& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

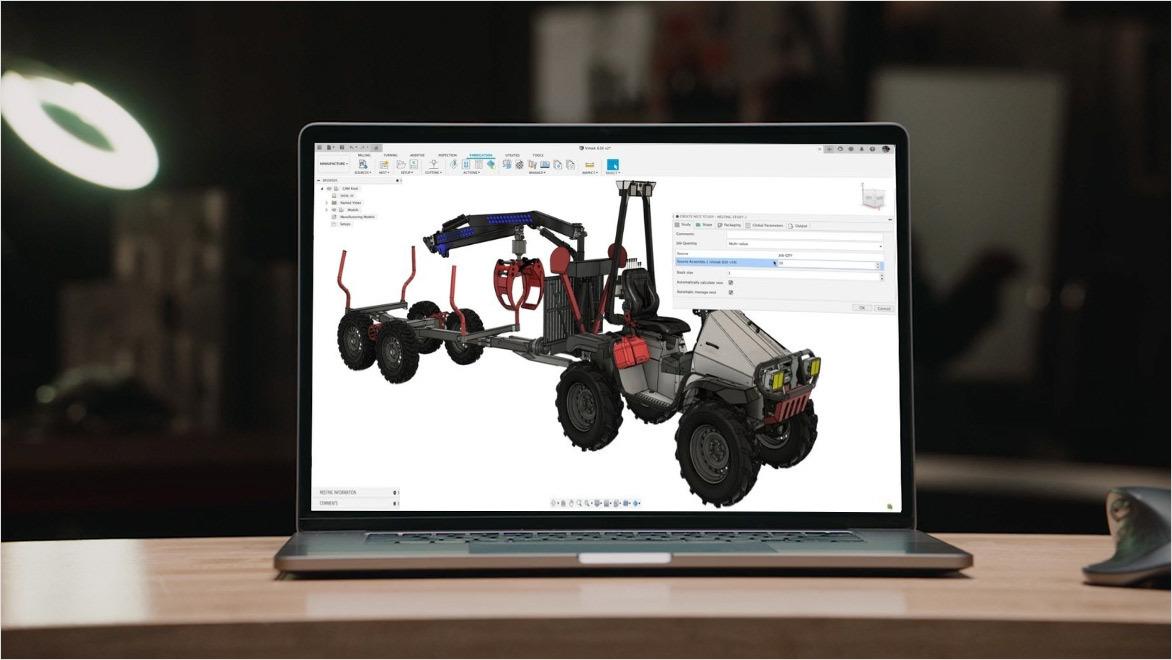

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Nesting is the process of arranging different parts or shapes on a piece of material in a way that uses as much of the material as possible and leaves little waste. This is especially useful in industries that involve cutting materials like metal, wood, or fabric, helping save on costs and reduce waste.

Fabrication is the process of making things by cutting, shaping, and putting together different raw materials, usually metal or plastic. It involves techniques like welding, machining, and forming to build finished parts or structures. You'll find fabrication in action in places like construction sites, car manufacturing, aerospace, and many other manufacturing industries where precise and sturdy products are needed.

Nesting software refers to the process of arranging and optimizing 2D or 3D shapes on a flat sheet of material to maximize utilization and minimize waste. It is particularly useful in industries such as woodworking, sheet metal fabrication, CNC programming, CNC machining, and cutting operations. Nesting software analyzes the shapes to be cut and intelligently arranges them on the material sheet, ensuring the highest material efficiency possible.

By optimizing the layout of parts on a sheet of material, manufacturers can reduce scrap, lower production costs, and enhance overall efficiency. Effective nesting also contributes to sustainability efforts by decreasing the amount of discarded material and promoting the conservation of resources. Nesting software can also improve production speed and accuracy, leading to higher-quality products and increased competitiveness in the market.

Nesting software intelligently arranges parts within a material sheet, optimizing their placement to minimize waste and maximize material usage. This leads to cost savings by reducing the amount of material required for production.

Nesting software streamlines the nesting process, saving time and improving overall production efficiency. By automating the arrangement of parts, it eliminates the need for manual placement, resulting in faster nesting operations and increased productivity.

Nesting software analyzes the geometry of parts and generates optimized cutting paths. By arranging parts in an efficient manner, it reduces the distance the cutting tool needs to travel, minimizing cutting time and improving machine utilization.

Nesting software ensures the precise placement of parts on the material sheet, reducing the risk of errors and improving part quality and accuracy. This is especially important for industries where precision is critical, such as aerospace or automotive manufacturing.

Autodesk nesting tools and software can optimize a variety of nesting types, streamlining your projects.

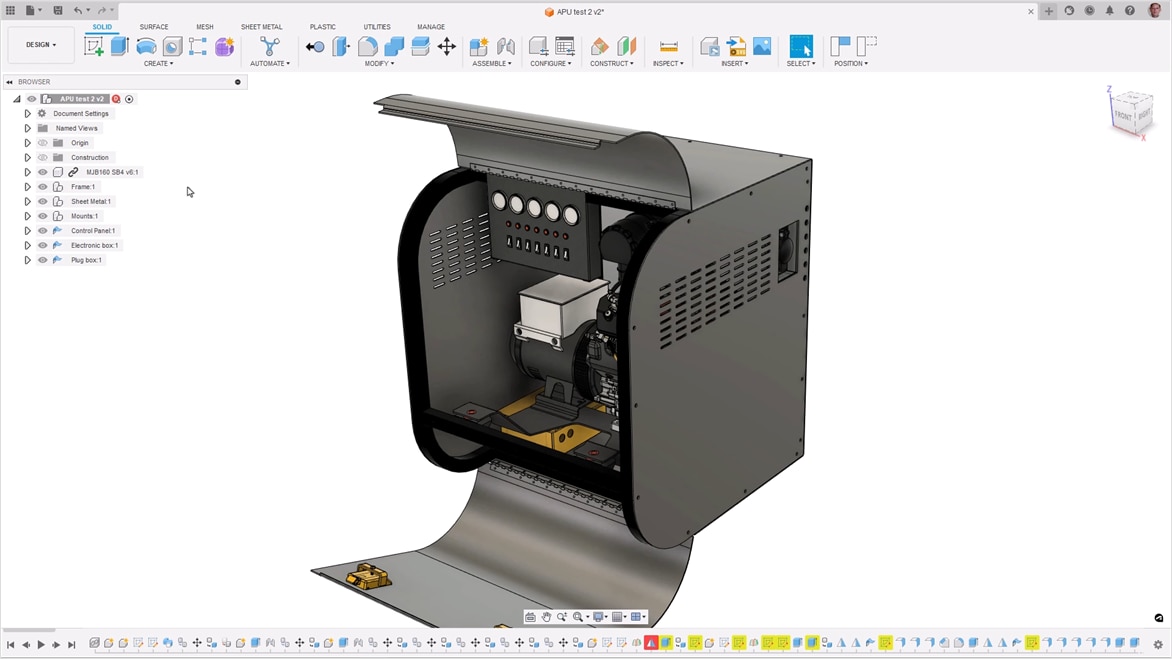

Autodesk Fusion amplifies the benefits and efficiency of automatic nesting while delivering nuanced control and customization options for projects.

Optimize material usage and reduce programming time by using Autodesk Fusion nesting software for intelligent nesting projects to produce complex layouts with speed and accuracy.

Autodesk Fusion nesting software allows you to automate manual nesting to reduce cost and time. It optimizes multi-sheet and multi-material nests to prepare them for CNC machine cutting.

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

Nesting in Fusion employs advanced algorithms that automatically arrange parts within the material sheet, optimizing material usage and minimizing waste. These algorithms take into account factors such as part geometry, material type, and nesting constraints.

With automated nesting, you can save time by eliminating the manual effort required to arrange parts on a sheet. Fusion analyzes the geometry and automatically generates the most efficient layout, freeing up your valuable time for other critical tasks.

Nesting in Fusion supports a wide range of material types, including metals, plastics, composites, and more. It adapts to the specific characteristics of each material, allowing for accurate and efficient nesting regardless of the material being used.

Direct integration enables a smooth transition from the design phase to the nesting process, ensuring data continuity and eliminating the need for manual data transfer.

Fusion provides interactive nesting previews, allowing users to visualize the placement of parts on the material sheet in real-time. This feature helps users make informed decisions and optimize the nest for maximum efficiency.

Autodesk Fusion for Manufacturing is an integrated CAD/CAM platform that combines parametric modeling, DFM, drawings and cloud-based collaboration with:

– Richard Ganas, CEO, GANAS MFG

Nesting software finds applications in various industries and manufacturing processes. Some common examples include:

Nesting software plays a crucial role in optimizing the placement of components for cutting or machining in automotive and aerospace industries, maximizing material utilization, and reducing production costs.

In the woodworking industry, nesting software ensures efficient use of wood panels, reducing material waste and improving yield.

Nesting software is a valuable asset in the realm of CNC machining. By optimizing material usage and generating efficient toolpaths, nesting software greatly enhances the CNC machining process. It helps minimize waste, reduce setup times, and improve overall productivity.

Nesting software helps optimize the layout of sheet metal components, minimizing waste and maximizing the utilization of expensive materials.

By optimizing the placement of 3D printed objects within the print bed, nesting software maximizes print volume, reduces support material usage, and shortens print times.

By arranging parts intelligently, nesting software reduces material waste, minimizes production time, and enhances the overall efficiency of laser cutting operations.

Learn more about nesting software with the following resources from Autodesk.

Learn more about how nests are linked to the design and material settings when making changes and recalculating the nest.

Learn how to nest parts in Fusion using either the nesting or arrange tools.

Learn how to effectively use features, with guided tutorials, of nesting software in Autodesk Fusion.

Learn how to create customizable, printable labels for easier part tracking using nesting in Autodesk Fusion.

Learn about the three methods Fusion offers for 3D nesting: Bounding Box, Monte Carlo, and True Shape.

Nesting in Fusion intelligently arranges parts within a sheet based on predefined parameters and constraints. It utilizes advanced algorithms to optimize material usage and enhance manufacturing efficiency.

Yes, nesting software is compatible with a wide range of materials, including metals, wood, plastics, and composites. It adapts to the specific requirements of each material type to ensure optimal nesting results.

CAD/CAM nesting is the process of efficiently arranging parts to be cut from raw materials, such as sheet metal or fabric, using CAD and CAM software. It maximizes material usage and minimizes waste by automatically optimizing the layout based on part geometry and material constraints.

Yes, nesting software supports both sheet metal and wood cutting. It's used in industries like metal fabrication, woodworking, and furniture manufacturing to optimize material usage, reduce waste, and improve cutting efficiency for materials such as steel, aluminum, plywood, MDF, and more.

Yes, nesting software is suitable for both laser cutting and CNC machining. It helps generate optimized cutting paths and layouts for machines, for the efficient use of materials and reducing machining time.

2D nesting is nesting done on flat materials to create 2D parts and shapes. Examples include sheet metal fabrication and carbon manufacturing.

Common line cutting is when designs for one or more parts share the same edge, reducing material waste. It may speed cutting times of nested sheets and reduce heat-related distortions.

A fly cutter is a single-point rotary cutting tool that moves across the surface of flat materials. Fly cutting uses this tool to make a shallow cut or to level a material's surface.

Bump nesting is the act of manually dropping shapes or part designs onto the sheet layout. It can be used in conjunction with automatic nesting to fill in spaces left after automatic nesting.

The main difference between manual and automated nesting is in how parts are arranged on the material sheet:

Manual nesting involves a user manually placing and rotating parts within a layout. It gives more control but is time-consuming, less efficient, and prone to human error.

Automated nesting uses algorithms to quickly and intelligently arrange parts for optimal material usage. It saves time, reduces waste, and is ideal for complex or high-volume production.

Yes, the nesting functionality in Autodesk Fusion is available free for 30-days. Subscribe to Fusion for Manufacturing to continue using it once the 30-day trial ends.