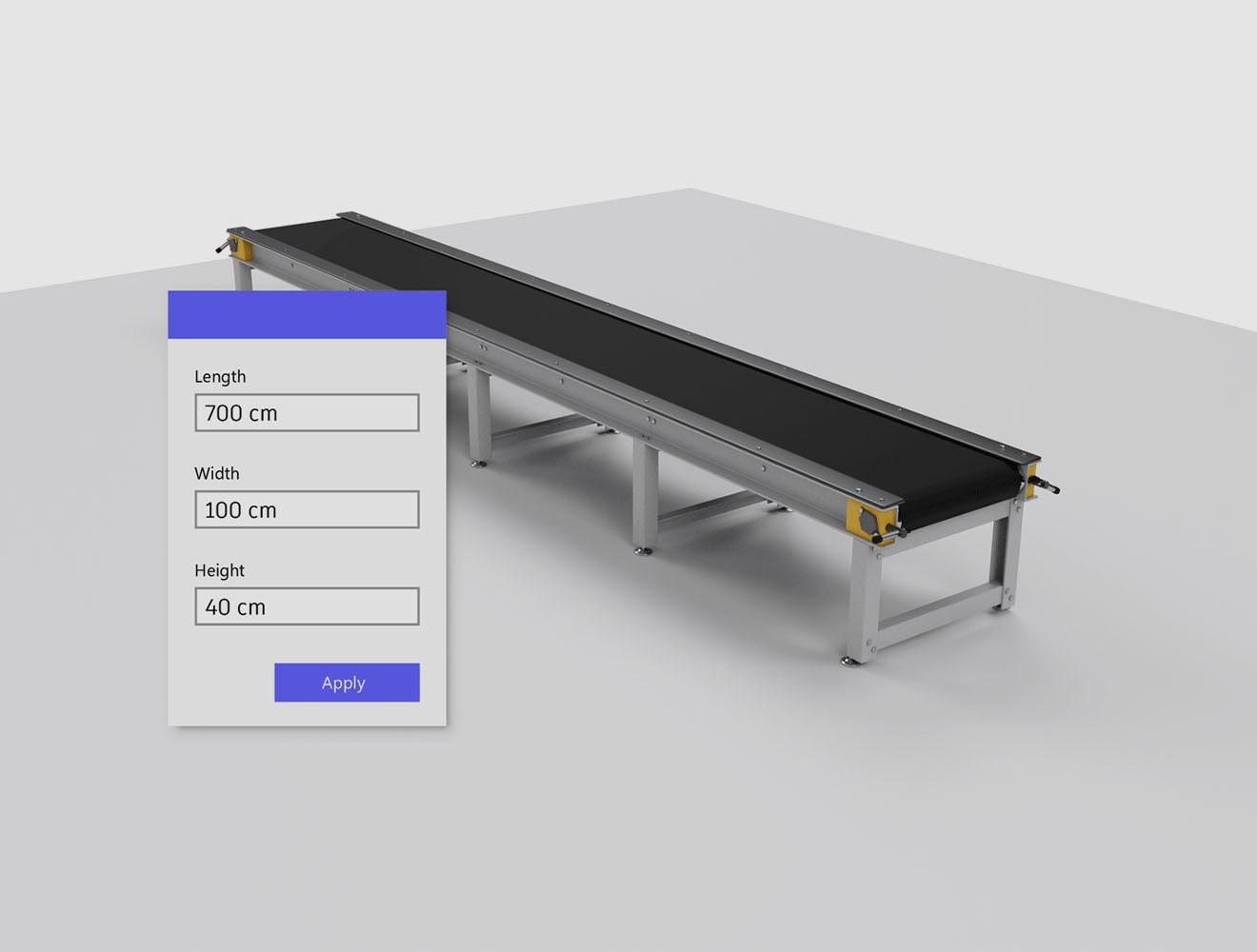

Improve quotation speed and accuracy using your existing CAD models to create sales configurators. Streamline everyday tasks to focus design and engineering time on creating innovative solutions. Automate manufacturing data preparation with BOM, nesting, and CAM in a single environment.

Bring together design and manufacturing using common CAD models to program CNC machines. Design fixtures and create toolpaths before engineering data is released— any changes automatically update CAM. Efficiently utilize production capacity across multiple machines and sites with standardized NC creation.

Autodesk solutions for industrial machinery and equipment manufacturers and suppliers.

Secure and control your intellectual property. Collaborate with your internal and external colleagues. Manage and track decision-making to automatically maintain your audit trail.

Use 2D and 3D side-by-side. Convert 2D drawings into associative 3D models. Make associative 2D drawings from 3D models and share as industry standard DWGs

Reference CAD data, and consume updates made by the authoring CAD tool. Seamlessly exchange CAD data from virtually any source while maintaining data integrity.

Discover professional-grade 2D and 3D CAD for design and engineering, including simulation, tolerance analysis, nesting, CAM, and production work cell design with factory planning.

Improve quality, avoid excessive machining operations, reduce variation, and improve collaboration between engineering and manufacturing, with easy analysis and reporting of component tolerance stack-ups.

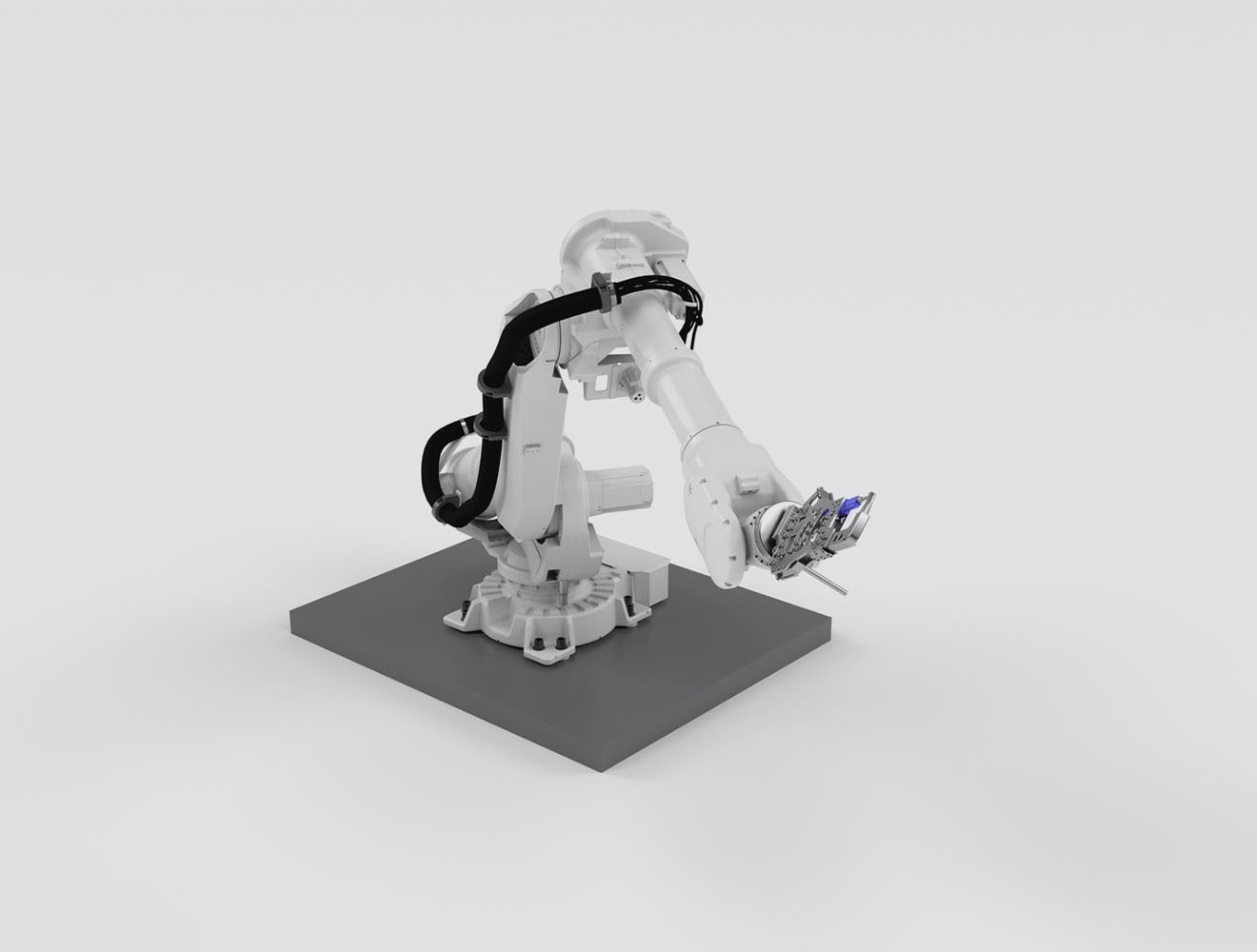

Predict, validate, and optimize your designs with accurate, trusted analysis - including mechanical FEA (*), computational fluid dynamics (CFD), plastic injection molding (*), composite materials, and manufacturing simulations.

*All links point to the US site.

Automate repetitive tasks. Capture and reuse engineering knowledge with a custom product configurator. Work more efficiently and create time to focus on imagination and innovation.

Make anything you want, however you want to make it. Unlock advanced capabilities for machining, additive manufacturing, generative design, nesting, and fabrication.

Minimize risk and maximize efficiency for production system and work cell design, from point cloud scanning and clash detection to production line simulation and installation sequencing.

Get Inventor + AutoCAD + Fusion + more—Professional-grade tools for product development and manufacturing planning

Powerful product design and engineering tools for 3D mechanical design, simulation, visualization and documentation.

Custom projects require a close relationship between equipment suppliers, clients, and external partners. But persistent weak spots in these relationships prevent future projects from starting on solid ground.

In this report, Forrester Consulting recommends a path forward for equipment suppliers.

Industrial machinery is equipment used for processing, production, and distribution in industries such as energy, liquid & gas processing, mining, construction, agriculture, forestry, manufacturing, machine tools, industrial robots, and building services equipment.

Examples of industrial machinery include:

The different types of manufacturing equipment can be categorized by industry, process, size, or method of operation:

Software is used in the manufacturing industry for design, simulation, data management, process management, project management, inventory and supply chain management, quality and safety management, and the control and monitoring of machinery.