& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

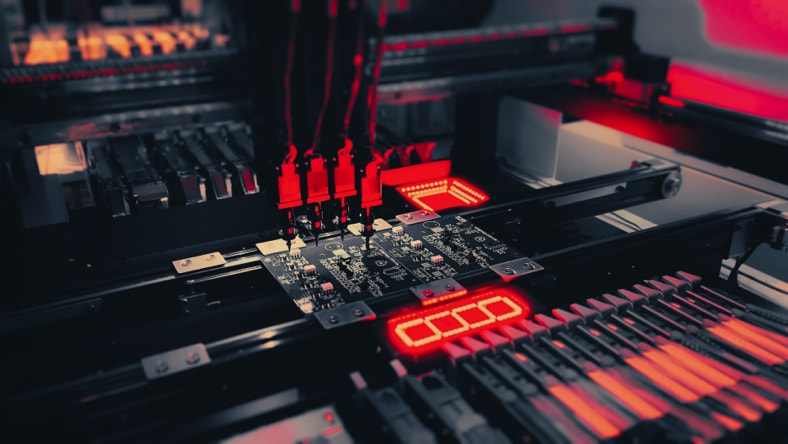

PCB manufacturing is the process of creating Printed Circuit Boards (PCBs), which are essential in connecting and supporting electronic components used in nearly every electronic device. PCBs provide mechanical support and electrical connections. They serve as a physical structure that holds components in place, while also providing the electrical pathways that enable communication between these components.

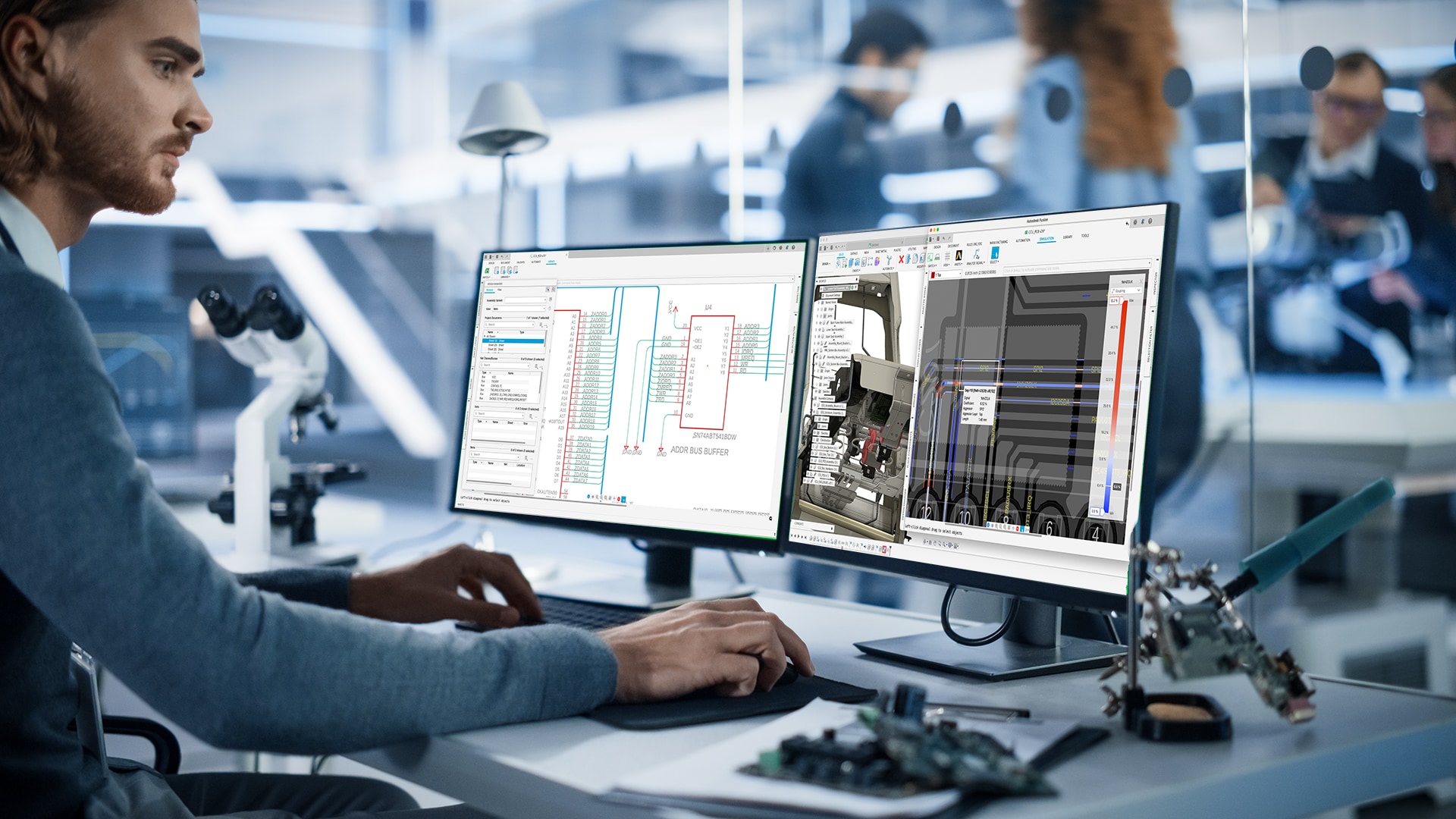

This functionality is achieved through conductive pathways, or "tracks," which are etched from copper sheets and laminated onto a non-conductive substrate, such as epoxy. The process begins with the design of the PCB layout using specialized PCB manufacturing software. This software helps engineers position the components and route the electrical connections, ensuring the design is optimized for production.

PCB manufacturing software, also called PCB fabrication software, helps engineers and designers create layouts for printed circuit boards. This software allows users to design the board's layout, connect components, and run simulations to check for errors. It also creates files like Gerber files, a standard format for PCB manufacturing.

PCB manufacturing software is essential because it simplifies the process of designing and producing circuit boards that power modern electronics. Without this software, creating even a basic circuit board would take more time and be prone to errors, making it difficult to scale production.

Take smartphones, for example—without efficient PCB manufacturing, we wouldn’t be able to mass-produce the complex circuits that make them function. PCB software automates key parts of the design process, making it easier to create reliable, high-quality designs that are ready for manufacturing. It ensures that your designs can smoothly transition into production, which is essential for minimizing errors, delays, and material waste.

Optimize PCB design electromagnetic performance by controlling the impedance of every critical transmission line.

PCB assembly and manufacturing software, like Autodesk Fusion, enhances the productivity and effectiveness of the design and manufacturing processes, leading to higher-quality PCBs, reduced development time, improved collaboration, and increased cost savings.

PCB software, like Autodesk Fusion, offers powerful tools that allow engineers to quickly create, modify, and optimize circuit layouts. This streamlines the design process and ensures that boards meet manufacturer specifications.

Teams can collaborate in real-time, share files, and manage versions, making it easy to exchange feedback and track changes throughout the development process.

Built-in design rule checks (DRC) ensure that the board layout follows industry and manufacturing standards. Simulations can also predict electrical performance and potential issues, helping resolve them before production.

PCB software provides tools to optimize designs for manufacturing, helping identify problems with component placement, spacing, or solderability. This reduces the chances of a rework, minimizes errors, and cuts down on production costs.

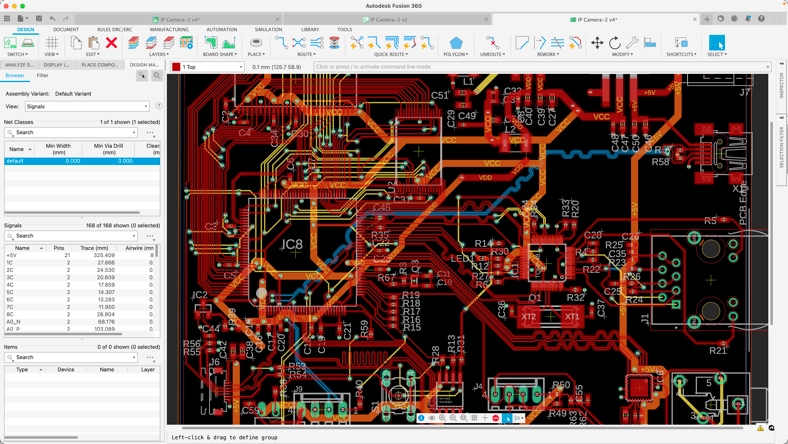

Autodesk Fusion is a powerful tool for modern product design. Its electronics workspace is essential for developing components that make products work. One critical step in the PCB design process is generating the files needed for manufacturing. This used to be a complicated, error-prone task, but Fusion simplifies it into a few easy steps.

Fusion offers standard outputs like Gerber and drill files, which are accepted by all manufacturers. It also includes advanced options like ODB++, which allows for manufacturer simulations. Whether you need a one-click export or a detailed, configurable computer-aided manufacturing (CAM) export, Fusion has you covered.

Fusion provides advanced simulation tools to evaluate the electrical performance of PCB designs. You can run tests like thermal and electromagnetic interference (EMI) analysis to make sure your designs are optimized and reliable.

Fusion’s layout capabilities make it easy for engineers to create detailed circuit board designs. It ensures that designs perform well, are reliable, and can be manufactured smoothly. With features like efficient routing and design rule checks, Fusion helps streamline the process.

Fusion's library editor makes managing component libraries simple. You can create, edit, and share libraries with ease, and it includes templates for IPC-compliant footprints and 3D models. This saves time and helps maintain an organized collection of components.

Fusion offers powerful 3D visualization, letting you see your PCB design as a complete, three-dimensional model. This helps spot potential issues like mechanical clashes and allows for better design decisions.

Fusion's Design Rule Checking (DRC) automatically scans your PCB layout to ensure it meets predefined standards. With real-time feedback and error detection, you can catch mistakes early, reduce the number of prototypes, and get your product to the end user faster.

Turning a PCB from an idea into a finished product involves three main stages:

The first step is taking the concept for a circuit board and creating a detailed design file. PCB design software helps engineers build schematics and refine layouts, making sure components are placed efficiently for the best performance.

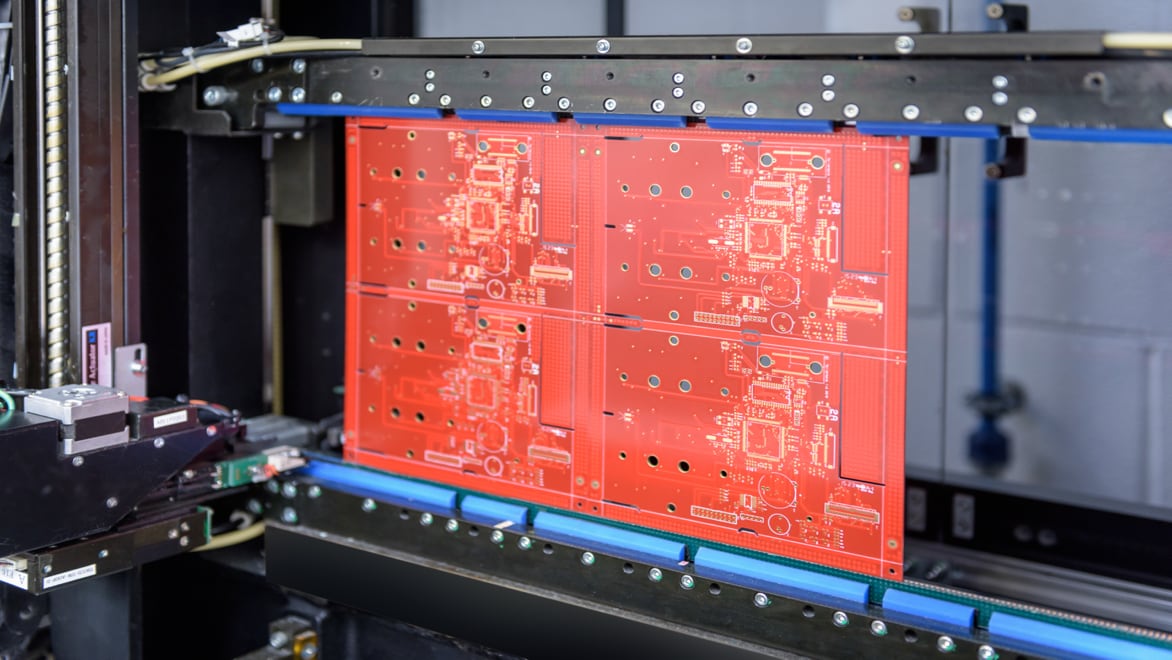

PCB fabrication is where the physical board is made. During fabrication, manufacturers follow the design specifications to create the PCB’s layers, etch the copper pathways, and prepare the board for assembly.

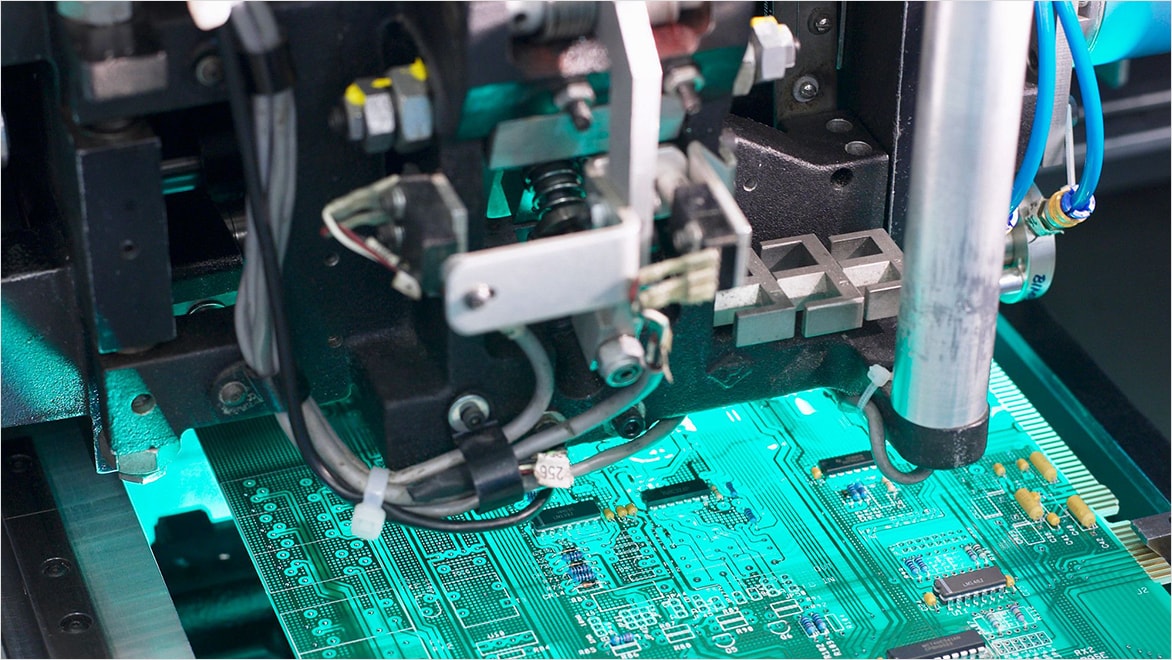

In the final stage, PCB assembly (PCBA), the components are mounted onto the board. This is done through a soldering process that attaches each piece to the correct spot—following the design layout—and ensures the board is ready to function.

PCB manufacturing software is used to design and create electronic components found in industries making everything from consumer electronics to advanced medical devices. Here are some key applications:

From smartphones and tablets to gaming consoles and wearables, PCBs are essential for many of the devices we use every day.

Cars rely on PCBs for engine control units (ECUs), infotainment systems, sensors, and advanced driver-assistance systems (ADAS).

PCB software is used to design control boards for factory machines, including programmable logic controllers (PLCs), motor controls, and sensors used in manufacturing.

In aerospace, PCBs are critical for communication systems, radar, drones, and navigation equipment.

Robots need PCBs for controlling motors, sensors, and processing information, all of which are designed using PCB software.

PCB software helps create precise electronic components for devices like patient monitors, diagnostic machines, portable ECGs, and implantable devices.

Learn more about PCB manufacturing with the following resources from Autodesk.

Follow this PCB manufacturing advice, and your PCBs will not only cost less but will also have fewer production failures and overall better quality.

Don’t break the bank—save money with these ten practical PCB manufacturing tips.

Ever wonder what kind of Design for Manufacturing (DFM) mistakes drive your PCB manufacturer absolutely crazy? Learn about the top 10 so you don’t make them in the future.

Explore courses and skills that help you become an Autodesk Certified Associate in CAM for 2.5 Axis Milling. Learn at your own pace, track your progress, and determine your path forward.

Whether you’re new to PCB design or a seasoned pro who’s learning Autodesk Fusion, here’s how to work with 3D PCB in Fusion.

PCB design revisions used to be costly and time-consuming. Not anymore! Here’s why PCB designers need 3D modeling software.

PCB manufacturing software is a tool that helps engineers and designers create, simulate, and optimize printed circuit boards (PCBs) for electronics. It ensures the board design is ready for production and minimizes errors.

It streamlines the design process, reduces the risk of errors, and ensures that the designs can be easily turned into physical products. This speeds up production and lowers costs.

Yes, you can import existing PCB designs from other PCB design software or file formats into Fusion. Fusion's import functionality allows you to retain the integrity of your design and continue working on it within the software.

PCB software automatically checks for design mistakes, like incorrect connections or spacing issues, before manufacturing starts. This prevents errors that could result in defective or non-functional boards.

Key features include design automation, error checking, collaboration tools, 3D visualization, and integration with manufacturing systems to ensure the design is accurately translated into production.

Yes, advanced PCB software can manage intricate, multi-layer designs that are used in everything from simple gadgets to complex machinery, making it ideal for a wide range of products.

Yes, many PCB software platforms integrate with CAM tools, allowing designs to be sent directly to manufacturing machines for production.

3D visualization allows designers to see a realistic model of the PCB before production, making it easier to spot design issues like component spacing and interference between parts.

Most PCB software comes with built-in rules that ensure designs meet industry standards and manufacturing tolerances, reducing the likelihood of issues during production.

Most PCB software is designed to be user-friendly. With proper training, a designer can become proficient in a few weeks. However, advanced features may take longer to master.

Several different factors will affect the cost of PCB Manufacturing software, but in general, you can expect them to be between $500 and $4000 per year (subscription).