DESIGN & MANUFACTURING

CAD interoperability

Seamlessly exchange CAD data from virtually any source while maintaining your data integrity.

DESIGN & MANUFACTURING

Seamlessly exchange CAD data from virtually any source while maintaining your data integrity.

Eliminate redundant costs caused by multiple CAD platforms and varying standards for different engineering departments.

Avoid time-consuming and frustrating steps needed to repair CAD file translation errors on an ongoing basis.

Confidently work with imported CAD data without risk of missed interferences, corrupted data or other downstream issues.

Use automated tools to simplify files and remove proprietary information prior to sharing with suppliers and clients.

The product development process involves collaboration between multiple teams and shared CAD data from various software applications. From changing your CAD software to collaborating with other teams and suppliers, discover the top use cases for robust interoperability.

Read virtually any CAD file without translation and convert designs from one CAD file format to another.

Choose between translating data to allow for editing or maintaining associative references to the original file so models automatically update whenever source files change.

Use automated tools to remove unnecessary details from your models, protecting intellectual property and reducing file sizes for easier exchange with your customers and suppliers.

Associatively reference models created in SOLIDWORKS, Creo, CATIA, NX, Solid Edge, STEP, Fusion 360, Revit and Alias without translation.

Select only which portions of the referenced data you want to include in your design upon import. You can even edit your selection later if you change your mind.

Open files saved in the next release of Inventor for single-year backwards compatibility.

Import and export building information models natively from Revit to reference as you model BIM objects or customised-fabricated designs.

Define how properties from each file type map to Inventor file properties to minimise manual re-entry of metadata.

Associatively reference native DWG files into your 3D models to use as the basis for part modelling or assembly skeletal modelling.

KALITTA MOTORSPORTS

Kalitta Motorsports uses the Product Design & Manufacturing Collection to save design and manufacturing time and optimize their overall operations.

"We started in 2015 machining our clutch assemblies and now we are doing clutch assemblies, cylinder heads, and so many more parts. It is a huge cost savings and so much more efficient." – Chad Head, General Manager at Kalitta Motorsports

Image courtesy of Kalitta Motorsports

Learn how to overcome everyday challenges and work better internally, externally and with your supply chain.

Read how building product manufacturers can create BIM content from their CAD models with the appropriate level of detail.

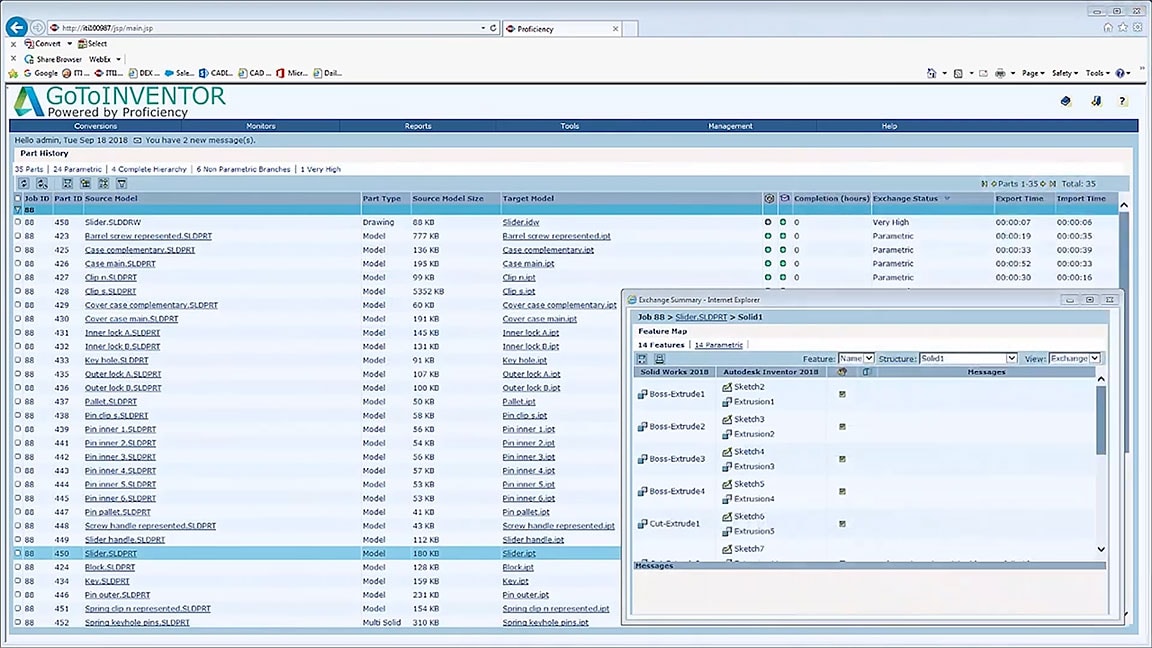

Learn how Autodesk partner ITI can help you to automate the migration of intelligent, fully featured CAD data from CATIA V5, NX, Creo/Wildfire, Solid Edge and SOLIDWORKS.

Image courtesy of ITI

As a global leader in the integration of architecture, engineering, construction, product design and manufacturing processes, Autodesk can help you to develop the capabilities needed to achieve your goals.

Keep in touch today to schedule your business consultation.

3D CAD conversion is the process of translating a non-native 3D model, metadata (property information) and sometimes feature history into the destination 3D CAD software. With Autodesk Inventor, no conversion is needed: You can simply open non-native CAD files without translation.

A CAD file translator is a tool that allows 3D models to be imported and exported between different software programs.

Once a 3D CAD file is created, it becomes the centre for all downstream applications. Previously, engineers would need to translate 3D CAD files depending on which application the file would be opened in. Now, 3D model files can be opened without translation for use in all downstream applications, like CAM or simulation.