Integrated factory modelling

Optimise your facilities layout for efficiency and innovation

Unlock the power of integrated collaboration by coordinating factory line layout, production equipment and building systems in one holistic, digital model.

Integrated factory modelling

Unlock the power of integrated collaboration by coordinating factory line layout, production equipment and building systems in one holistic, digital model.

Integrated factory modelling is a process combining BIM and digital factory planning to generate a digital representation of a facility and production equipment. Pair 3D CAD with data management, building modelling and reality capture tools to optimise your process along with the factory design itself.

When the market drives change, retool and reconfigure the factory even faster to improve time to market.

Coordinate the many complex disciplines involved on factory projects in a common data platform.

Offer more value to manufacturing clients by extending critical services across the factory lifecycle.

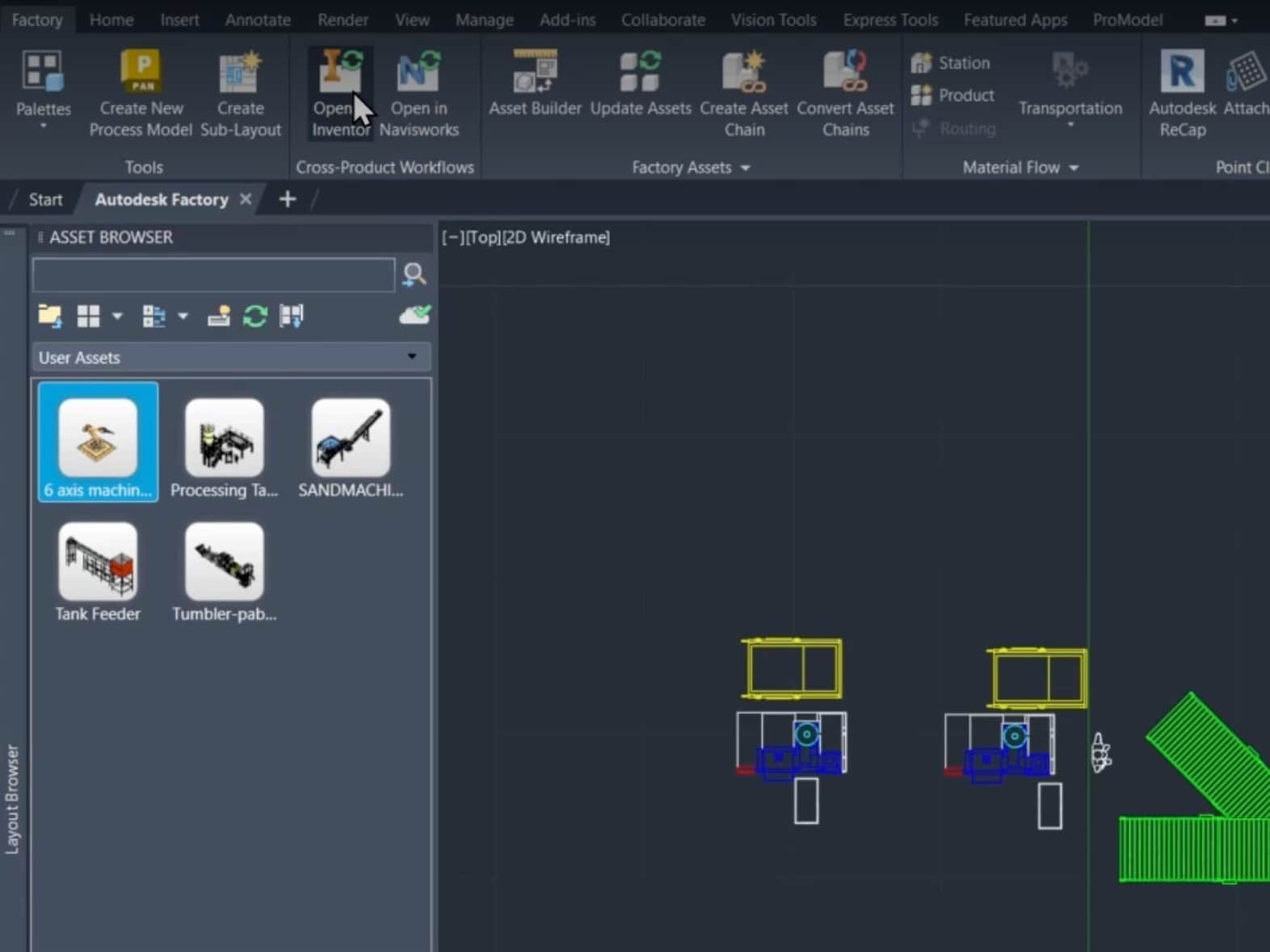

Design factory layouts with familiar 2D workflows, then visualise the facility in a fully integrated 3D environment.

Easily explore what-if scenarios before you even start placing equipment to find the optimal layout and process.

Use laser scan data to measure, markup and run clash detections between point clouds of the existing facility and equipment.

Avoid unwanted surprises during installation by checking for clashes and space constraints right inside the digital factory model.

Realise the benefits of connected people, processes and data as you manage change orders, bills of material and the supply chain.

Author configurable equipment assets that can be placed into your factory layout and shared via desktop or the cloud.

Plan, design, construct and manage buildings with powerful tools for Building Information Modelling.

2D and 3D CAD tools, with enhanced insights, AI-automations and collaboration features. Subscription includes AutoCAD on desktop, web, mobile and seven specialised toolsets.

Navisworks Manage, Navisworks Simulate software and the Navisworks Freedom 3D viewer for 5D analysis, design simulation and project review.

Cloud-based design co-authoring, collaboration and coordination software for architecture, engineering and construction teams. “Pro” enables anytime, anywhere collaboration in Revit, Civil 3D and AutoCAD Plant 3D.

Autodesk partner ProModel can help you model, study and optimise your production line concept. Execute factory design and process optimisation simultaneously in AutoCAD with ProModel.

As a global leader in the integration of architecture, engineering, construction, product design and manufacturing processes, Autodesk can help you develop the capabilities needed to achieve your goals.

Contact us today to learn more about subscription and purchasing options for integrated factory modelling solutions with an Autodesk expert.