& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

A water jet, also known as a water jet cutter, is a machine that uses a high-pressure jet of water to cut or shape various materials. It is a versatile cutting tool used in industries such as manufacturing, engineering, and fabrication.

Water jet cutting works by pressurizing water and directing it through a small orifice at very high speeds. The pressure is typically generated by a high-pressure pump, which can produce pressures up to 90,000 pounds per square inch (psi) or sometimes even higher.

Water jet cutting can produce intricate shapes and is used for both straight cuts and complex curves. This is a preferred method for cutting materials that may be too delicate for other processes or where minimal material wastage is desired.

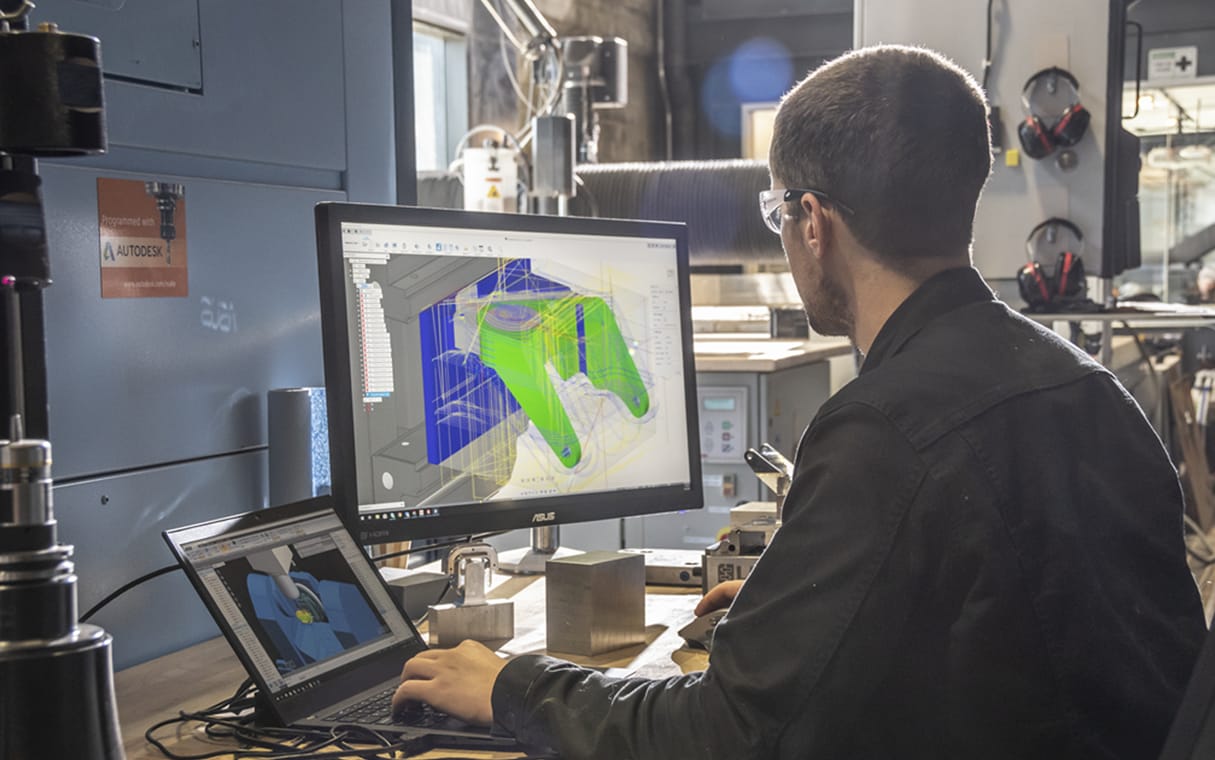

Water jet cutting software revolutionizes the manufacturing process by granting manufacturers full control over water jet machines. With CAM software, manufacturers can gain access to powerful tools for directing and regulating water jet nozzles across multiple axes, ranging from 2D to 5-axis capabilities.

This technology allows the creation of intricate features on a wide range of materials. This includes metals, wood, composites, sheet products, stone, foam, and plastic. The result is the production of high-quality components in large quantities, with exceptional precision and efficiency.

Water jet cutting and laser cutting offer distinct advantages depending on the requirements of a project. Laser cutting uses a high-powered, heat-intensive laser to cut metals, plastics, and composites. It's particularly effective for thinner materials, yet it introduces the possibility of heat-affected zones (HAZ), potentially altering material properties around the cut.

Water jet cutting is ideal for precise, clean cuts and utilizes a cold-cutting process that protects material integrity and avoids the risk of distortion due to thermal stress. It is optimal for cutting thicker materials including steel, aluminum, titanium, plastics, and copper. Water jet cutting can handle a wider range of materials, making it a versatile choice for many applications where preserving material integrity is crucial.

See examples of industries utilizing water jet cutting for manufacturing.

Water jet cutting is used to make a wide range of component parts commonly found in vehicles. This includes interior trim, body panels (in both metals and fiber-glass), exhaust and braking systems, insulation, gaskets, bumpers, and more.

Water jet cutting is used to make component parts including body parts, cabin panels, custom structural parts, and landing gear. It is also used for processing exotic alloys found in engine components such as turbines and guide vanes.

Water jet cutting software is frequently used to make parts and components in the medical equipment industry. These include items such as surgical instruments, artificial limbs, braces, prototypes, and orthopedic appliances.

Water jet cutting is used to make sheet metal parts for different industries. Parts are cut to size and specification before being assembled for use in building enclosures, furniture, architectural works, or food and beverage components.

Water jet cutting is used to cut a wide range of materials such as metals, stone, tiles, and marble. It is also effective for slicing granite, concrete, glass, composite materials, insulation, bespoke elements, and other architectural components.

Water jet cutting is used in the electronics sector to cut aluminum, copper plates, insulators, and heat sinks. It is also used to cut electronic enclosures, metal panels, gaskets and seals, flexible circuits, ceramic substrates, alloys, and plastics.

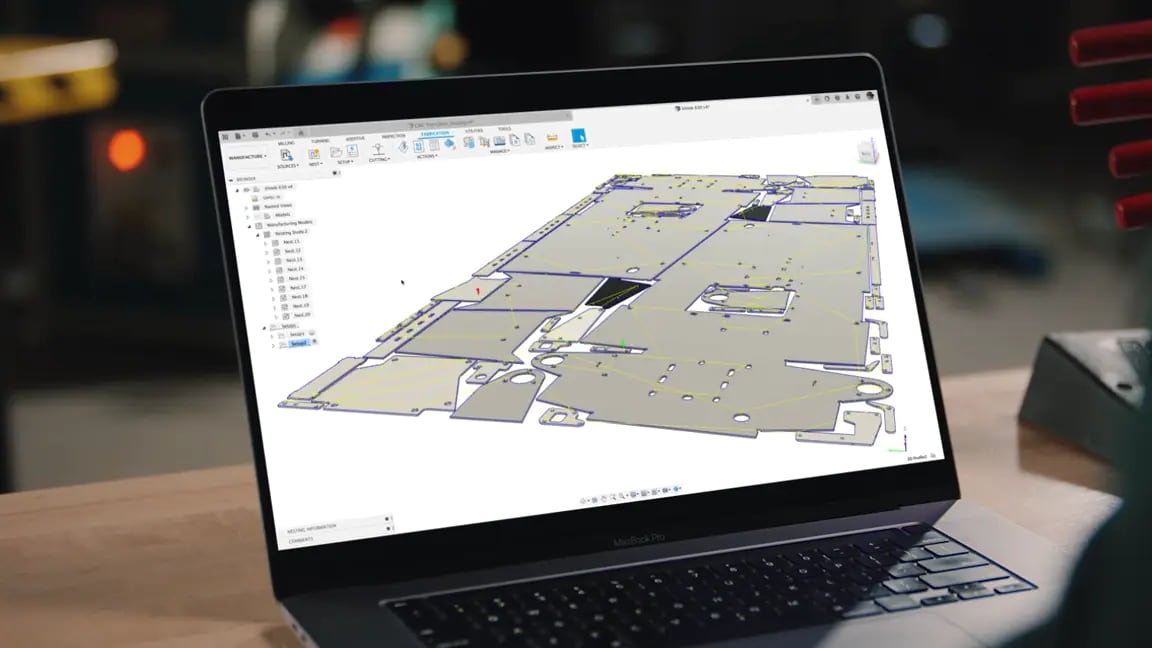

Whether you're importing existing 2D designs or starting from scratch, the intuitive interface in Autodesk Fusion allows you to sketch and define complex geometries with ease, along with providing complete control over dimensions, tolerances, and other design parameters, ensuring your designs are accurate and precise.

Maximize efficiency and minimize waste while saving time and money by fine-tuning feed rates, and cutting speeds to achieve optimal results for different materials and thicknesses.

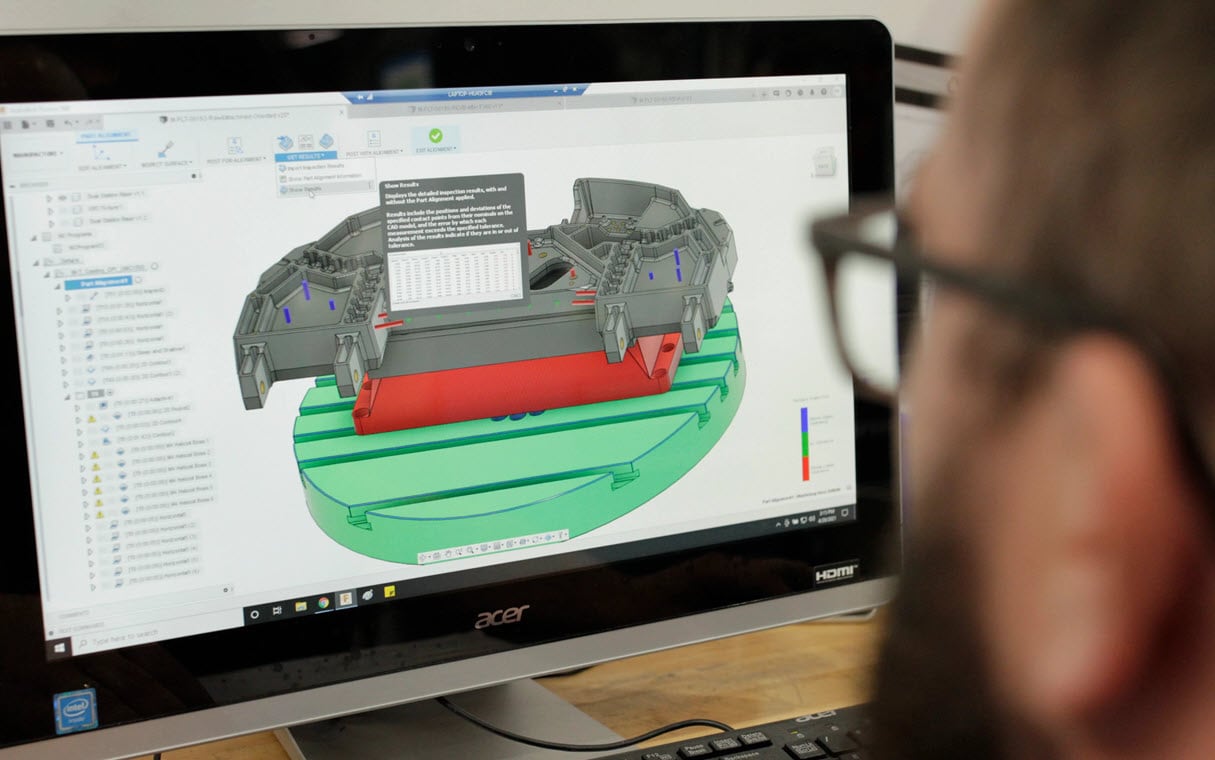

Eliminate guesswork and reduce errors with simulation tools in Autodesk Fusion. Visualize and verify the entire waterjet cutting process before execution.

Catch potential issues in the virtual environment to avoid costly mistakes and achieve the highest level of precision in your cuts.

Autodesk Fusion simplifies the process of generating G-code, by automatically generating machine-readable G-code based on your design and toolpath parameters. This seamless integration ensures compatibility with a wide range of water jet cutting machines and enables smooth communication between the software and the hardware.

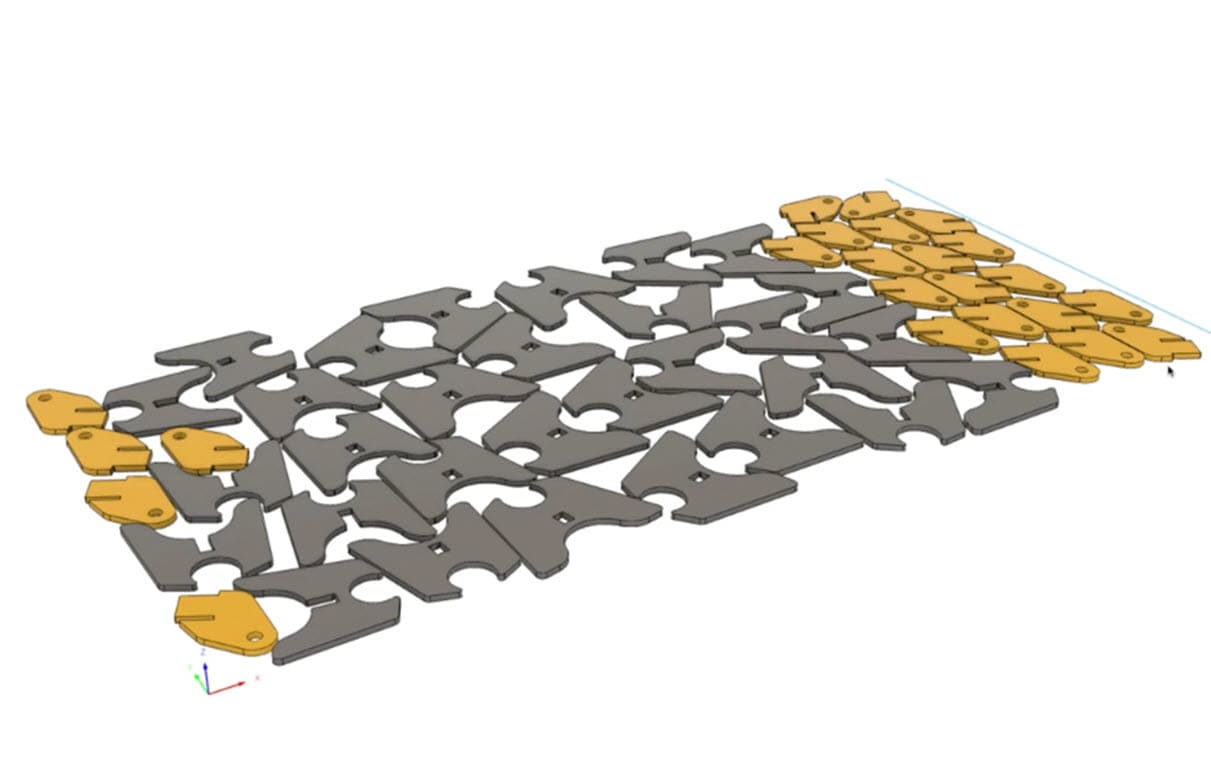

The Fusion Manufacturing Extension optimizes material usage by arranging multiple parts on a single sheet of material, helping to minimize water jet cutting waste and maximize efficiency.

Water jet cutting can achieve high levels of accuracy with profile tolerances of ±0.1mm. This accuracy means water jet cutting can match the stringent standards for automotive, aerospace, consumer products, and more.

Water jet machining creates high-quality, warp-resistant parts with minimum heat. CAM software controls nozzle pressure, traverse speeds, lead-in/out motions, and more.

Water jet machining is efficient because tool nozzles may be swapped to alter kerf thicknesses. This lowers machine downtime and increases flexibility.

Water jet cutting software's nesting tools enable batch manufacturing. Automated layering streamlines CAM programming, reducing human error. It reduces waste, boosts output, and cuts labor expenses.

Water jet machines come in many varieties and are classified by material size. Some waterjet cutters have specialized abrasives and nozzles for certain materials.

As the name suggests, water-only cutting use high-pressure without abrasive. While these water jet cutters can lack the power to cut through certain metals, they are a solid option for materials like foam, rubber, plastics, wood, softer composites, and several other materials.

Abrasive water jets are best suited to cutting through harder materials. They use pressurized water mixed combined with abrasive media to provide the extra power required for harder metals. The use of different abrasives types and sizes helps produce specific surface finishes.

High-pressure water jet cutting combines abrasive media with water pressures exceeding 50,000 psi. While not every material needs this pressure - this is an ideal choice when processing exotic materials including carbon fiber, ballistic materials, and Nickel-based alloys such as Inconel.

Learn what materials are typically used with water jet cutters.

A wide range of organic materials including different types of wood, stone, and ceramics.

A diverse range of metals including different grades of steel, Inconel, Titanium, and Aluminum.

More advanced composites including ballistic materials, plastics, and carbon fiber.

Waterjet cutting is used to cut hard and soft materials precisely. Waterjet cutting doesn't heat the workpiece like other methods. This improves quality, consistency, and compliance. These industries and projects employ waterjet cutting software technology.

Water jet cutting is used to make a wide range of component parts commonly found in vehicles. This includes interior trim, body panels (in both metals and fiber-glass), exhaust and braking systems, insulation, gaskets, bumpers, and more.

Water jet cutting is used to make component parts including body parts, cabin panels, custom structural parts, and landing gear. It is also used for processing exotic alloys found in engine components such as turbines and guide vanes.

Water jet cutting software is frequently used to make parts and components in the medical equipment industry. These include items such as surgical instruments, artificial limbs, braces, prototypes, and orthopedic appliances.

Water jet cutting is used to make sheet metal parts for different industries. Parts are cut to size and specification before being assembled for use in building enclosures, furniture, architectural works, or food and beverage components.

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

Learn more about water jet cutting software with the following resources from Autodesk.

Explore how Autodesk Fusion offers various solutions for 2D cutting, including for water jet, laser cutter, or plasma table projects.

Get a detailed description of parameters in the water jet tool reference for Fusion.

Learn the steps needed to export a 3D model to .dxf format in Fusion, to then use the sketch for CNC routing, plasma cutting, laser cutting, or water jet cutting.

Learn how to streamline and simplify the CNC programming process with Fusion. Design 3D models, generate toolpaths, simulate operations to avoid errors, and automatically produce G-code, enhancing efficiency, precision, and flexibility in manufacturing operations.

Discover how precision machining operates and produces complex parts with the tightest tolerances required by the most demanding industries.

Learn the steps needed to export a 3D model to .dxf format in Autodesk Fusion, to then use the sketch for CNC routing, plasma cutting, laser cutting, or water jet cutting.

Understand more about water jet cutting with frequently asked user questions.

Yes, water jet cutting software like Autodesk Fusion can be run on both PC and Apple Mac hardware.

A water jet can cut any type of metal, like aluminum, brass, copper, Titanium, and stainless steel. The most powerful waterjet machines can even cut through diamonds.

Water jet cutting machinery is supplied as a complete working solution and contains all of the hardware and consumable elements required. In addition, it is preferable to invest in CAM software that can generate NC machining code to tell the CNC machine what to do.

The answer depends on the material being processed. High-pressure water jet machines can easily cut through hard materials up to 300mm thick. It is worth noting that cutting speed will generally need to reduce as material thickness increases to achieve acceptable levels of quality.

Autodesk provides a range of manufacturing software with the ability to generate high-quality NC code that can be used to drive CNC mills and routers. This includes 2-axis, 3-axis, and 5-axis machines, CNC lathes (including multi-tasking machines), mill-turn machines, as well as laser and plasma cutting machines.

We are present everywhere you want us to be. Getting started with us is way simpler than you can imagine! Contact us today to learn more about how our water jet cutting software can enhance productivity and reduce setup time for your business. Our team will provide you with detailed information, answer any additional questions you may have, and guide you through the process of implementing our software for your business.

Water jet cutting is a preferred solution in multiple industries due to its numerous benefits including its ability to cut materials without generating heat while preventing thermal distortion and hardening, ensuring material integrity. It cuts a diverse range of materials, including metals, composites, stones, and plastics, with a high level of precision. Water jet cutting produces smooth edges around cuts in many cases minimizing the need for additional finishing steps.

Water jet cutting software enhances efficiency by automating the creation of precise toolpaths, which optimizes the cutting process and minimizes material waste. Additionally, it integrates seamlessly with CAD/CAM systems, allowing for swift adjustments and accurate execution of complex designs, reducing overall production time.

Water jet cutting is a process that employs a high-pressure stream of water, or a mixture of water and an abrasive substance, to cut through various materials. The water is pressurized to around 60,000 PSI and, if needed, combined with an abrasive like garnet. This mixture is then directed through a small nozzle, where it exits at high speeds, capable of eroding material at the atomic level. The path of the jet is controlled by a computer, allowing for precise, detailed cuts. Notably, water jet cutting does not generate heat, preventing thermal distortion or hardening of the material, making it an environmentally friendly and versatile cutting method.