& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

5-axis machining is a manufacturing process that uses computer numerical control (CNC) to move a cutting tool or part along five different axes at the same time. In addition to the standard three linear axes — X, Y, and Z — it includes two rotational axes that allow the tool to tilt and rotate. This means that the tool can approach the part from virtually any direction. This makes it possible to machine complex shapes, deep cavities, and intricate features in a single setup. As a result, 5-axis machining reduces the number of setups required, shortens machining time, improves surface finishes, and increases part accuracy. It is especially useful in industries where precision and efficiency are critical, such as aerospace, automotive, and medical device manufacturing.

5-axis machining offers significant advantages over traditional 3-axis methods by providing greater flexibility, precision, and efficiency. It allows the cutting tool to reach multiple sides of a part without the need to reposition it manually, which reduces the number of setups and the potential for human error. This leads to faster production times and more consistent results.

The ability to use shorter, more rigid cutting tools also improves surface quality and extends tool life. For complex geometries, undercuts, and parts with tight tolerances, 5-axis machining makes it possible to achieve results that would be difficult or impossible with other methods. It also helps manufacturers stay competitive by enabling them to take on more challenging projects, reduce costs associated with fixtures and rework, and deliver high-quality parts with speed and accuracy.

With Fusion, you can do both, seamlessly.

Whether you're running full 5-axis strategies or need fast, reliable 3+2 positioning, Fusion gives you the flexibility to machine your parts the way you want.

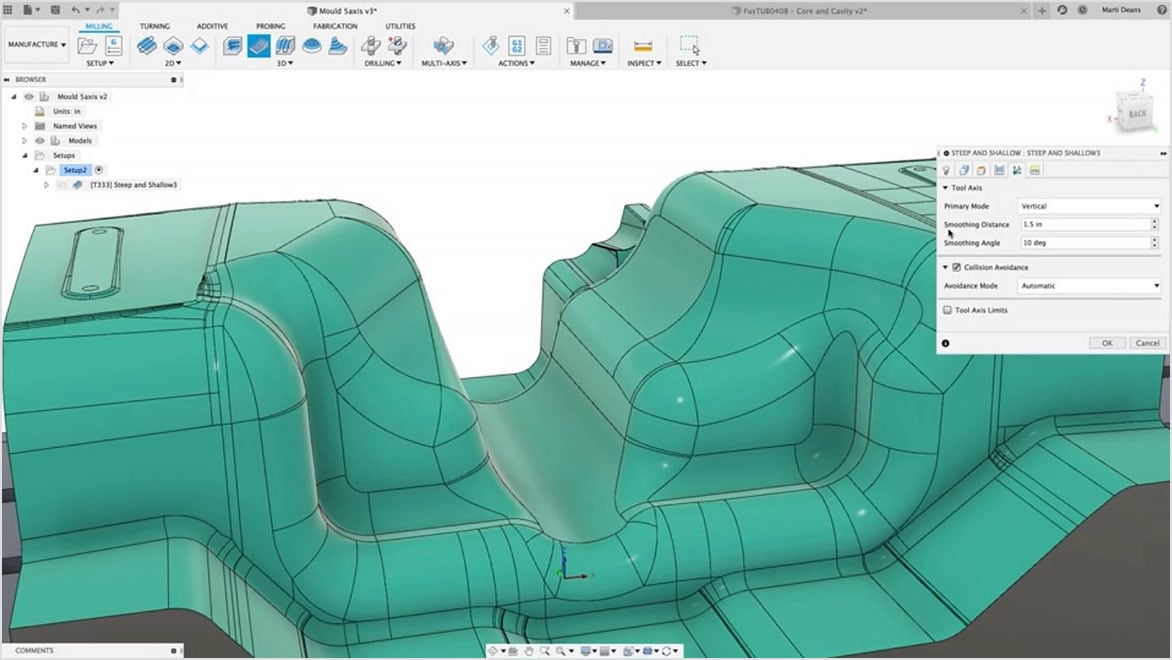

All five axes (3 linear + 2 rotational) move together, letting the tool follow complex surfaces smoothly—ideal for high-performance parts like molds and turbines.

Continuous motion

Complex geometry control

Superior surface finish

Requires advanced CAM strategies

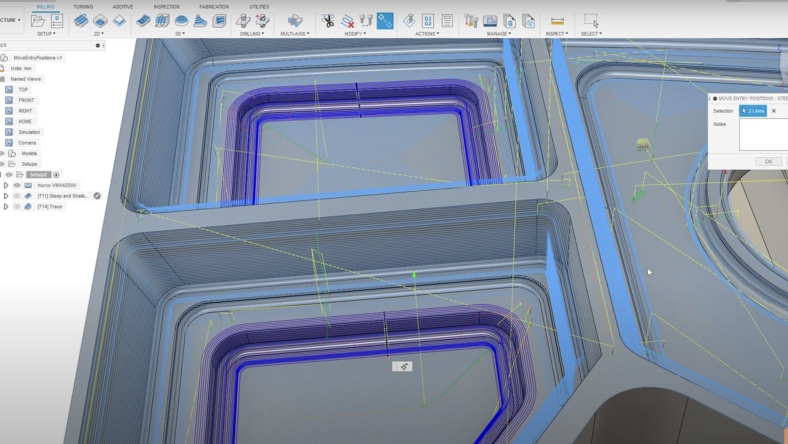

Rotational axes lock in place, then 3-axis machining begins—great for angled holes and multi-side features with fewer setups.

Fixed tool orientation

Simpler to program

Fewer setups required

Great for drilling and side features

Despite its power, programming 5-axis toolpaths can be intimidating.

Creating toolpaths for 5-axis machines requires advanced CAM software and a strong understanding of machining principles, making it more complex than 3-axis programming.

5-axis machines and supporting tools often involve a significant upfront investment, including machine cost, tooling, and software licensing.

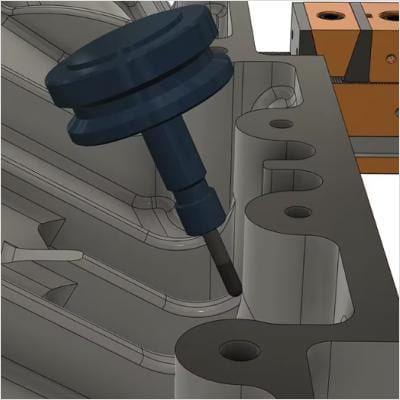

With more movement and tool angles, the risk of tool or fixture collisions increases, making simulation and verification essential.

Running 5-axis machines effectively requires highly trained operators and programmers, which can be a challenge for shops with limited expertise.

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

Fusion isn’t just about programming toolpaths, it’s about owning every step of your manufacturing journey, all within one unified platform.

Design with power and precision using solid, surface, and mesh modeling tools tailored to complex geometries.

Simulate real-world performance to catch issues early and ensure that your design is ready for manufacturing.

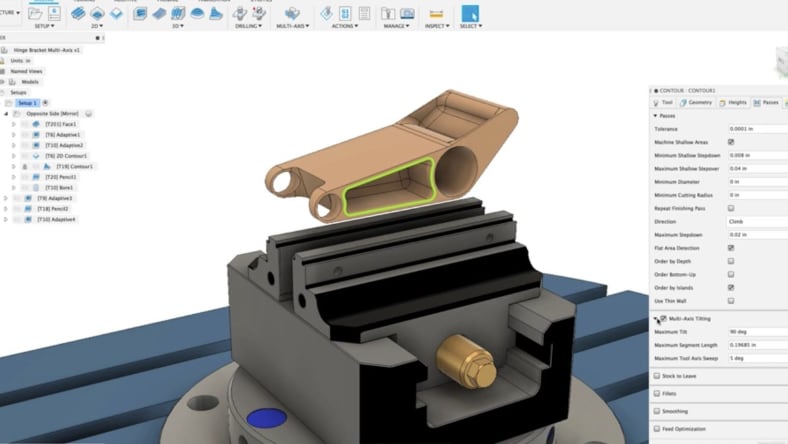

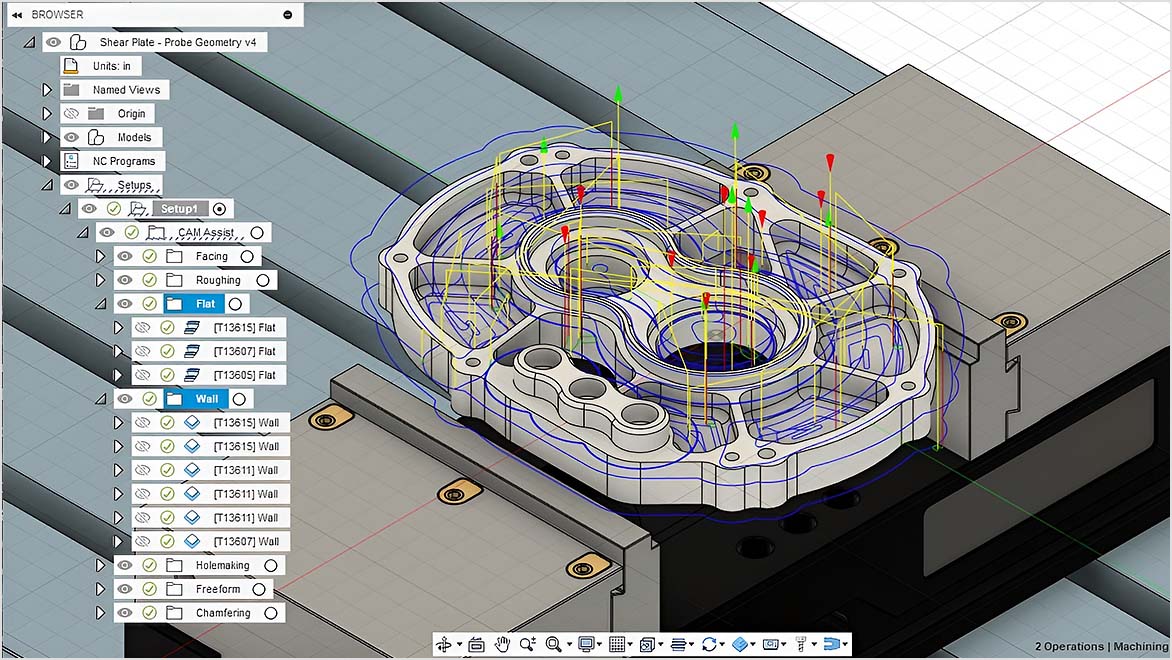

Generate intelligent toolpaths from basic 2D strategies to advanced simultaneous 5-axis motion.

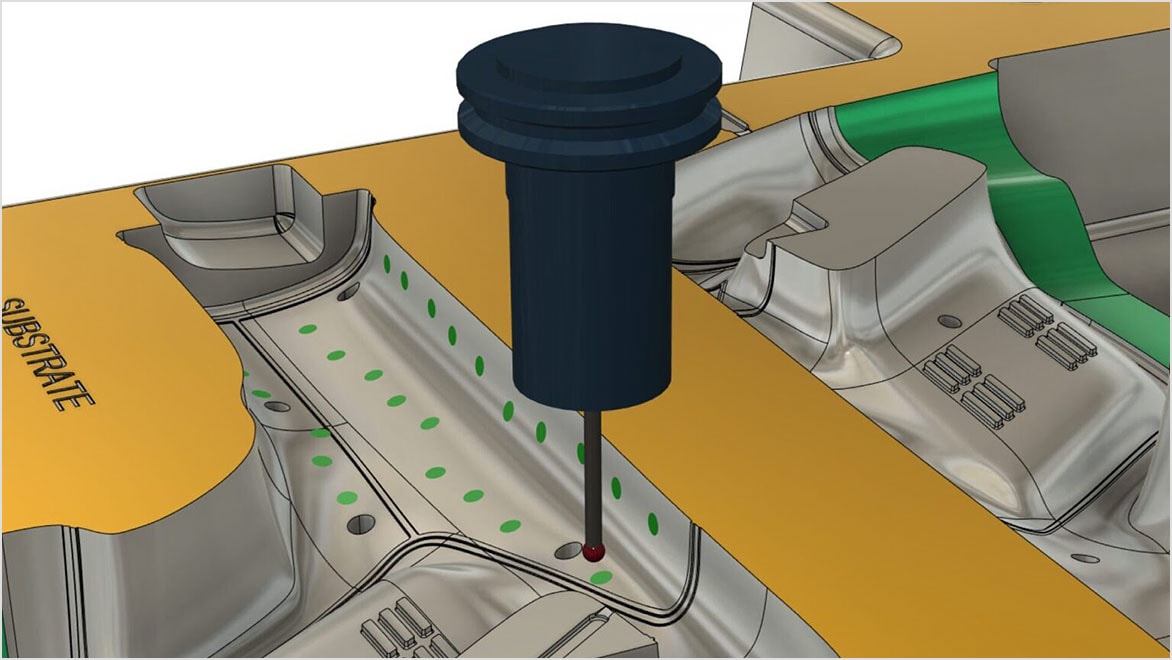

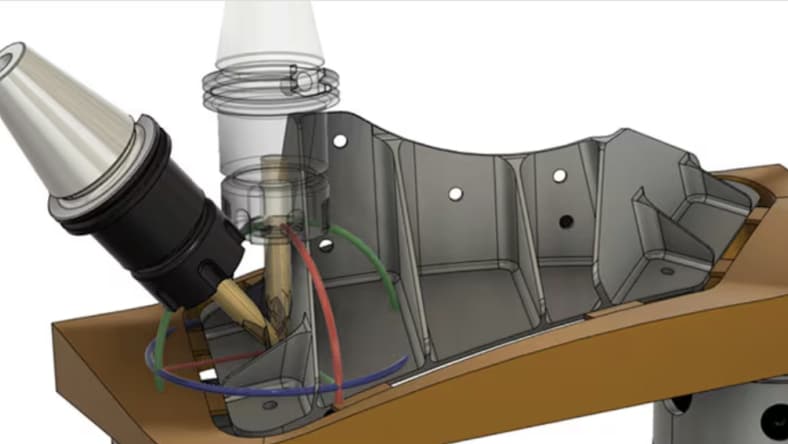

Post-process and validate your operations with machine-specific simulation and built-in collision detection.

Manufacture with confidence, knowing every step is connected and optimized for your machine, your part, and your workflow.

Combine 5-axis CNC machining with advanced programming to create complex, challenging components that add greater value to your offerings and impress customers.

5-axis machining minimizes setups and eliminates part transfers between operations, enabling faster production and helping you meet tight delivery schedules.

The flexibility of 5-axis machining allows use of shorter cutting tools and smarter strategies, improving precision and reducing or removing the need for manual finishing.

Fusion brings powerful yet approachable solutions to the most common 5-axis machining difficulties, helping you work smarter, faster, and with greater confidence.

Access advanced 4- and 5-axis strategies to program complex parts with full control over motion and orientation.

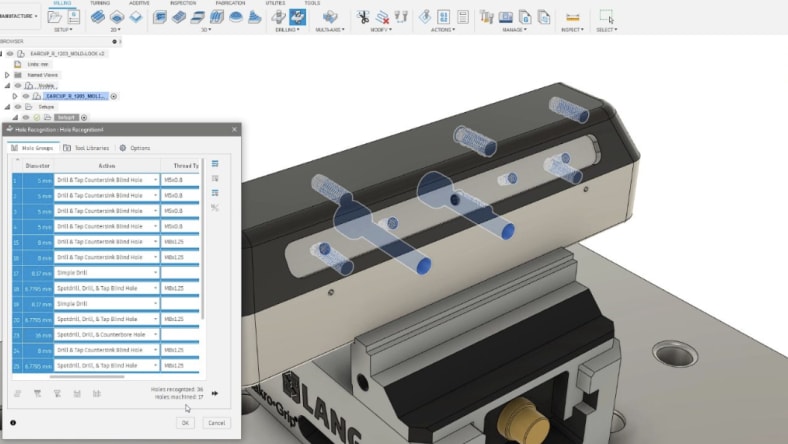

Easily automate 3+2 positional toolpaths to reduce setups and machine hard-to-reach features with precision.

Built-in detection auto-adjusts tool angles to avoid crashes and protect your tools, parts, and machines.

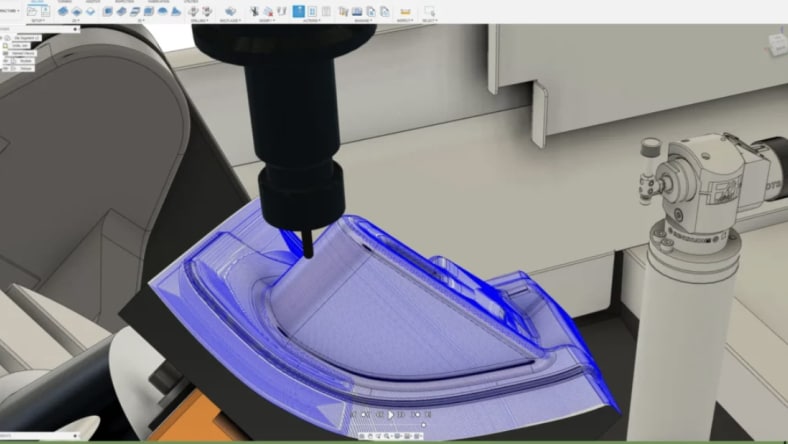

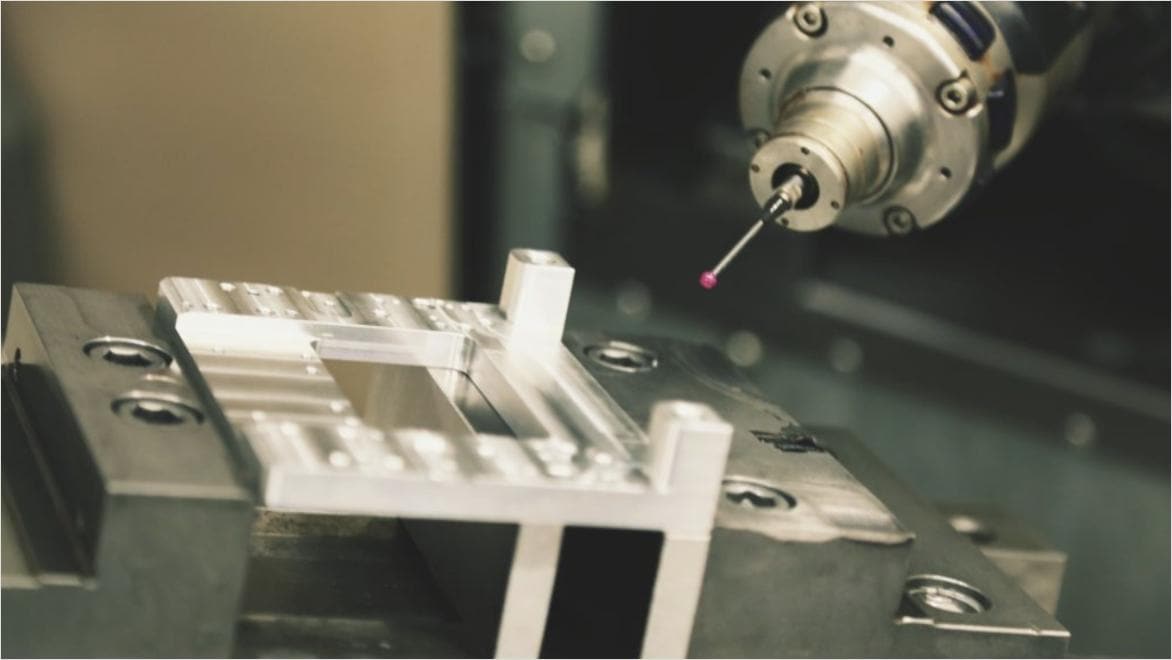

Preview tool movements on a digital twin of your machine to catch errors before cutting starts.

Optimize surface finish and cutting performance with intuitive tool axis controls using points, lines, or curves.

A clean, modern interface reduces the learning curve, making advanced machining easier for every skill level.

Autodesk Fusion for Manufacturing is a unified CAD/CAM platform that streamlines your workflow from design to final part. Whether you're making simple parts or complex geometries, Fusion lets you design, simulate, and machine—all in one place.

For 5-axis machining, Fusion supports both 3+2 and simultaneous strategies, helping reduce setups, improve finishes, and reach tricky features. With cloud-based tools, you can collaborate, simulate, and avoid costly errors before you even start cutting.

Program simultaneous and positional 5-axis strategies with easy access to swarf, morph, and contour toolpaths—all within an intuitive interface.

Modify your design and watch your toolpaths update automatically, ensuring tight alignment between part design and machining intent.

Simulate every move using a digital twin of your CNC machine to prevent crashes and costly errors—before you ever press start.

Fusion automatically detects and resolves potential tool collisions, protecting your machine, your part, and your timeline.

Whether you’re machining metal, printing composites, or fabricating sheet metal, Fusion adapts to your 5-axis needs across manufacturing workflows.

Access hundreds of pre-configured tool libraries and post processors for popular 5-axis machines from Haas, Mazak, Okuma, and more.

Our 5-axis machining solutions are trusted and enhanced by leading industry partners like Haas, Mazak, Okuma, Sandvik Coromant, Kennametal and many more.

CAMplete Solutions, based in Cambridge, Ontario, is revolutionizing 5-axis machining for Fusion users with simulation software tailored to specific CNC machines like Haas and Matsuura. Founded by University of Waterloo grads, CAMplete bridges the gap between Fusion CAM toolpaths and machine operations, helping machinists avoid costly errors and boost efficiency.

By solving common workflow challenges, CAMplete enables Fusion users to confidently produce complex parts with fewer mistakes and faster turnaround times.

As parts grow more complex and the push for customization accelerates, 5-axis machining has moved from advantage to necessity. The next wave of manufacturing is already here—driven by innovation and automation.

Emerging trends shaping the future:

AI-powered CAM programming

Digital twins and intelligent factories

Hybrid additive + subtractive machines

Lights-out machining with advanced automation

Fusion is at the forefront, evolving alongside these technologies to keep your shop smarter, faster, and ready for what’s next.

Learn what 5-axis machining is and how Autodesk Fusion, along with its extensions, can support your next project by providing advanced capabilities for creating complex geometries with precision.

5-axis machining moves tools along X, Y, Z, A, and B axes for faster, more precise cuts. Unlock complex designs and smoother finishes with advanced CAM software like Autodesk Fusion.

Unlock powerful, simplified 5-axis machining in Fusion. Learn when to use it, how to choose the right strategy, and optimize tool axis control with ease.

Take your 5-axis machining to the next level with Fusion. In Part 2 of this series, explore advanced tool axis control and powerful collision avoidance features that help you machine complex parts with precision and confidence.

Unlock advanced multi-axis machining, automated hole drilling, and smart nesting with the Fusion Manufacturing Extension—streamline programming and produce parts faster and better.

Learn how Fusion for Manufacturing can help to streamline workflows, reduce costs, improve product quality, and foster innovation.

5-axis machining moves the cutting tool or the workpiece simultaneously along five different axes—typically X, Y, Z (linear axes) plus two rotational axes (A and B). This allows the tool to approach the part from almost any direction, enabling the machining of highly complex geometries in a single setup.

In contrast, 3-axis machining moves the tool or part only along the X, Y, and Z axes, which limits the tool approach angle and often requires multiple setups to machine complex parts.

Improved accuracy: Fewer setups reduce errors caused by repositioning.

Shorter cycle times: Complex parts can be machined in one go, speeding production.

Better surface finish: The tool maintains optimal angles, reducing the need for manual polishing.

Ability to machine complex parts: Intricate shapes and undercuts that are impossible with 3-axis become feasible.

Longer tool life: Using shorter, more rigid tools reduces vibration and wear.

5-axis machining is ideal for parts with complex curves, multiple angled surfaces, or intricate details, such as:

Aerospace components like turbine blades and structural parts

Automotive molds and prototypes

Medical implants and surgical instruments

Precision molds and dies

Complex architectural models

These parts benefit from the flexibility and precision that 5-axis machining offers.

5-axis machining is a cutting-edge CNC technology that utilizes five axes of movement to create intricate parts and geometries, a process that traditional 3-axis machining cannot efficiently handle. Unlike traditional methods, which typically limit movement to three linear axes (X, Y, and Z), 5-axis machining adds two rotational axes, allowing the tool to approach the part from virtually any angle. This capability not only enhances accuracy but also significantly reduces setup times, as parts can be machined in a single setup, leading to higher efficiency and better overall quality

5-axis machining improves manufacturing efficiency by:

Reducing the number of setups needed, which decreases the time spent repositioning parts.

Enabling the use of shorter cutting tools that are more rigid and can cut faster with less vibration.

Allowing simultaneous multi-axis cutting, reducing overall cycle time.

Minimizing manual finishing steps by producing better surface finishes directly off the machine.

Lowering the risk of human error by automating complex tool movements.

Fusion for Manufacturing provides a comprehensive environment for programming, simulating, and managing 5-axis machining operations. Key features include:

Integrated CAM: Create and optimize 5-axis toolpaths directly in Fusion’s CAM workspace with adaptive and simultaneous multi-axis strategies.

Machine simulation: Visualize and verify 5-axis toolpaths in a virtual environment, helping detect collisions and errors before machining.

Post-processing: Fusion supports post-processors tailored for various 5-axis CNC machines, ensuring clean, machine-ready code.

Tool library management: Keep your tool data organized and accessible for efficient programming.

Collaboration tools: Share designs and manufacturing instructions with your team or external partners seamlessly.

The Fusion Manufacturing Extension is an add-on that brings advanced capabilities to your Fusion CAM workflow, specifically targeting complex machining tasks like 5-axis operations. It enhances productivity by offering:

Advanced simulation and verification: Realistic machine-specific simulation that identifies potential collisions, tool deflections, and other issues early in the process.

Intelligent toolpath optimization: Automatically adjusts strategies to reduce machining time without compromising quality.

Post-processor customization: Tailor NC code output to match the unique requirements of your 5-axis machines, improving reliability on the shop floor.

Machine kinematics support: Accurately simulates and accounts for your specific machine’s rotational axes and limits.

Enhanced workflow integration: Streamlines communication between CAD, CAM, and manufacturing execution, reducing errors and rework.

Yes, one of the standout features of the Manufacturing Extension is its machine-specific collision detection. It simulates the full 5-axis machining environment including the tool, holder, spindle, and machine components moving in real-time. This lets users:

Identify potential collisions and near-misses before running parts on the actual machine.

Verify complex movements involving rotational axes and unusual tool orientations.

Reduce costly machine crashes and material scrap.

Gain confidence in their toolpaths through detailed visualizations and analysis.

Yes, Fusion supports a wide range of 5-axis CNC machines through its flexible post-processing system. This means you can:

Generate NC code specifically tailored to your machine’s controller and kinematics.

Use ready-made post processors for popular machine brands like Haas, Mazak, DMG Mori, and more.

Customize post processors if needed to fit your shop’s unique requirements.

Ensure smooth communication between Fusion-generated toolpaths and your machine, reducing errors.

Quickly adapt to different machines without changing your entire programming workflow.

A: In 5-axis machining, the machine operates along five different axes simultaneously, which allows for more complex and precise shaping of parts compared to traditional 3-axis machining. Here’s how each axis works and why they’re important:

X, Y, and Z Axes: These are the primary linear axes and are common to most CNC machines.

Together, these three axes allow movement in a 3-dimensional plane. However, with only X, Y, and Z axes, the machine has limited access to the part’s surfaces, requiring multiple setups to complete complex shapes.

A and C Axes (Rotary Axes): The additional two axes in 5-axis machining provide rotational movement, allowing the cutting tool to approach the part from various angles without repositioning.

In some machines, the additional rotational axis is referred to as the B-axis rather than the A-axis, depending on the specific configuration. The combination of linear and rotary axes in 5-axis machining provides maximum flexibility, enabling complex, multi-sided machining in a single setup. This reduces setup time, enhances accuracy, and allows for intricate part geometries, which are especially valuable in industries like aerospace, automotive, and medical device manufacturing.

By utilizing these five axes, manufacturers can achieve greater precision and efficiency, delivering high-quality parts with complex shapes and tight tolerances.