& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

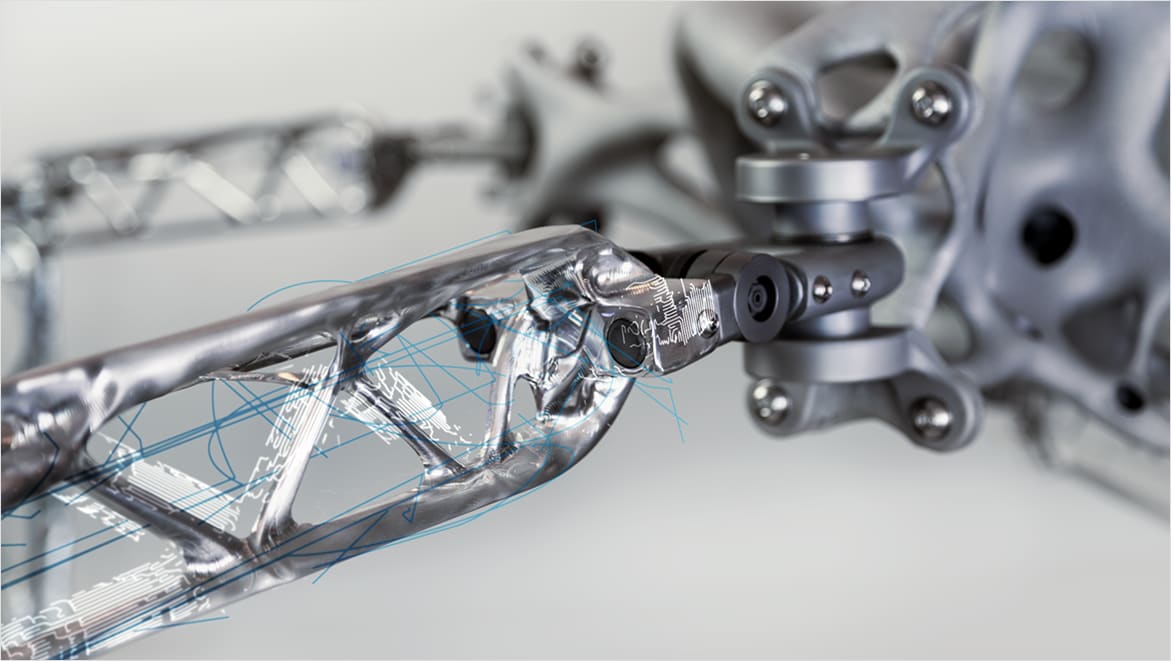

Generative design uses algorithms to create multiple solutions based on your specified goals and constraints. Instead of manually sketching and revising, designers can automatically explore a wide range of smart, optimized options. This approach doesn't replace human creativity—it expands possibilities and inspiration for designers.

AI is the core engine behind generative design. By running simulations, testing variables, and learning from outcomes, AI can produce hundreds of design variations in a fraction of the time. This enables designers to identify what works, detect patterns, and select the best-performing option. Think of AI as a creative partner that manages the heavy lifting, allowing designers to focus on vision and decision-making.

Generative design outshines traditional design methods with its speed, efficiency, and innovation. Instead of slow trial and error, designers receive data-driven insights and ready-to-use concepts. The outcomes are often lighter, stronger, and more sustainable, pushing creativity further while conserving time and resources. In essence, generative design melds the power of AI with human insight to deliver superior results compared to traditional approaches alone.

Design AI improves design processes and outcomes using machine learning. It aids in data analysis, pattern recognition, and generating innovative solutions, helping designers with tasks like concept generation and automating repetitive processes.

Design AI enables collaboration between human designers and intelligent systems. AI enhances human creativity with data-driven suggestions to expand design possibilities and improve decision-making; yielding more efficient workflows and higher-quality output.

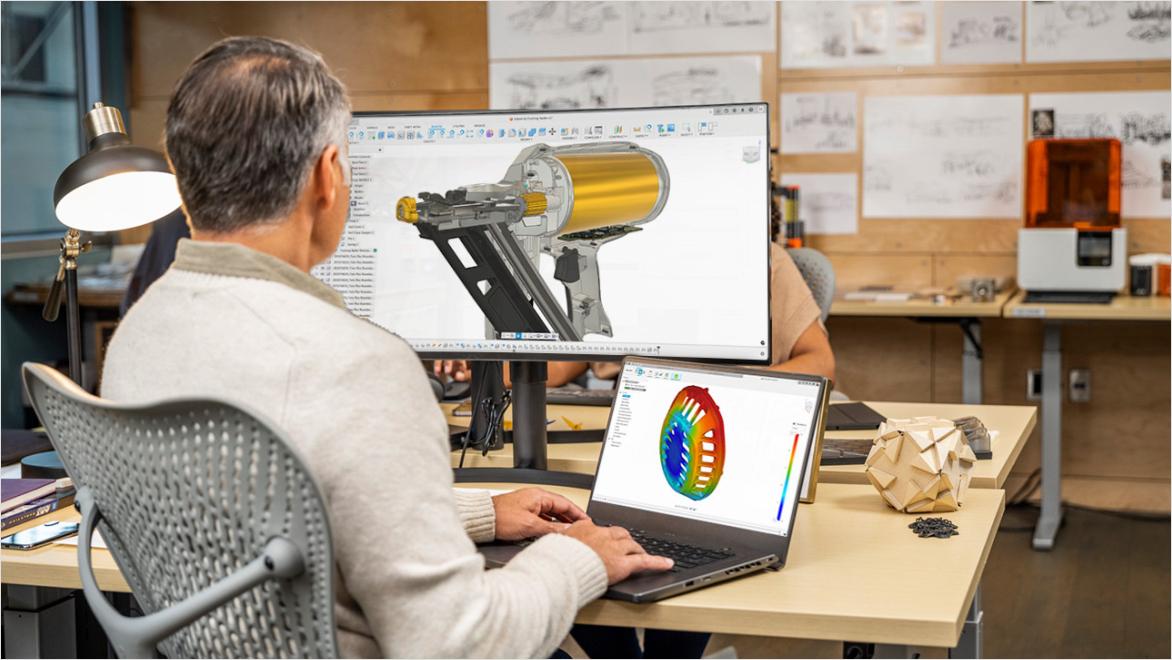

Autodesk leads in generative design by blending powerful AI with user-friendly design tools. Platforms like Fusion, Autodesk's industry cloud for manufacturing empower designers and engineers to create smarter, optimized solutions without complicating workflows.

AI-driven design Fusion centralizes generative design with modeling, simulation, and manufacturing in one platform. Use AI-driven features in everyday workflows, defining goals like weight reduction, strength, or cost efficiency. AI generative design then provides multiple design options for the quick exploration of different directions while keeping project goals in focus.

Engineers can also test stress, load, and material performance during design generation, minimizing the need for costly physical prototypes. This results in faster iterations, fewer errors, and ready-for-market designs.

Powerful design, simulation, and lifecycle management tools for engineers, designers, and teams working on complex, high-performing designs.

Go beyond CAD with advanced design tools:

Try Autodesk Fusion free for 30-days

Improve product performance in Fusion with access to advanced simulation capabilities including structural, thermal, explicit, and injection molding manufacturability.

For existing Fusion subscribers looking for advanced capabilities:

Autodesk Fusion for Design combines the core capabilities contained in a subscription to Autodesk Fusion with the professional-grade tools contained in the Fusion Design Extension, the Fusion Simulation Extension, and the Fusion Manage Extension, and at a more competitive price than purchasing each individually.

Access advanced 3D design and modeling tools, including generative design and design AI, that automate processes and are manufacturing-aware. Manage design changes with pre-built workflows and validate design performance and manufacturability using integrated simulation.

Generative design AI empowers engineers and designers to achieve more with less. By rapidly generating thousands of design alternatives, it helps reduce material costs, accelerate product development, and support sustainable choices—all while unlocking innovative solutions that traditional methods often overlook.

Explore a vast number of design possibilities and generate innovative solutions that may not have been considered by human designers.

Generative design AI can optimize designs based on given constraints and objectives. It can consider factors like material usage, structural integrity, cost, and performance to generate designs that are efficient and optimized for specific requirements.

Speed up the design process by automating the generation and evaluation of design options. It can quickly iterate through numerous design variations, allowing you to explore a wide range of possibilities in a shorter amount of time.

Generative design AI provides a common platform for exploring and evaluating design options, enabling better communication and decision-making. It also helps bridge the gap between different disciplines and expertise, leading to more holistic and integrated designs.

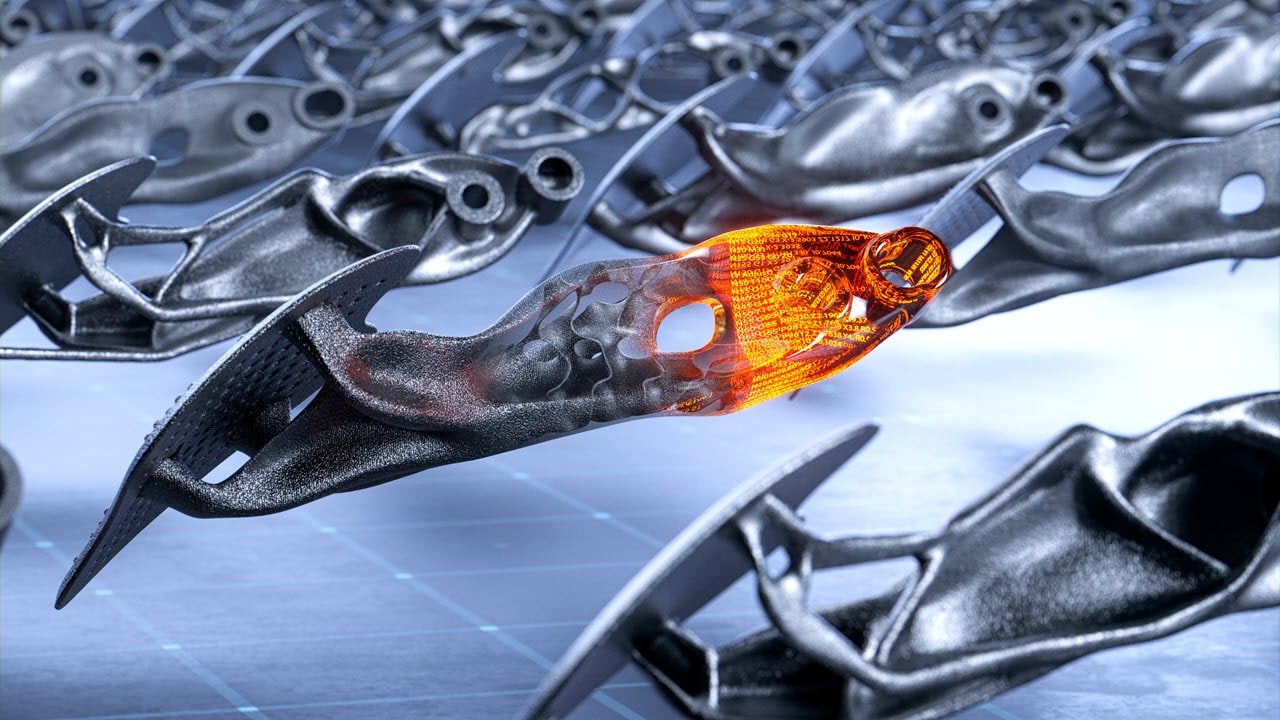

Explore multiple manufacturing-ready outcomes that meet design specifications, reduce weight, improve performance, and consolidate parts using generative design.

Identify design requirements, constraints, materials, and manufacturing options to generate manufacturing-ready designs.

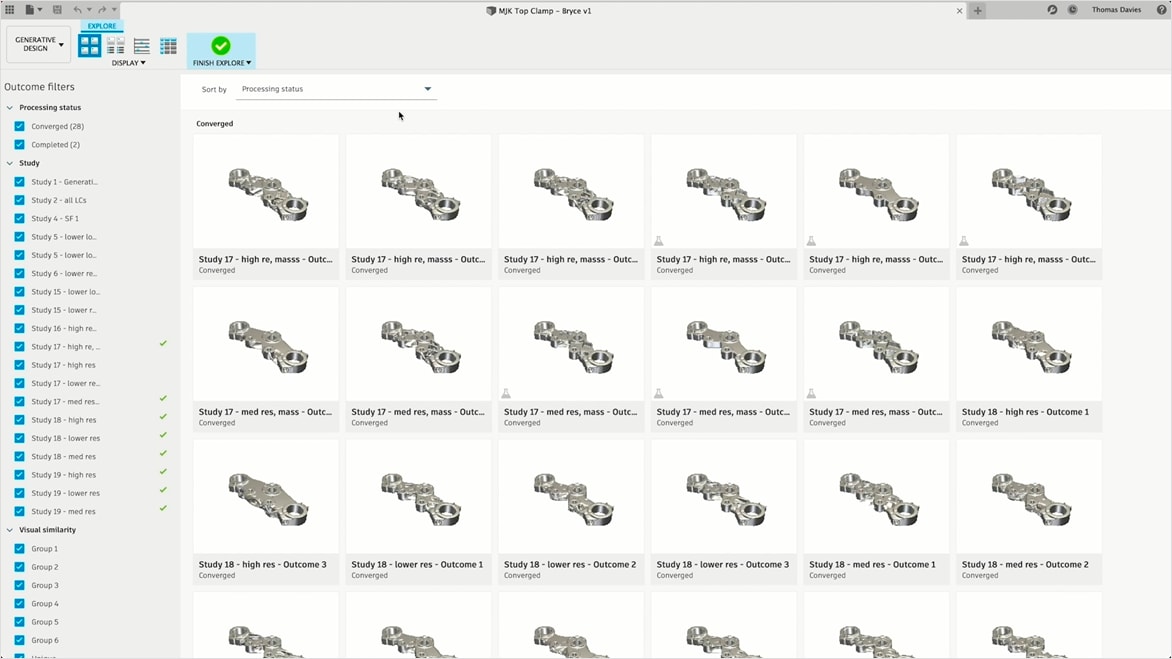

Review cloud-generated design outcomes based on visual similarities, plots, and filters powered by machine learning.

Avoid lengthy import-export processes by choosing outcomes and immediately editing them in your modeling environment.

Simultaneously solve various design outcomes, allowing you to focus on other tasks by offloading complex calculations to the cloud.

Make informed decisions balancing performance and cost early in the design process by estimating the impact of production volume on manufacturing costs based on generated design outcomes.

Autodesk AI streamlines design and manufacturing by automatically constraining sketches, automating drawing creation, and accelerating CNC toolpath programming—saving time, reducing errors, and enabling teams to focus on innovation.

Autodesk AI analyzes design sketches to automatically identify and maintain the ideal relationships, ensuring your sketches are always fully constrained.

This saves you time and effort, allowing you to focus on the enjoyable and productive aspects of design.

Speed up drawing creation by recognizing and removing purchased components, generating dimensioning strategies, and reducing manual work.

Enable your team to focus on innovation and refinement by minimizing errors, accelerating time-to-production, ensuring consistency, and enhancing productivity.

Our partnership with CloudNC reduces toolpath programming times in Fusion by up to 95%.

This year, we've integrated natural language AI prompts in Autodesk Assistant with CNC machining, making part cutting even easier. Transition smoothly from design to manufacturing with enhanced efficiency and convenience.

NEWTON ENGINEERING

Newton | Engineering and Product Development are supporting the Mars Sample Return with a lid designed using generative design in Fusion.

Image courtesy of Newton | Engineering and Product Development

STEWART-HAAS RACING

Stewart-Haas Racing is a championship-winning NASCAR organization. Learn how the team was able to lightweight a brake pedal using generative design in Autodesk Fusion.

Image courtesy of Stewart-Haas Racing

SRAM

Bicycle component manufacturer, SRAM, used additive manufacturing, and generative design in Autodesk Fusion to create a new type of bicycle crankarm.

Image courtesy of SRAM

Generative design AI is widely used in manufacturing and product design to optimize the design of components and products. It can generate designs that are lightweight, structurally sound, and cost-effective.

Generative design AI is used to optimize building designs, improve structural integrity, and enhance energy efficiency. It can generate design options that consider factors like material usage, building performance, and environmental impact.

Generative design AI helps optimize vehicles and aircraft. It generates designs that are aerodynamically efficient, lightweight, and structurally robust. Thus helping improve fuel efficiency, reducing emissions, and enhancing overall performance in these industries.

Generative design AI differs significantly from Generative AI used for creating images or text. While the latter focuses on producing visual or written content based on vast datasets and learned patterns, Generative design AI, like that found in Autodesk Fusion is geared towards creating practical, functional design solutions. It uses engineering principles and constraints to generate optimized, performance-driven designs that meet specific requirements such as strength, weight, or material efficiency.

Generative design AI is tailored specifically for engineers and designers. Unlike other AI tools that might produce aesthetic or creative outputs, this AI aims to solve real-world engineering problems. This purpose-built nature ensures that the generated designs are not only innovative but also manufacturable and performance-oriented, directly addressing the practical needs of the design and manufacturing industry.

The integration of AI in design and manufacturing has evolved from basic automation tools to sophisticated systems that enhance creativity, efficiency, and productivity. As AI continues to advance, it promises to further revolutionize the way products are designed and manufactured, paving the way for more innovative and efficient processes.

Early beginnings

In the 1950s and 1960s, the concept of artificial intelligence (AI) was first introduced, with early research focusing on problem-solving and symbolic reasoning, laying the groundwork for future applications in various fields, including design and manufacturing.

In the 1970s, the development of computer-aided design (CAD) systems began, allowing designers to create detailed 2D and 3D models, which, although not AI-driven, represented a significant step towards automating the design process.

Rise of Expert systems

In the 1980s, expert systems, which mimic the decision-making ability of human experts, gained traction and were used to optimize production schedules and diagnose system faults in manufacturing processes.

In the 1990s, AI began to integrate into CAD systems, providing tools for design optimization and error detection, and AI-driven simulations were used to test product performance under various conditions.

Machine learning and optimization

In the 2000s, sophisticated machine learning algorithms enabled predictive maintenance and real-time monitoring in manufacturing, using AI to analyze data, predict equipment failures, and optimize production processes.

In the 2010s, generative design emerged, using AI to explore and optimize design possibilities, and the rise of additive manufacturing (3D printing) leveraged AI for design optimization and process control.

Modern era

In the 2020s, AI became deeply integrated into design and manufacturing with advanced tools offering automated design generation, real-time collaboration, and predictive analytics, enhanced by cloud computing.

AI-driven systems currently enable end-to-end automation from design to production, utilizing natural language processing (NLP) and computer vision to streamline workflows and improve accuracy, with partnerships like Autodesk and CloudNC significantly reducing toolpath programming times and simplifying CNC machining.

The future of AI in design and manufacturing holds immense potential. As generative design AI continues to evolve, it promises to further enhance the capabilities of engineers and designers, enabling the creation of even more efficient, sustainable, and innovative products. Future advancements may involve more intuitive interfaces, real-time feedback, and greater integration with manufacturing technologies like 3D printing and CNC machining. This evolution will drive the industry towards smarter production processes, reduced material waste, and optimized performance, marking a significant leap forward in how products are designed and manufactured.

Get ahead of the curve and gain access to more design alternatives and faster production with generative design in Autodesk Fusion.

Generative design in Autodesk Fusion is a tool powered by AI that is shaping the future of manufacturing, one unique outcome at a time.

These videos and step-by-step guides will help you set up and create generative designs in Autodesk Fusion.

Generative design AI typically involves inputting design goals and constraints into an AI system, which then generates multiple design options that meet those requirements. The AI system can iterate through numerous design variations, considering factors like material usage, structural integrity, cost, and performance, to generate innovative and optimized designs.

Generative design and generative AI are related concepts but have distinct differences:

Generative design is a specific application of AI that focuses on using AI algorithms to generate and optimize designs. AI is a broader field that encompasses the development of intelligent systems capable of performing a wide range of tasks.

Yes, Autodesk Fusion 360, a popular 3D CAD, CAM, and CAE software, includes generative design functionality. Autodesk has integrated generative design capabilities into Fusion 360 to enable designers and engineers to explore and optimize design options using AI algorithms.

With generative design in Fusion 360, users can define design goals and constraints, such as material usage, manufacturing limitations, and performance requirements. The software then uses AI algorithms to generate multiple design options that meet those criteria. These generated designs can be further refined and evaluated by the user to select the most suitable solution.

Generative design AI has several applications in the manufacturing industry. Here are a few examples:

Optimal Part Design: Generative design AI can be used to optimize the design of individual parts or components. By entering design goals and constraints, such as weight reduction, structural integrity, and manufacturing limitations, generative design AI algorithms can generate multiple design options that meet those criteria. This helps manufacturers create lightweight, efficient, and cost-effective parts.

Assembly and Manufacturing Process Optimization: Generative design AI can optimize the assembly and manufacturing processes. By considering factors such as material usage, tooling requirements, and production constraints, generative design AI algorithms can generate optimized assembly sequences and manufacturing workflows. This can lead to improved efficiency, reduced costs, and enhanced quality in the manufacturing process.

Product Customization: Generative design AI can assist in product customization by generating design variations tailored to specific customer requirements. By entering customer preferences and constraints, generative design AI algorithms can generate personalized product designs that meet those specifications. This enables manufacturers to offer customized products without sacrificing efficiency or cost-effectiveness.

Material Selection and Optimization: Generative design AI can help in selecting and optimizing materials for manufacturing. By considering material properties, performance requirements, and cost factors, generative design AI algorithms can suggest optimal material choices for specific applications. This helps manufacturers make informed decisions about material selection, leading to improved product performance and cost-efficiency.

Design for Additive Manufacturing (3D Printing): Generative design AI is useful in designing for additive manufacturing processes like 3D printing. By using generative design AI, manufacturers can explore complex and organic geometries that are difficult to achieve through traditional manufacturing methods. This allows for lightweight and optimized designs that take advantage of the unique capabilities of additive manufacturing.

Autodesk Fusion uses generative design, an AI-driven tool that explores multiple design solutions based on user constraints like materials and manufacturing methods. It optimizes product performance, reduces waste, and speeds up innovation. Fusion’s Simulation Extension validates AI-generated designs, while its Manufacturing Extensions automate CAM programming. Other Autodesk tools, like Inventor and Revit, also integrate AI for design optimization. Fusion’s cloud-powered AI makes it accessible and cost-effective for engineers and designers.

Design AI refers to the use of artificial intelligence to assist or automate design processes. It leverages machine learning, generative algorithms, and data analysis to create, optimize, and refine designs faster and more efficiently.

In Autodesk Fusion, Design AI is primarily seen in generative design, where AI explores multiple solutions based on user-defined constraints like materials, weight, and manufacturing methods. It helps engineers and designers innovate, reduce material waste, and improve performance. AI also enhances simulation, automation, and manufacturing workflows, making the design-to-production process smarter and more efficient.

In Autodesk Fusion, generative design and AI-driven simulation empower engineers to design smarter, faster, and more effectively.

Generative design AI enhances rather than replaces human designers. It automates the creation of various design options based on set parameters, freeing designers from repetitive tasks. This allows them to focus on creative decision-making and refining designs, making the process more efficient and innovative.

Autodesk's generative design AI, particularly in Fusion, differs from traditional CAD by automating the creation of multiple optimized solutions based on set goals and constraints. Unlike CAD, which involves manual iterations, generative design explores many alternatives and integrates performance analysis directly into the process. This results in more efficient, innovative, and performance-driven design outcomes.

If you are new to Fusion, generative design AI is available with a subscription to Fusion for Design. If you already own a subscription to Fusion, you can access generative design with the Fusion Simulation Extension.