& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Sustainability concerns are escalating. Driven by diverse factors from regulatory changes to consumer demand and pressure from investors, businesses need to adapt if they want to thrive. Autodesk's innovative solutions enable companies to enhance production processes, reduce waste, and foster a greener future for your business. Read our e-book to explore these topics and discover practical ways to approach sustainable manufacturing.

Switch to lighter, better performing, and less carbon-intensive materials to reduce environmental impact and promote resource efficiency.

Minimize unnecessary materials use and maximize materials efficiency to save costs, conserve resources, and promote a more circular economy.

Model, simulate, analyze, and visualize systems to improve processes, reduce waste, and increase efficiencies in energy and water consumption.

Embed sustainability into development decisions by adopting technologies that provide visibility into compliance with environmental standards and regulations.

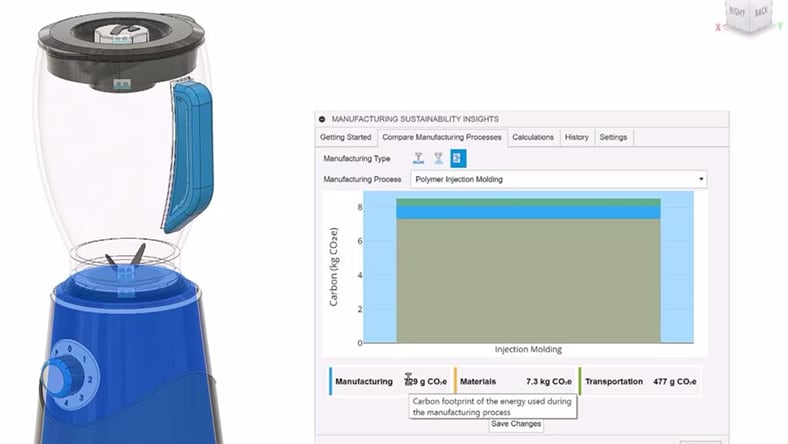

The MSI add-on for Autodesk Fusion offers unparalleled and real-time visibility into the carbon impact of design and manufacturing variables, including material selection, manufacturing process, and geography.

FlexSim enables simulation and analysis of factory resource flows, such as energy and waste, to identify bottlenecks and improve overall efficiency. FlexSim provides a risk-free virtual environment to test “what if” scenarios and discover optimal solutions.

Using generative design in Autodesk Fusion, designers and engineers can reduce embodied carbon and energy by identifying opportunities for lightweight parts, consolidating assemblies, and even exploring different material and design options.

Achieve sustainable design with Inventor. Inventor enables efficient, sustainable design with capabilities for optimizing material use, ensuring durability, and improving product quality.

The collection enhances sustainability by streamlining processes, improving collaboration, and implementing smart manufacturing practices to reduce material use and environmental impact.

Monitor sustainability data with Vault. Vault organizes, manages, and tracks sustainability data to ensure product quality and compliance across the supply chain.

Sustainability software

Connected to the Makersite platform, the Makersite Fusion and Inventor add-ons return CO2eq and cost impacts of designs directly within the CAD environment.

Lifecycle Assessment Software

The EcoDesigner web application, powered by SimaPro, connects to the Autodesk Platform and enables anyone to calculate and access lifecycle assessment (LCA) insights across multiple impact categories.

Autodesk program

Autodesk’s STPP supports impact partners across design and make with tools, resources, and technical support to build sustainability-focused integrations on the Autodesk Platform.

Article

Learn how the Manufacturing Sustainability Insights (MSI) add-on for Autodesk Fusion helps you discover the carbon impact of your design decisions.

Article

Read how Fusion empowers engineers to create more sustainable products with material selection tools, energy consumption analyses, and lifecycle assessments.

Article

Explore how Fusion helps businesses reduce waste and optimize resources during product development for a competitive edge in today’s sustainability-conscious market.

Sustainability in manufacturing refers to the practice of creating products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources. It involves reducing waste, lowering emissions, and utilizing sustainable materials and energy sources to ensure that production processes are environmentally responsible and resource-efficient.

Sustainable manufacturing is important because it reduces environmental impact by minimizing waste and conserving resources, thereby protecting the environment. It enhances efficiency and reduces costs, complying with regulations and improving brand image by attracting eco-conscious consumers. Additionally, it drives innovation and ensures long-term business viability by addressing resource scarcity and future-proofing operations.

Some sustainable manufacturing processes include using renewable energy sources, implementing waste reduction and recycling programs, adopting energy-efficient technologies, utilizing sustainable materials, and optimizing production to minimize resource use and emissions.

Circular design within sustainability is an approach that focuses on designing products and systems to be regenerative and restorative by intent. It emphasizes minimizing waste and maximizing the lifecycle of materials by creating products that can be reused, repaired, remanufactured, and recycled, thus maintaining the value of resources for as long as possible and reducing the need for new raw materials.

Lifecycle assessment (LCA) is needed in sustainability because it provides a comprehensive evaluation of the environmental impacts associated with all stages of a product’s life, from raw material extraction to disposal. This helps identify areas for improvement, reduce negative environmental impacts, enhance resource efficiency, inform decision-making, and ensure that sustainability efforts are effective and not just shifting impacts from one stage to another.

Sustainable water management involves the efficient and responsible use, treatment, and conservation of water resources to meet current and future human, environmental, and economic needs. It includes practices such as reducing water waste, recycling and reusing water, protecting water quality, and ensuring equitable access to clean water, all while maintaining the health of aquatic ecosystems.

Sustainability can improve manufacturing processes by making them more efficient, reducing waste, and cutting costs. For example, energy-efficient machinery can lower electricity consumption, while waste reduction can decrease disposal costs.

Autodesk supports sustainability in manufacturing through its software solutions that enable manufacturers to design, simulate, and produce more sustainable products. This includes tools for energy efficiency, waste reduction, and the use of sustainable materials.

Sustainable manufacturing can lead to cost savings, improved brand reputation, increased customer loyalty, and compliance with environmental regulations. It can also contribute to a circular economy, where resources are kept in use for as long as possible.

Sustainable manufacturing can have a positive impact on the supply chain by reducing waste, improving efficiency, and promoting responsible sourcing of materials. It can also help companies meet consumer demand for products that are ethically and sustainably produced.

Autodesk solutions can help manufacturers reduce their carbon footprint by enabling them to design, simulate, and produce products using less energy and fewer resources. Autodesk's software can also help in optimizing manufacturing processes to reduce waste and emissions.

Digital technology plays a crucial role in sustainable manufacturing by enabling manufacturers to design, simulate, and control production processes with precision. This can result in less waste, lower energy use, and improved product quality.

The circular economy is a model that aims to keep resources in use for as long as possible. In sustainable manufacturing, this can mean designing products for longevity, using recyclable materials, and creating processes that can reuse or recycle waste.

Autodesk's vision for the future of sustainable manufacturing is a world where manufacturers can create products without negative environmental impact. Autodesk supports this vision through its software solutions that enable sustainable design and manufacturing practices.