Tulip

Tulip is helping companies improve productivity, quality, and performance by digitizing workshops with enhanced machine monitoring.

Tulip is helping companies improve productivity, quality, and performance by digitizing workshops with enhanced machine monitoring.

Area of Research:

Manufacturing, IoT, Edge Computing

Location:

Boston

While automation has helped to improve many frontline operations, several complex tasks are still done manually. Platforms that can digitally monitor machines, provide work instructions, and track quality systems, have the potential to transform workshops. Modern, IoT platforms make it easier to identify issues before they can impact a project and empower the people who often do the most challenging jobs to focus on what they do best instead of monitoring machine performance.

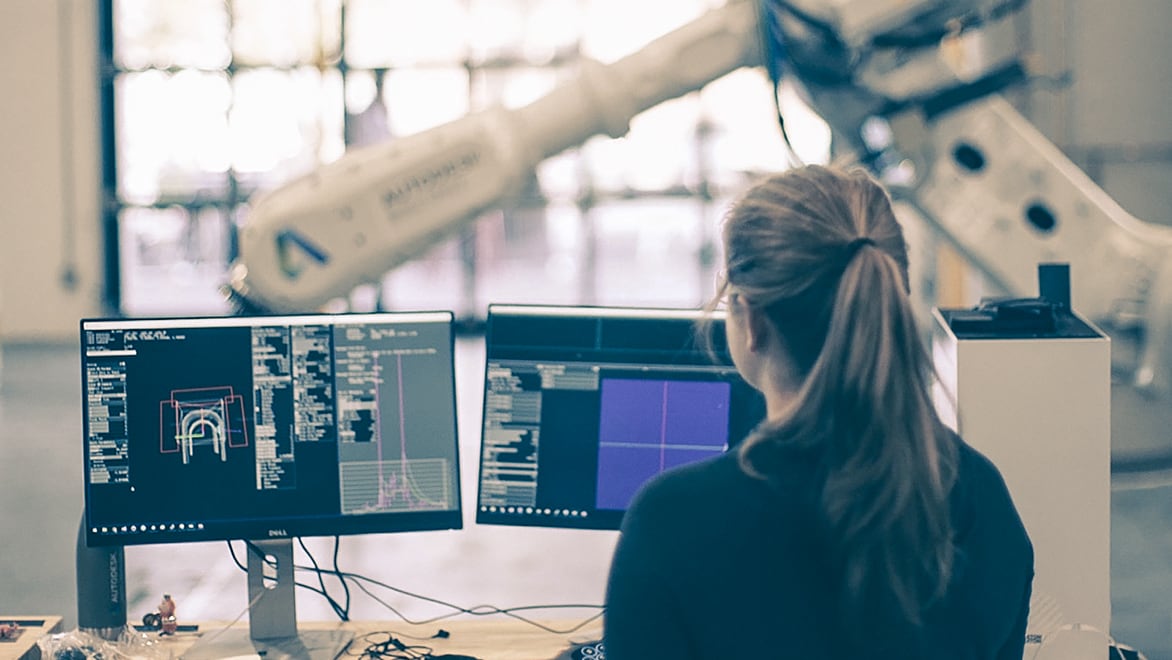

Tulip is helping to solve these challenges and modernize workshops by adding digital monitoring capabilities to analog devices. A resident of the Autodesk Technology Centers Outsight Network, Tulip is a frontline operations platform company that connects people, machines, devices, and systems used in a physical location. As they started to develop their newest Edge devices, the Tulip team turned to the Technology Centers for product testing and support.

The Edge IO, Tulip’s recently announced wireless edge device, was tested at the Boston Technology Center. The device collects data from sensors embedded on specialized equipment and machines to help detect anomalies, and through a cloud dashboard, lets operators know when there’s a problem or potential issue. The Technology Centers team uses Tulip’s Edge IO device to monitor the woodshop dust collection. With an integrated app and logic, the data collected by the Edge IO triggers an action letting the team know when the machine is turned on and working properly, or when the bin needs to be emptied. This helps prevent waste overflow and other problems in this crucial system, to ensure projects are completed without timely delays.

By implementing the Tulip platform in the workshop, the Technology Centers team has a better understanding of how the platform works and how to best maximize the benefits of Edge technology on analog devices in a real-world setting. This allowed both companies to analyze the role data plays in workshops and how that information can be used to improve and enhance machine performance, leading to smarter and more modern shops. Both teams also learned more about potential customer issues with traditional analog devices, how they can benefit from a more digitized workshop, and where there might be challenges in implementation.

This collaboration contributed to Autodesk’s efforts to help companies create connected workshops, where machines, workshop processes, and facilities are better integrated to break down boundaries between design-and-make workflow. Working with Tulip and its Edge IO platform, Autodesk gleaned valuable insight into data-informed decision making in workshops and more information on how companies can create smarter shops. Tulip also gained several key connections and customers and will use knowledge from their time at the Technology Center to do more exploration on machine learning and AI for frontline operations.

Tulip is demonstrating how the combination of Edge computing devices and sensors paired with an easy-to-use dashboard can be applied to help monitor production and perform real-time quality assurance in a more connected workshop.

The residency program provides open workspaces and equipment for teams doing forward-looking work in the areas of construction, manufacturing, and emerging technologies.