AUTODESK FUSION

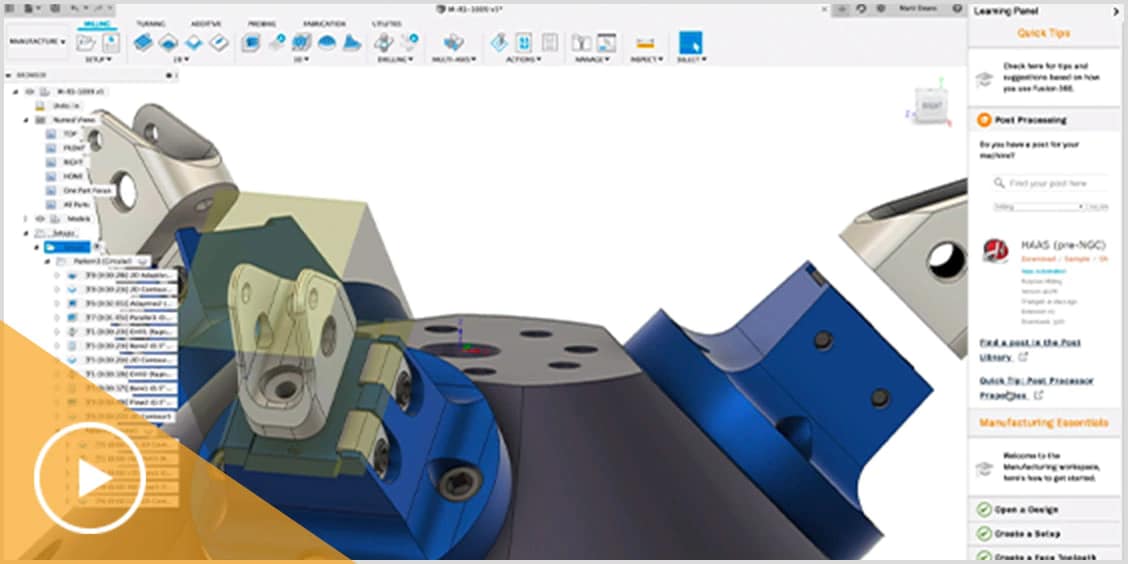

CAD/CAM software solutions in a single platform

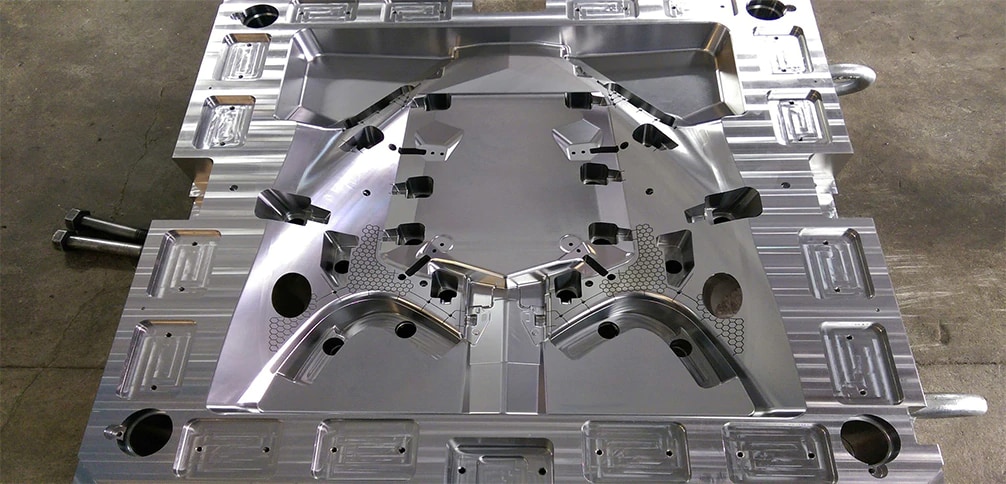

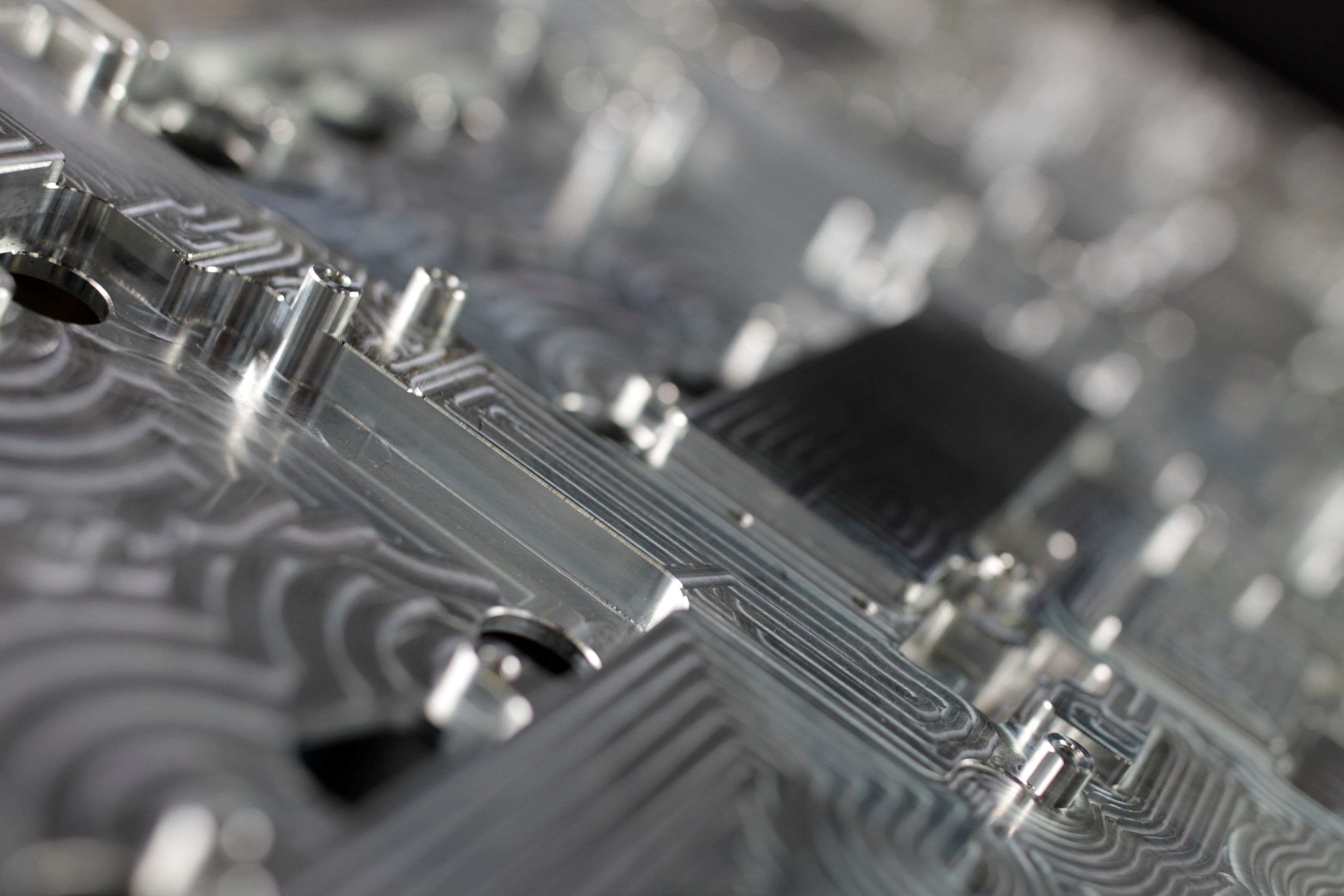

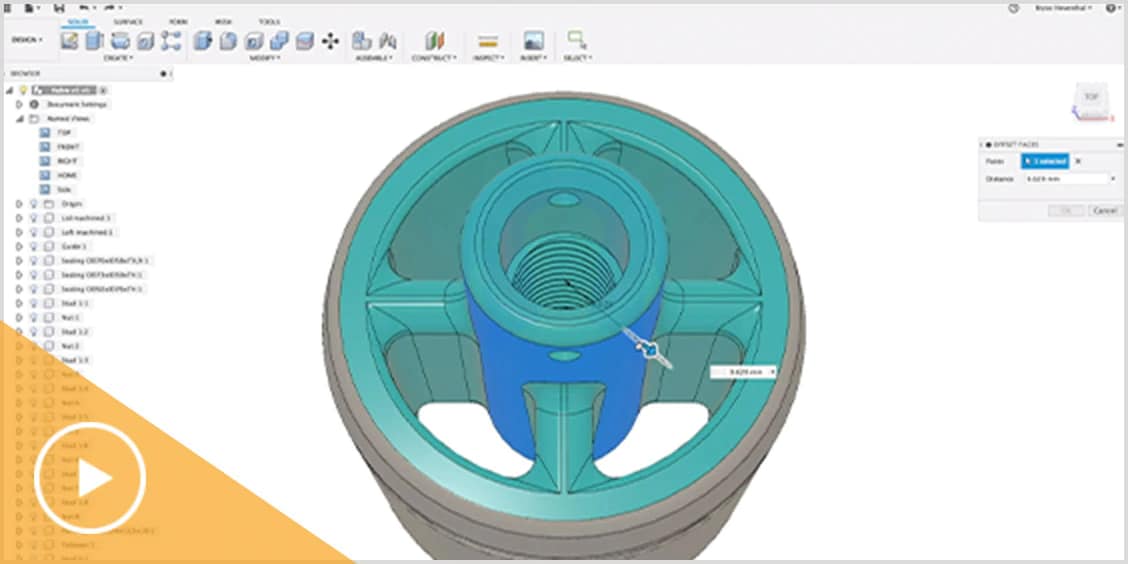

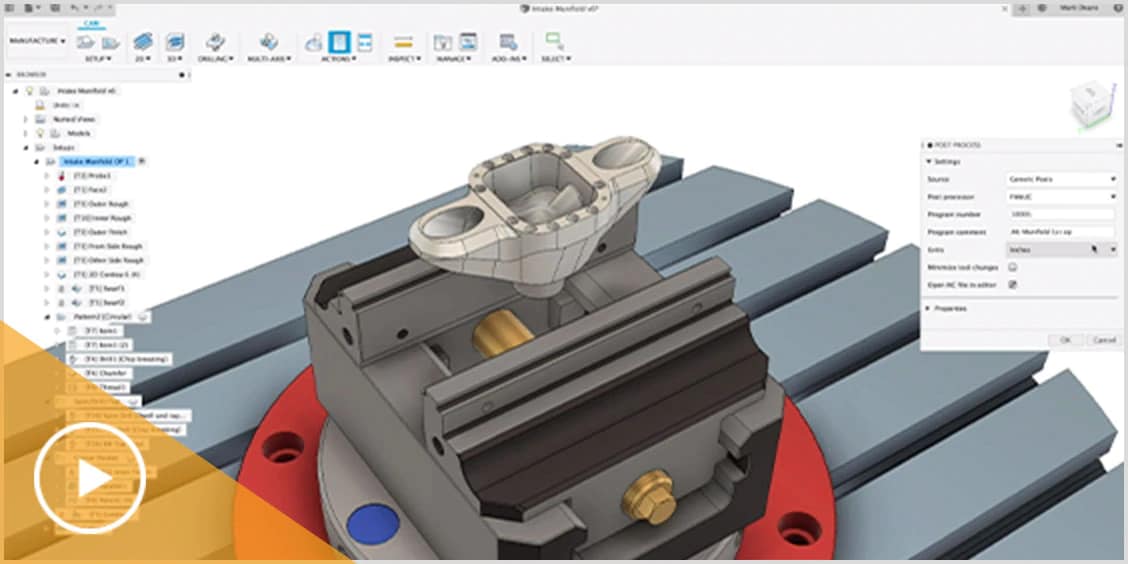

Using a single platform, Autodesk Fusion connects your entire product design and manufacturing process. Because it’s cloud-based, you may use this single tool to switch between CAD (design), CAM (manufacturing), CAE (simulation), and PCB (electronics) workspaces, as well as collaborate with your teams wherever you are. On this page, we'll look at how you may use free Autodesk Fusion CAD/CAM tools and courses to get a better understanding of the essential concepts.