& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Lean construction is a project management approach that helps maximize the value and minimize the waste of construction projects by helping to streamline processes, improving communication, and reducing delays and rework. Lean construction prioritizes better collaboration between teams, and lean construction tools like last planner system software help foster this. Find out more in our blog post, “What is lean construction?”

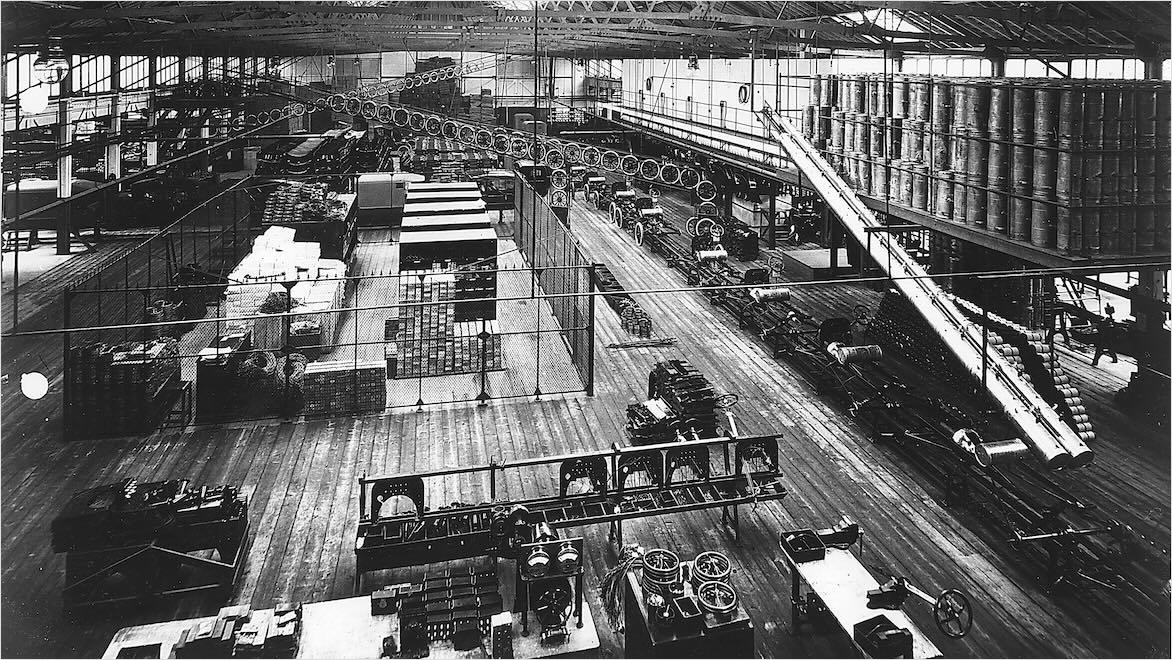

Lean construction has its origins in the early 20th century, in modernized working processes such as the assembly-line production of Henry Ford’s Motel T automobile in 1913. Ford implemented key lean concepts such as standardization of parts and models, waste reduction, and efficient supply chains. Another car manufacturer, Toyota, took the lean concept further, developing the just-in-time concept, where production schedules are determined by demand. Over the latter half of the 20th century, lean methods would take the world by storm, leading to lean construction management.

There are six core principles of lean construction:

Lean construction seeks to recognize what is truly of value to the client and why.

Lean construction ensures that everyone working on a project knows what is important in the project context, so they can add value at each step of the way.

Lean construction management ensures that the project continues to flow smoothly, without disruption to vital processes. Find out more about this flow in our lean construction infographic.

Remove all activities, materials, and steps that do not add value to a project.

Carry out certain phases of construction only when prompted by the completion of previous steps.

Log and analyze constraints and work to eliminate them.

Lean construction software tools offer features that help optimize project workflows through an integrated and scalable approach, ultimately improving productivity, reducing costs, and increasing bottom line.

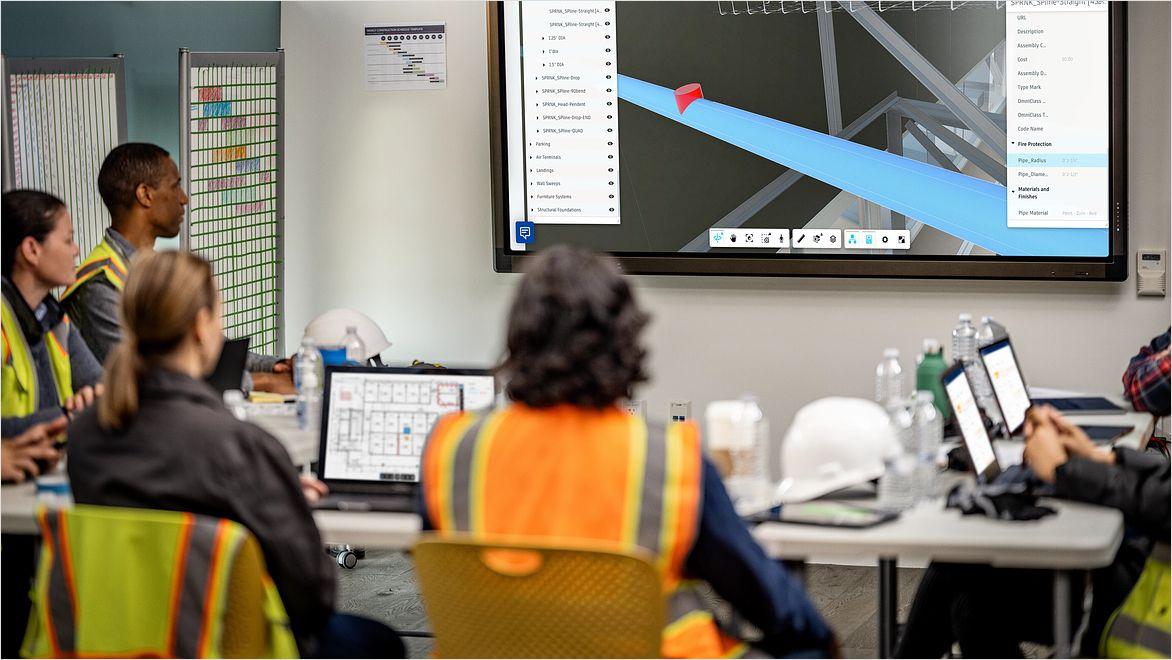

The lean construction planning building information modeling (BIM) process uses a detailed virtual model of a building to identify potential problems, helping to reduce errors and rework and complete the project more efficiently.

Learn about the benefits of lean construction software from Autodesk.

Lean construction planning centralizes construction project schedules to track tasks, milestones, and deadlines.

Communicate with project stakeholders to improve efficiency & decision-making.

Allocate and track resources such as labor, equipment, and materials to reduce waste.

Monitor project progress to identify areas for improvement and increased efficiency.

A last planner system is of great use in lean construction management, leading to reduced waste, and increased value and efficiency. It is a way of coordinating and communicating between the last planners in a project—such as supervisors and heads of design—incorporating pull planning to determine what needs to be done, make-ready planning to ensure the upcoming work is ready to be done, weekly work planning, daily commitment management, and weekly learning. Autodesk’s last planner system software is increasingly being optimized with artificial intelligence to help you refine your last planner system.

Use lean construction principles to complete projects faster and with fewer resources to improve profitability.

Reduce the time spent on costly subcontracting project management tasks.

Increase the amount of data and monitoring across projects to identify issues using lean construction management.

Collaborate with key stakeholders to reduce revisions and improve quality.

Find out more about lean construction management and discover potent lean construction examples in a special episode of Autodesk’s Digital Builder podcast. In the episode “How to maximize value with lean: It’s worth it!” host Eric Thomas talks to Ariana Alvear, production manager at The Boldt Company, about the uses of lean construction, myths and misconceptions, last planner system software, and more. Watch the full episode, recorded at the Autodesk Gallery, for free on YouTube.

Cannistraro

Discover how adopting new technology and lean construction principles helped this mechanical construction firm stay competitive in a rapidly evolving industry.

CRB

Learn how this builder’s integrated approach helps deliver better project outcomes and reduce risk.

MODULAR POWER SOLUTIONS

Find out how one firm reduced waste and increased productivity using lean construction planning.

Helm Mechanical

Learn about the specialty contractor’s approach to cloud-based collaboration and lean construction processes.

Learn more about lean construction software and how it benefits workflows and projects with these resources from Autodesk.

Learn common myths and misconceptions, the role of technology, and the ideal project delivery method with lean construction.

Utilize lean construction principles and technology to improve operations and increase the profit margins and ROI on construction projects.

Lean construction processes support construction teams to achieve better scheduling, win work, improve quality, enhance site safety, and reduce costs while minimizing waste.

Lean construction is a management philosophy adopted from lean manufacturing principles. The main principles of lean construction include:

Lean construction and project management are not the same, but they are closely related. Project management is a broader discipline that involves planning, organizing, directing, and controlling resources to achieve specific project goals and objectives within a given time frame and budget.

On the other hand, lean construction management is a specific management approach derived from lean manufacturing principles, which focus on maximizing value and minimizing waste in construction projects. Lean construction can be considered a subset of project management, as it provides a set of principles and practices that can be applied within the broader context of project management to improve project outcomes.

Lean construction offers several benefits over other project management methodologies due to its focus on maximizing value and minimizing waste. Some of the key benefits of lean construction management include:

Lean construction tools can improve sustainability in the construction industry by enhancing streamlining and improving project quality. Some examples of how lean construction and last-planner system software contribute to sustainability include:

Implementing lean construction in your organization requires a commitment to change and a focus on continuous improvement. Here is a step-by-step approach to help you get started: