& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

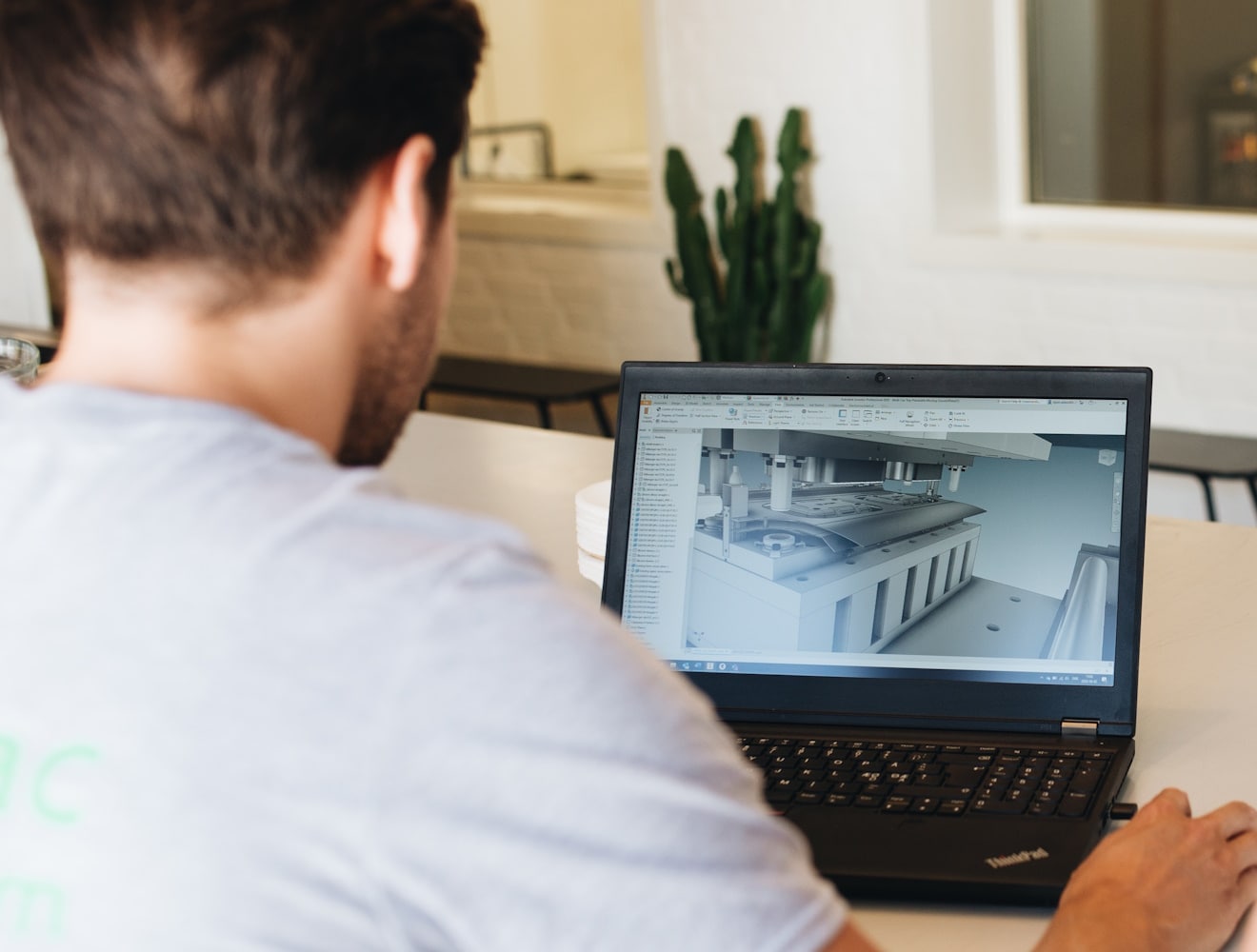

Professional CAD/CAM tools built on Inventor and AutoCAD

With 40 years of serving diverse markets with CAD, CAM, CAE, and PCB software solutions – Autodesk Fusion is a fully extensible cloud solution that covers all your manufacturing needs from quick design iterations to validation with simulation, all the way to manufacturing on your shop or factory floors.

Believe future growth will depend on digital tools

Plan to make technology investments over the next three years

Report that their company is “more digitally mature”

Autodesk, 2023 State of Design & Make report and study data

Increase your manufacturing throughput through automation, collaboration, and interoperability to reduce non-value-add processes.

Autodesk provides manufacturing software that helps optimize your manufacturing processes to increase productivity while reducing material costs, engineering costs, and fixed overhead costs.

"We use Autodesk Fusion to automate production and improve quality, meaning we can ship better quality products to our customers faster."

Phil Law, Pembree Ltd

Siloed working practices are a thing of the past. Bring together data, teams, functions, and departments to create the best products possible.

Autodesk advanced manufacturing software connects your design, engineering, and manufacturing teams using a single tool to ensure performance, end-user requirements, and manufacturability are all met.

"Our business has grown by 400% in just over a year. We can attribute a lot of this growth to Fusion 360"

Konrad Nerc, Nerc Precision Engineering Ltd.

Easily iterate, prototype, and simulate with automated, connected workflows that can improve product performance throughout your product development cycle.

Autodesk manufacturing software utilizes automation, simulation, data management, and quality management to help you reduce costly non-conformities and defects.

"Fusion 360 has reduced our non-conformance reporting by 34% and helped us double our shop revenue."

Paul Bourne, Brown & Holmes (Tamworth) Ltd.

Empowering people to design, collaborate, build, and fabricate in ways that improve productivity–while also reducing waste, saving money, and staying competitive–is the goal behind our sustainable design technology.

Autodesk software harnesses the power of automation to achieve business and sustainability goals.

"The advanced nesting capabilities in Fusion 360 have helped us reduce our scrap rates from 25% to under 5%."

Richard Ganas, Ganas Manufacturing

Customers all over the world use Autodesk Fusion to connect with their teams, grow their businesses, and continue to make anything.

Making Aircraft Lighter

Aerospace giant uses generative design and additive manufacturing to create large airplane cabin parts using 95% less material.

Making prototypes faster

Specialist prototyping shop uses integrated design and manufacturing software to automate machining and shorten project delivery times.

Making bikes more sustainable

Mountain bike component manufacturer uses advanced 5-axis CNC machining to produce quality parts that don't cost the Earth.

Making molds more accurately

Mold manufacturer streamlines the production of molds, tools, dies, and electrodes with automated and integrated CAD/CAM software.

Making furniture with less waste

Furniture maker uses cloud-based collaboration and automated nesting to improve consistency and reduce scrap rates to 5%.

Making coral grow and thrive

Global team partners to scale coral reef restoration, giving marine life a new place to call home for generations to come.

Autodesk Fusion connects capabilities, data, and people across the entire product development lifecycle.

Autodesk Fusion connects your entire manufacturing process by integrating CAD, CAM, CAE, and PCB into a single solution allowing you to design and make anything.

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

Optimize part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection molding, and more.

Build on Autodesk Fusion by accessing additional capabilities in the extended family of Fusion products.

We've teamed up with leading hardware, software, and tooling companies to leverage partner technologies. Learn more about Autodesk partnerships.

A safe space for you to explore the emerging technologies that are changing the world of manufacturing.

Behind the scenes at the Autodesk Technology Center, Birmingham UK (video: 1:48 min)

With ongoing pressures to make parts today and meet your customers’ deadlines, we recognize it’s difficult to test, learn, and implement new manufacturing processes.

Our global network of technology centers help you expand your R&D capabilities to drive manufacturing innovation, using Autodesk advanced manufacturing software to push the limits of the latest hardware available today.

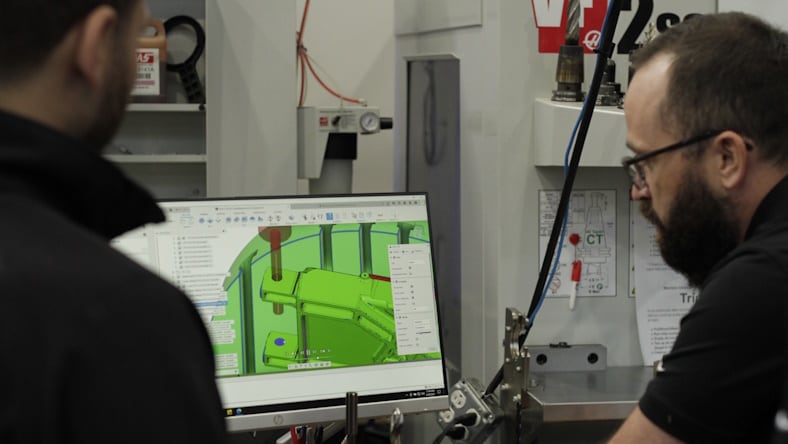

Powerful modeling tools simplify the preparation of 3D models, jigs, fixtures, electrodes, and more in readiness for manufacture.

Automate the creation of high-quality 2.5D, 3-, 4-, and 5-axis machine code with professional-grade tools to make better use of your CNC machines.

Create optimized and associative multi-sheet layouts for metal and non-sheet metal components for laser, waterjet, plasma, or CNC routing.

Streamline the preparation, programming, and production of parts with 3D printing using a variety of materials and manufacturing processes.

Access specialist programming and simulation tools to produce small, accurate parts using synchronous cutting on Swiss and multi-axis lathes.

Flexible, easy-to-use tools for the offline programming of robots help you optimize robotic paths for manufacturing cells and systems.

Optimize your shop-floor production with real-time insights to help schedule and manage your teams, machines, and materials.

Improve the quality and consistency of your manufacturing facility using offline programming tools to drive inspection hardware and processes.

Connect your teams and suppliers to the data and insights needed to make business-critical decisions faster and shorten delivery times.

Autodesk Fusion provides all the essential tools you need for 2D, 3+2, CAM, and 3D printing, as well as cloud collaboration tools. For more advanced CNC machining, Autodesk Fusion subscribers can upgrade to include the Autodesk Fusion Machining Extension. This extension unlocks additional, advanced capabilities to make better use of 3-axis and multi-axis CNC machinery, including automated programming, multi-axis milling, and more.

Autodesk provides a range of manufacturing software products. The best option will vary based on your specific needs. In the vast majority of cases, Autodesk Fusion. It offers the tools you need for 2D and 3D CAD (design), 2.5D to 5-axis CAM (manufacturing), as well as additive manufacturing (3D printing), metrology (inspection), simulation (CAE), and much more.

For the most complicated applications, Autodesk provides a suite of specialist products that can be used alongside Autodesk Fusion to access more advanced tools. These products include:

Autodesk Fusion is the fastest-growing CAD/CAM software available today. As a professional-grade software tool, Autodesk Fusion offers powerful programming tools for 2D, 2.5D, 3-, 4-, and 5-axis milling on a growing range of CNC machine types and NC controllers. What makes Autodesk Fusion different is how it puts your data at the center of everything you do, allowing your team and your stakeholders to work together seamlessly.

Get an in-depth look at the advanced CAM capabilities in Autodesk Fusion here.

A subscription to Autodesk Fusionprovides access to the core CAD/CAM/CAE tools. You can also choose to add one or more Autodesk Fusion Extensions to your subscription to unlock more advanced capabilities for an additional fee. Choose from extensions for CNC Machining, Nestig & Fabrication, Additive Manufacturing, Data Management, Simulation, and more.

A subscription to the specialty products PowerMill, FeatureCAM, PowerInspect, PowerShape, CAMplete, and Netfabb also includes a subscription to Autodesk Fusion. In most cases, these also include one or more Autodesk Fusion Extensions. To learn more about what's included in each of the products listed here, use the links to visit the respective product centers.

Call 1-833-843-3437 to speak with an approved Autodesk representative about your specific manufacturing needs.

Don't worry. Getting up and running with Autodesk Fusion is really easy. As soon as you subscribe, you'll receive a series of emails that guide you through the process of installing and using Autodesk Fusion. For now, check out these handy links to see for yourself.

Our network of approved Autodesk Fusion resellers is also available to help with additional training, post-processor support, and more.

Autodesk has long-standing relationships with most of the world's biggest suppliers of CNC machinery for additive and subtractive manufacturing. In many cases, this means we can provide accurate 3D models of the machine, as supplied by the company that made it. In addition, we have a growing library of tried-and-tested post-processor option files that can be used to generate G-code files to run your specific machine. Use the following links to download the latest CNC machines and post-processor files for use in Autodesk Fusion completely FREE.

If you're using products like PowerMill, FeatureCAM, or PowerInspect, you can also access a vast library of FREE 3D machine models and post-processors. Simply contact your local Autodesk reseller to find out more.