& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Automotive part manufacturing is the process of designing, fabricating and machining parts for a wide range of vehicles. This spans from trucks and SUVs to Formula 1 racing cars and buses. Automotive engineers who work for prominent, aftermarket, and start-up companies are typically the profession carrying out this process.

Automotive engineers take an initial conceptual vehicle, conceived by automotive designers, and determine the methods to design and manufacture every part needed to bring it to life. The engineering teams are tasked with the design, prototyping, testing and production of each part before the assembly of the final vehicle.

The automotive industry moves fast, especially startup and aftermarket automotive companies which must react quickly to evolving industry standards and consumer demand. Automotive engineers need a tool that helps them create each part efficiently without sacrificing quality. Automotive part design and manufacturing software enables engineers to 3D model, validate and fabricate any type of part, from chassis to engines.

An integrated platform for 3D modelling, simulation, manufacturing and collaboration streamlines the design process, reduces production costs and accelerates time-to-market.

The automotive part design process often involves multiple teams. Tools like real-time updates, link sharing and automated drawings enable you to easily collaborate with internal and external stakeholders.

Designing quickly does not mean sacrificing quality. Streamlining the design process in one tool gives increased control over each design, leading to more reliable products.

Automotive parts must be designed and manufactured to perform its intended function, both reliablity and efficiently.

Automotive part materials must be considered to ensure performance, weight and cost.

Automotive part design must take into account if the manufacturing processes needed are achievable.

Make sure parts fit together precisely, ensuring the proper tolerances of your manufacturing processes when design and manufacturing parts.

Aim to minimise cost by simplifying the design, reducing material usage or optimising the manufacturing process without compromising quality.

Ensure parts comply with regulations and standards around safety, emissions and recyclability.

Parts should be designed and manufactured to withstand the rigour of expected usage and be as maintenance-free as possible.

Consider the sustainability of the part, including the materials used to manufacture it to the impact it will have over its life cycle.

Automotive part manufacturing software enables you to create any vehicle part you desire, including but not limited to:

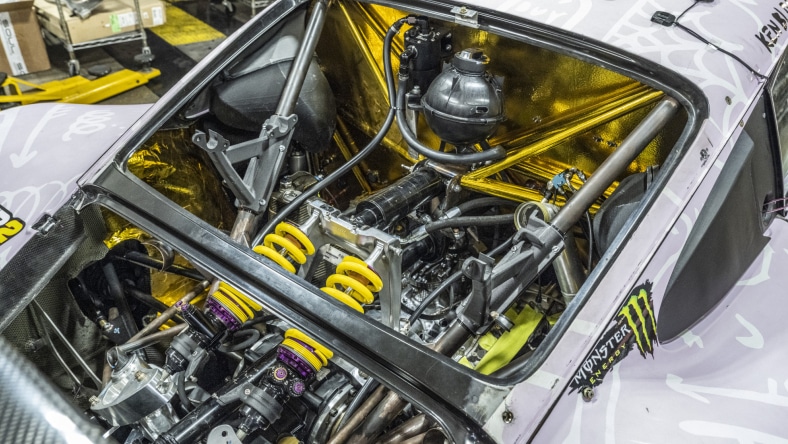

It's vital to engineer a reliable chassis design, as it's the foundation of any vehicle. Each chassis is designed differently depending on vehicle requirements.

When designing an exhaust pipe, it's important to test different materials and designs, predict potential issues and ensure compliance with environmental standards.

Brake performance and longetivity is top priority. Automotive part design software helps to ensure accurate modelling, material selection and performance.

The engine is the heart of any automotive vehicle. Designing a successful engine presents many complex challenges, as engineers need to achieve optimal performance, fuel efficiency, durability and reliability.

Autodesk Fusion is unique in that it offers an all-in-one platform for 3D modelling, simulation, CAM and collaboration. This means you can design, test and manufacture automotive parts all within a single software, streamlining your workflow and increasing efficiency.

Whether you're a small business or a large enterprise, Fusion enables your team to create complex and detailed automotive parts. It's a scalable solution that grows with your business, offering more advanced features as you need them. Fusion also has an active community on its user forums and offers an array of learning content and direct support options.

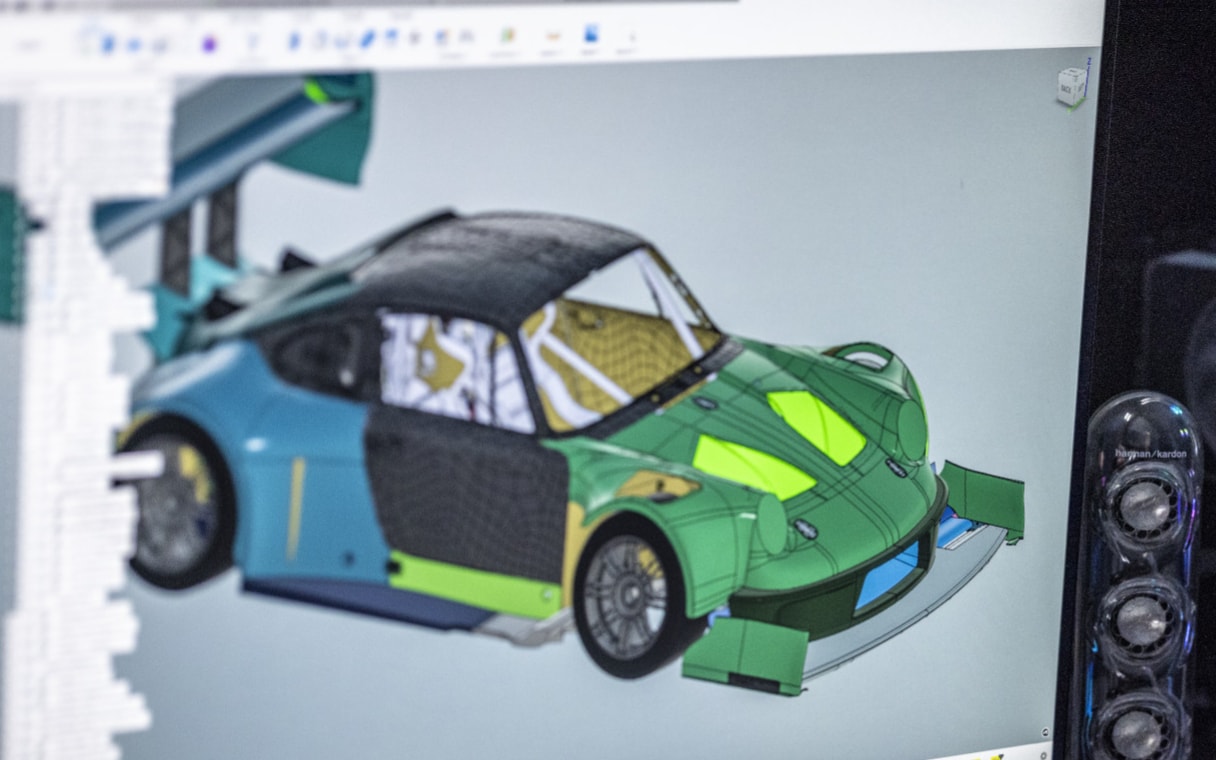

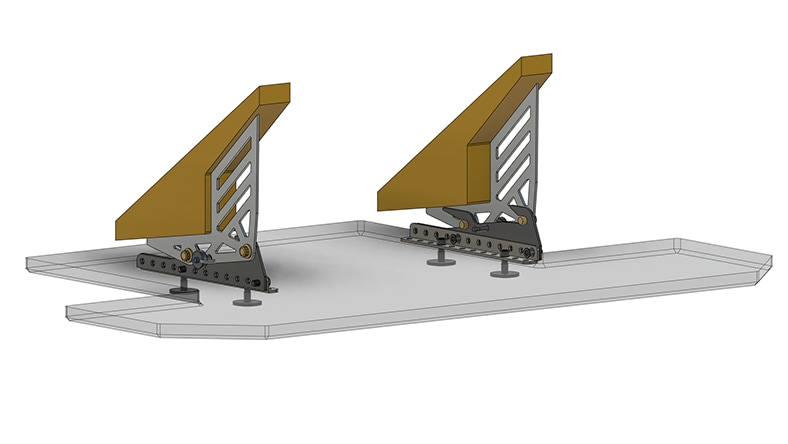

3D modelling with Autodesk Fusion enables you to bring parts from 2D to 3D, preparing them for manufacture. Fusion offers various tools for creating, modifying and refining 3D models, from free-form modelling and surface modelling to parametric design and direct modelling.

Also, configurations (US Site) make it possible to create multiple variations of the same design. This opens the door to more possibilities like easily designing a full product range using the same base 3D model or even iterating on a digital prototype without losing the original version.

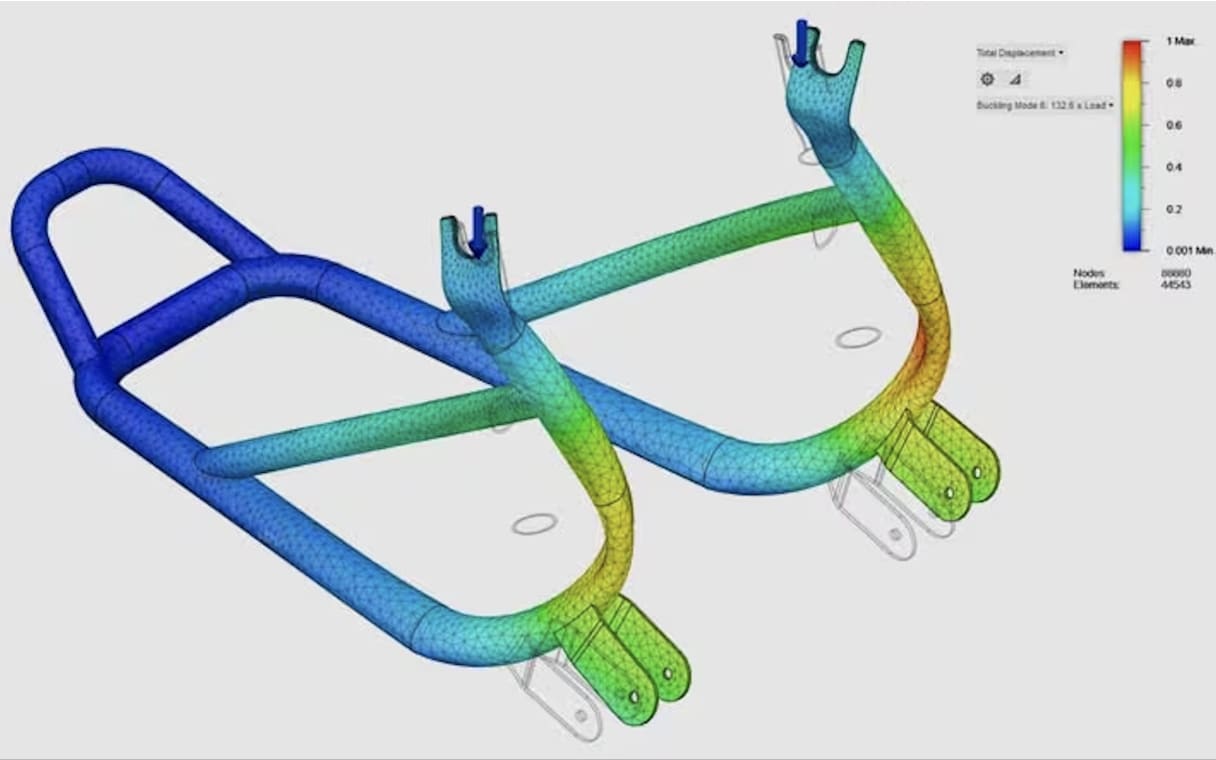

Autodesk Fusion's simulation tools enable designers to validate their designs under real-world conditions. The opportunity to test designs ahead of physical prototyping or manufacturing enables engineers to identify potential design flaws without lwasting time or budget.

The Fusion Simulation Extension includes fluid dynamics tools that help simulate fluid flow, heat transfer and other related phenomena inside or around a part. This is crucial in the automotive engineering field, especially when designing hydraulics, as fluid behaviour significantly impacts part performance.

Autodesk Fusion's integrated CAD/CAM tools enable you to transition seamlessly from design to manufacturing within the same platform, eliminating the need for file transfers and reducing the risk of errors.

It offers a wide range of CAM functionalities, including 2.5-, 3-, 4- and 5-axis milling, turning, and water jet, laser and plasma cutting, enabling you to handle diverse automotive part manufacturing tasks with precision.

With Autodesk Fusion's cloud-based platform, teams can collaborate on designs in real time from any location. It tracks all version histories, making it simple to access past iterations or undo changes when needed.

Fusion also allows for the secure sharing of designs with collaborators like internal stakeholders and clients, making it easy to get feedback while still maintaining control over project access. It also enables collaborators to leave comments directly on 3D models to streamline communication. Also, tools like an integrated bill of materials (BOM) (US Site) simplify the process of tracking important project data.

Optimise part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection moulding and more.

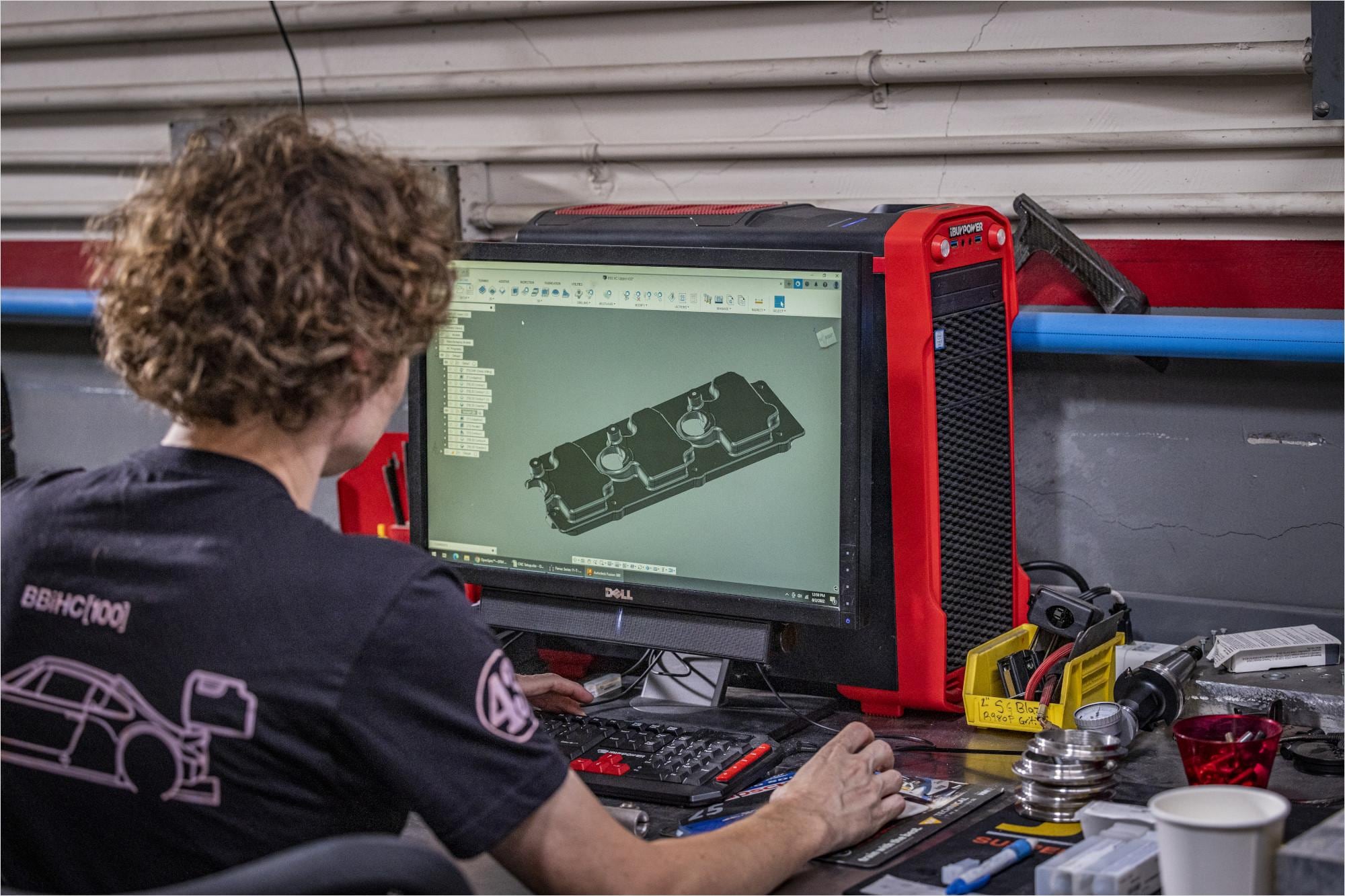

The BBi Autosport team adopted Autodesk Fusion because it needed a CAD/CAM solution that would allow them to develop products concurrently and outside the boundaries of traditional 3D modelling software. See how BBi used Fusion to design and build the impressive Hoonipigasus.

You can’t miss a Rivian truck or SUV on the road. There simply isn’t anything like them. Take an inside look at how the rapid prototyping group within Rivian’s Special Projects team uses Fusion to make fast and reliable prototypes — from 3D modelling to advanced manufacturing with the Manufacturing Extension.

Mike Burroughs is the editor-in-chief of Stanceworks, an online journal featuring modified cars focused on stance culture. He's also an accomplished car builder who documents exciting car builds on YouTube. Watch Mike talk about all things car design, including the future of car customisation on the Shop Talk Podcast.

ICON designs and produces some of the most creative vehicles in the world. Each ICON vehicle is built with a mixture of vintage parts and modern, bespoke parts designed in-house. See how the unique automotive business uses Autodesk Fusion to bring the ”heart and soul” of vintage vehicles while still meeting modern expectations.

Get started with CAE with these informational blog posts.

Explore how the aftermarket automotive industry fits into the larger automotive industry landscape and what makes aftermarket automotive part design unique.

How do companies come out on top in the fast-paced aftermarket automotive industry? Cloud-based product development tools like Autodesk Fusion.

Explore the world of Computer Aided Engineering (CAE), highlighting its crucial role in modern product development.

3D modelling, simulation and analysis, manufacturing, and data management are all beneficial tools to look for when selecting automotive part design software. Autodesk Fusion is unique as it integrates CAD, CAM and CAE tools in one cloud-based platform, allowing for a seamless workflow from design to fabrication.

Yes! It's typical for automotive engineers to use multiple programs when designing a full car or even a part. Autodesk Fusion has a vast partner network with many add-ins that make it easy to use Fusion alongside your favourite CNC machines, 3D printers, laser cutters or even your go-to third-party fabrication companies like Xometry or SendCutSend. Also, Fusion also offers a simple file import process, making uploading scan data or files from other 3D modelling tools straightforward.

With Fusion, you can easily share project links with external collaborators so that they can view progress and provide feedback. If your collaborators also use Fusion, you can work on the same design together in real time. If you're working with external manufacturers to produce your part, the Drawings workspace in Fusion can automatically generate accurate technical drawings (US Site) based on your 3D models. This simplifies the tedious task of creating drawings from scratch and streamlines communications with factories.

Automotive part manufacturing is a sector within the larger automotive industry that focuses on the production of components used in the assembly of vehicles. This includes a wide range of parts such as engines, body parts, interiors, electrical and electronic equipment, and more.

Manufacturers in this sector use a variety of processes to produce these parts, including casting, forging, machining and injection moulding among others. The manufacturing process often involves the use of automated machinery and assembly lines to achieve high volume production.

Yes, Autodesk Fusion is a popular software used in automotive part design. Fusion offers tools and techniques for importing and preparing geometry for simulation, including generative design. It's a comprehensive platform for 3D modelling, CAD, CAM, CAE and PCB, which helps in designing and engineering automotive parts to ensure their aesthetics, form, fit and function.