& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Bicycle parts manufacturing is an industry where exacting customer desires and high-tech fabrication methods and materials converge to achieve results that continue to defy expectations.

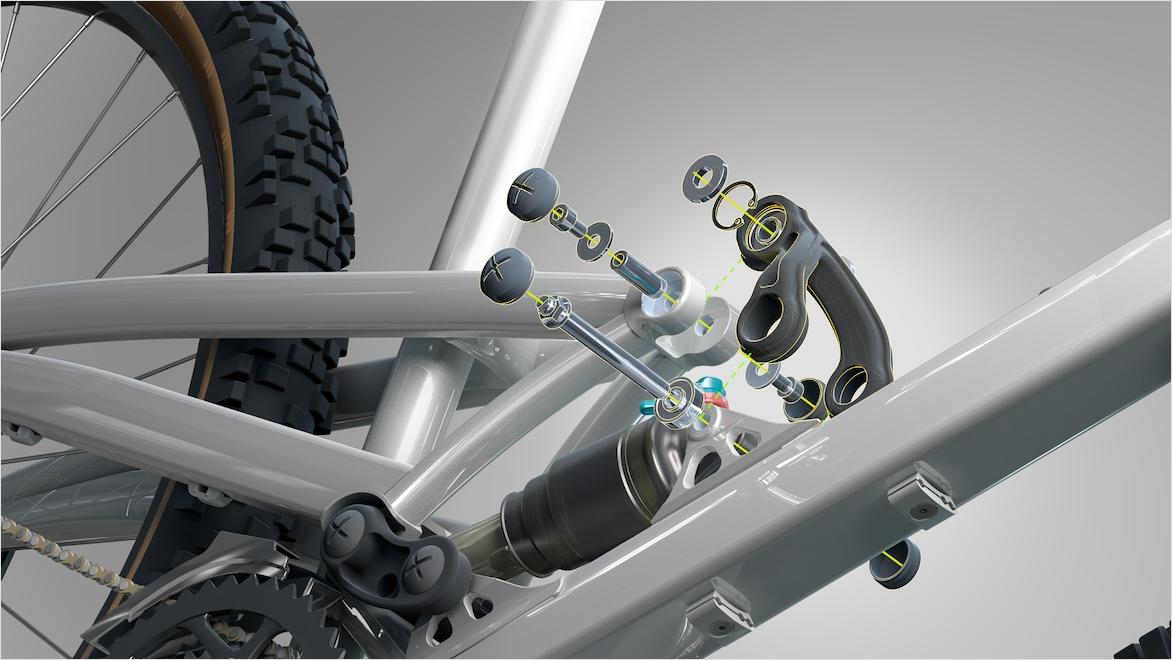

With the combination of advanced software features like generative design, fabrication tools like CNC machines and 3D printers, and materials like titanium alloys for metal additive manufacturing, companies that design bike accessories and parts delight their customers with higher standards of performance and sustainability.

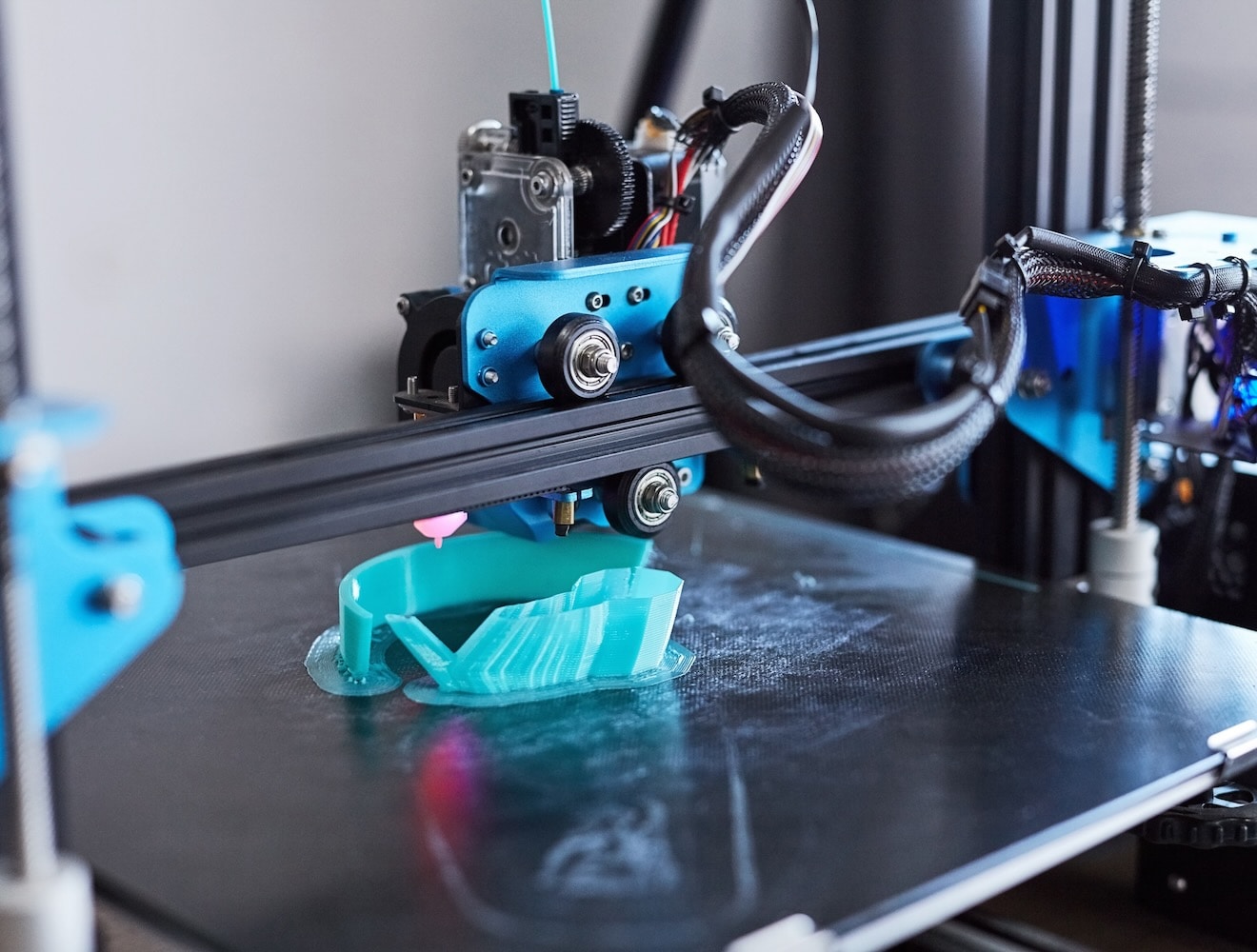

There’s never been a better time to be a cycling enthusiast, because bicycle parts manufacturers have never had a better set of advanced hardware and software tools at their disposal for crafting customer-focused, high-performance, and sometimes bespoke bike accessories and components. Both additive manufacturing (3D printing) and CNC machining manufacture bicycle components of complex geometries with tight dimensional tolerances. More tried-and-true bike parts manufacturing methods, like plastic injection molding and sheet metal fabrication, are still extremely relevant, often for high-volume production.

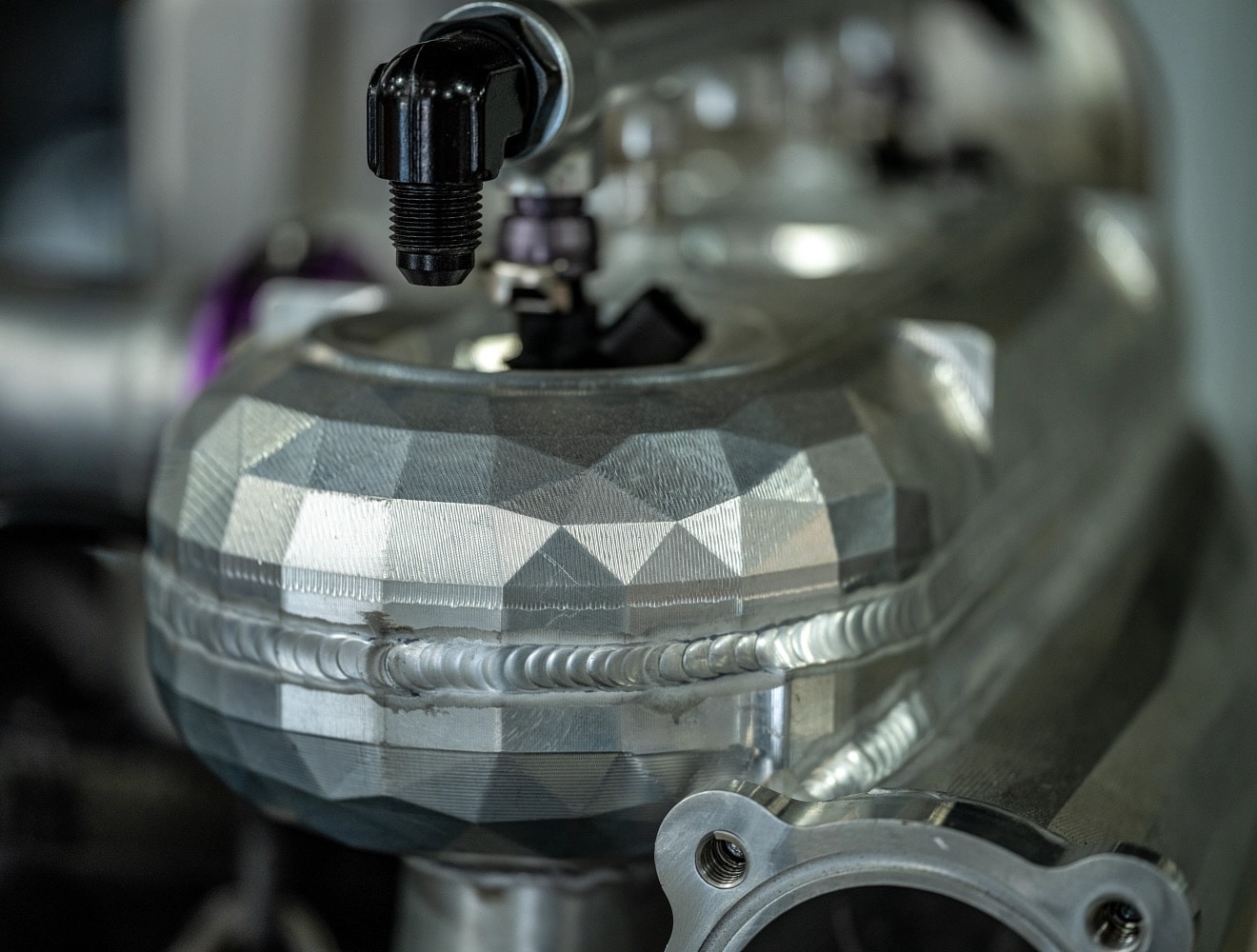

With additive manufacturing techniques like 3D printing, bike parts designers can fabricate parts from generative design software like Autodesk Fusion, which otherwise could not be made easily or at all. Generative design, along with metal additive manufacturing, has helped bicycle parts manufacturers do more with less—for example, making a titanium crankarm that is twice as strong but also 20% lighter.

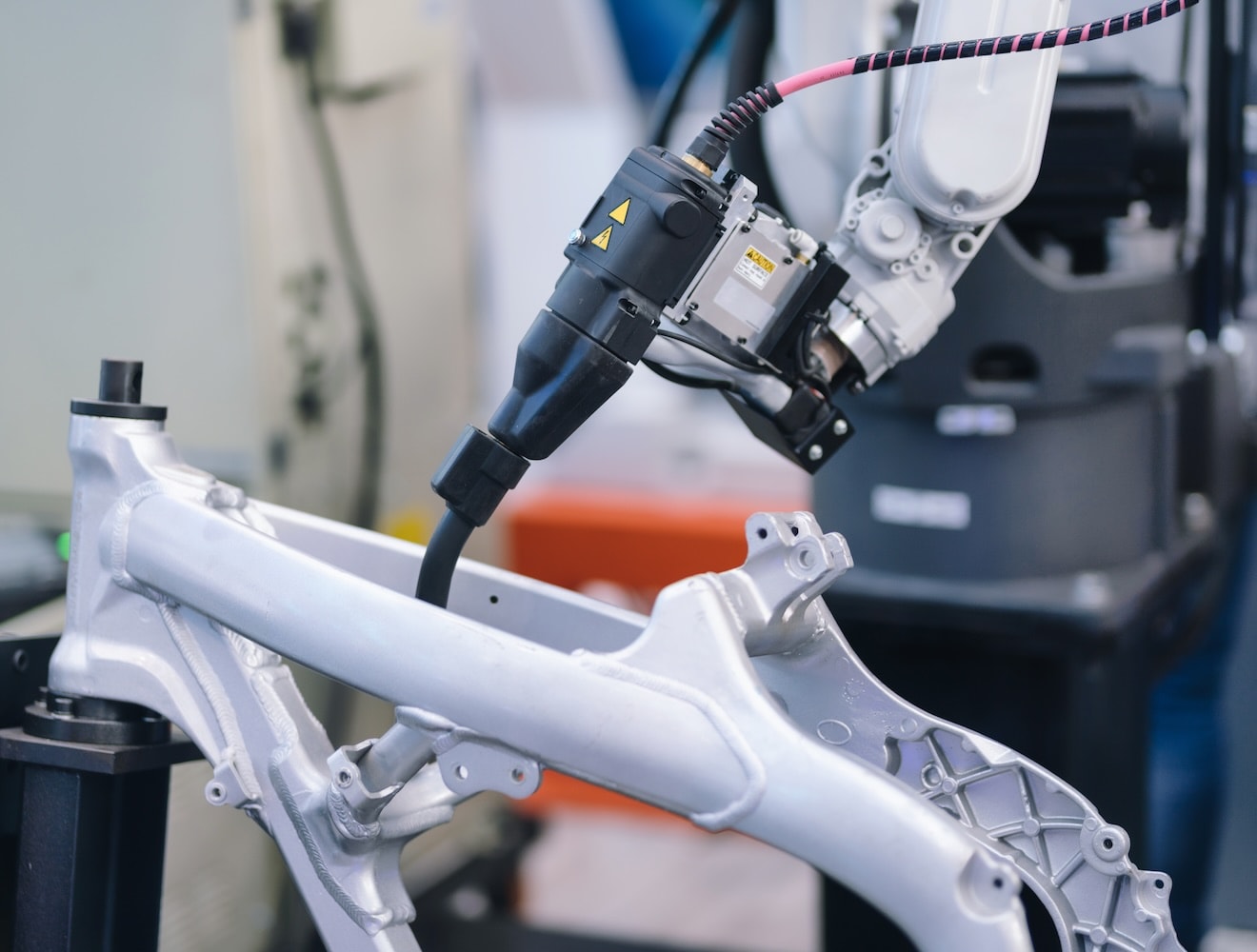

Precision CNC machining from robot-loaded, 5-axis machines can also manufacture bicycle parts of intricate geometry from premium materials like aerospace-grade aluminum alloy. Both CNC machining and 3D printing work well for prototyping, custom manufacturing of bespoke parts, and small production runs of bicycle parts.

Regardless of the method or production volume of bicycle parts manufacturing, integrated design and manufacturing software like Fusion helps automate processes, optimize workflows, and find other efficiencies. Uniting computer-aided design (CAD), computer-aided manufacturing (CAM), and computer-aided engineering (CAE) all in one cloud-connected platform, Fusion includes tools and features specifically for designing and manufacturing with sheet metal and for simulating the results of plastic injection molding.

Fusion’s generative design features make it easy for designers to optimize the performance parameters for bike accessories design so that there’s no compromise in the final results. CAM features like Part Alignment have also saved bicycle parts manufacturers money by allowing them to create their own fixtures rather than outsourcing them.

Following any method of bicycle parts manufacturing, post-processing may be needed to finish the parts. Part-processing capabilities include anodizing, powder coating, heat treatment, and other processes. Fusion includes helpful post-processing files that convert generic toolpath information into code for specific machines and machine controllers.

Incorporating advanced CAD and CAM software into bicycle parts manufacturing and design results in valuable benefits across the board, including:

With both CAD and CAM in one software, Autodesk Fusion facilitates accuracy in design and precise fabrication of intricate bike parts and components from a diverse selection of compatible materials. CAM features include automatic toolpaths and automatic data translation.

Make efficient use of the resources of time, money, and materials. Bicycle parts manufacturing with CAD/CAM software and CNC machines can reduce material usage from human error and physical prototyping needs, as well as help streamline workflows to save time and cost.

Autodesk Fusion lets you standardize CAM programming across your team, reduce programming times, and make CNC programming results more consistent—all contributing to faster bike parts manufacturing and making the custom manufacturing of bespoke parts more efficient.

Autodesk software like Fusion incorporates part inspection features, including intelligent part alignment, superior strategies for machining surfaces, advanced tool axis controls, and quality control processes—all leading to higher-quality outcomes.

Cloud-connected bicycle parts manufacturing and design software from Autodesk allows real-time communication with collaborators anywhere in the world, as well as a single source of data updated in real time. This contributes to more informed decision making and a smoother collaborative workflow.

The Fusion Simulation Extension includes generative design for optimizing bike parts’ designs for strength, weight, and other constraints, as well as simulations like finite element analysis (FEA) for virtually testing the parts’ responses to real-world stresses and forces.

Optimize part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection molding, and more.

Computational fluid dynamics simulation and solid body motion analysis software. Available as CFD Premium and CFD Ultimate

PEMBREE

A cycling-based passion project became a sustainable bike parts manufacturing business when Phil Law founded PEMBREE with a handful of CNC machines and Autodesk Fusion. The carbon-neutral micro-factory cranks out hundreds of bicycle pedals a month with recyclable aerospace-grade aluminum alloy, using only renewable energy.

Image courtesy of PEMBREE Ltd

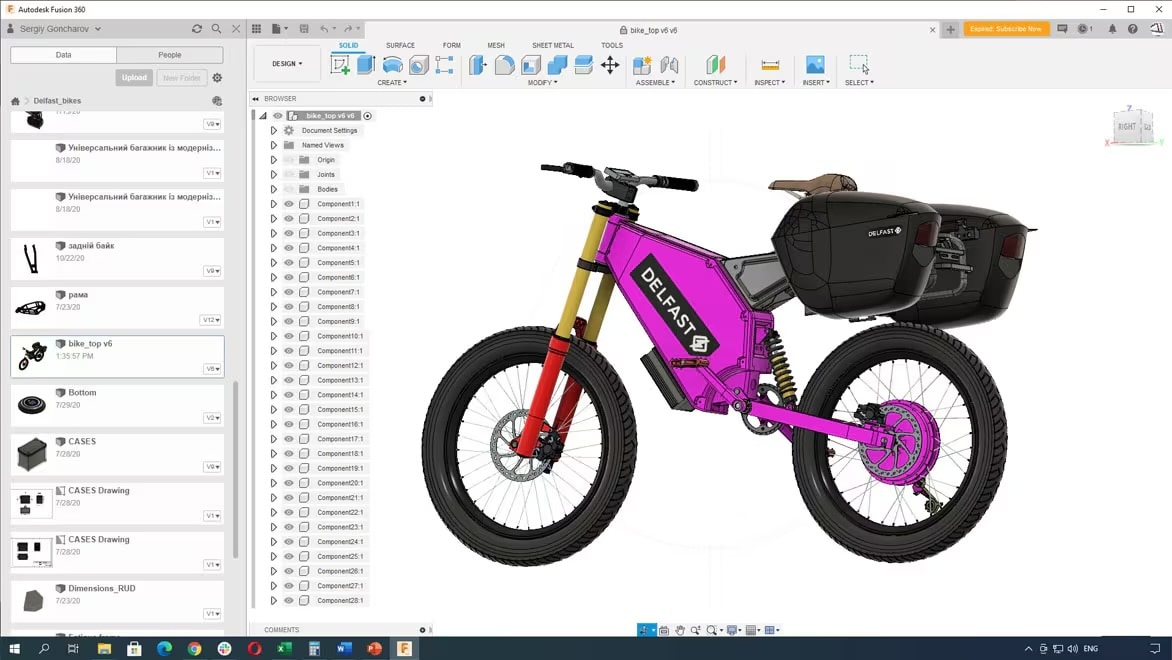

DELFAST

When available electric bicycles did not live up to the needs of its local delivery service, the Kyiv company Delfast decided to build a better e-bike. It started by manufacturing bicycle parts like a stronger frame using Autodesk Fusion, then moved on to entire bicycles, relying on Fusion’s simulation tests to all but give up physical prototyping.

Image courtesy of Delfast

SRAM

The bicycle parts manufacturer SRAM wanted to innovate on one of the most stagnant but important parts of a bicycle: the crank arm. SRAM turned to additive manufacturing and Autodesk Fusion’s generative design abilities to experiment. The resulting titanium crank arm was twice as strong as previous models, but 20% lighter, meaning the cyclist spends less energy to pedal.

See how Mike Burrows and Barney Townsend attempted to design the fastest bicycle in the world, turning to Autodesk CFD for aerodynamics analysis and Fusion for generative design of lightweight and optimized bicycle parts manufacturing.

Precision machining employs the subtractive manufacturing processes of CNC machines to craft complex parts with the tightest of tolerances. Learn more, including how Autodesk software sets up and ensures the best results for precision-machined bicycle parts.

Find out how Predator Cycling, a custom carbon fiber bicycle and bicycle parts manufacturer, entered the world of generative design using Fusion to rapidly alter design ideas and easily modify changes based on individual customer requirements.

Learn all about post-processor files and why and where to get them for Autodesk Fusion. During bicycle parts manufacturing, post processors may be needed to convert generic toolpath information into code that specific CNC machines can understand.

French sporting goods company Decathlon wanted to give each of its customers the experience of a professional cyclist, including a bicycle and bike accessories designed just for them. To achieve that, they relied on Autodesk Fusion’s generative design to optimize certain bike parts’ designs and to 3D print them with recyclable aluminum.

User-centered bike parts design can often benefit from custom manufacturing, the highly configurable and flexible manufacturing methods that allow bespoke, built-to-order parts while keeping costs and production times in line.

The manufacturing process of a bicycle begins with bike parts design in CAD modeling software, including materials selection. Next, the bicycle frame is usually produced from welded cut metal tubes or molded carbon fiber. Then, the remaining bicycle parts are manufactured, often requiring precision CNC machining and finishing.

Next comes assembly of the manufactured parts, followed by quality control and testing. If the customer has ordered custom touches like colors, finishes, or specific custom components, that has to be taken care of before the final steps of packaging and shipping.

The most common raw materials used in bicycle manufacturing and bicycle parts manufacturing are:

Other materials popular for bike parts and bike accessories design include rubber, plastics, fabrics, and other composites.

Modern bike design requires a refined approach that combines engineering and materials science with user-centered design. Key requirements include the bike frame’s geometry, material selection, weight optimization (which can benefit from generative design software), aerodynamics (which can benefit from computational fluid dynamics software), ergonomics, safety, sustainability, the efficiency of the bicycle parts manufacturing process, and, if offering customization, the processes of custom manufacturing.

Technology affects every stage of modern bicycle manufacturing. Designers use software from the initial product sketching stage to CAD design and 3D visualization, and AI-assisted generative design can reveal otherwise unattainable efficiencies. Software simulation and testing are also highly accurate and save physical testing resources.

At the production stage, CNC machining and 3D printing, or additive manufacturing, make prototyping, custom manufacturing, and small-batch manufacturing more accessible and efficient, while robotic automation makes bicycle manufacturing at scale more consistent, safe, and efficient.

Cloud and AI technology even help with making bicycle manufacturing more sustainable by analyzing data for opportunities to reduce waste or to make the supply chain more environmentally friendly.

Manufacturing processes can be optimized for efficiency in a variety of ways. Linking design with manufacturing and operations by using software that combines CAD, CAM, and product lifecycle management (PLM) in one cloud platform improves efficiency, communication, and scalability. Automating manufacturing processes through robotics and/or CNC machining promotes better efficiency. And if those machines collect real-time performance data, analyzing that data can yield insights for fixing bottlenecks, predictive maintenance, supply chain optimization, improving quality control, and more.

The above initiatives may also require ongoing employee training and reskilling, which should also pay off in efficiency.