See how the engineers at LifeFuels broke down the traditional ECAD / MCAD silos to quickly go from zero to a fully functional prototype.

FUSION 360 CUSTOMER STORIES

See how customers are using Fusion 360

Learn how others are using Fusion 360 to design, engineer, and manufacture high-quality products.

-

![]()

LifeFuels

-

![]()

MJK Performance

MJK Performance designs and manufactures high quality, precision CNC machined motorcycle parts.

-

![]()

Coalesse

Coalesse, a division of Steelcase, has standardized Fusion 360 across its organization to create office furnishings with the goal of maximizing collaboration in the workplace.

-

![]()

SRAM

SRAM, a worldwide leader in cycling componentry, continues to push the envelope in stiffness, weight, and cost by using generative design in Fusion 360.

-

![]()

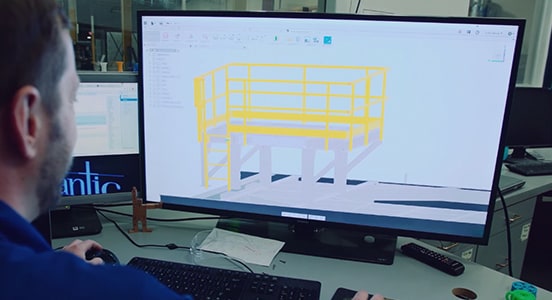

Advantic

Advantic, an expert in composite materials, uses Fusion 360 not only as a design tool but for sales, marketing, production, and customer service.

-

![]()

Swissomation

Swissomation, an expert in machining, micromachining, and prototyping uses Fusion 360 to machine small micro-parts.

-

![]()

Orange County Choppers

Orange County Choppers simplified their product development process by designing and fabricating a one-of-a-kind all-electric bike completely using Fusion 360.

-

![]()

Saunders Machine Works

Saunders Machine Works uses Fusion 360 and specialises in CNC metal machining, prototype machining, fabrication and design-for-manufacturing consulting.

-

![]()

Oru Kayak

Oru Kayak is using Fusion 360 throughout their entire product development process to revolutionise the kayak industry by creating easily transportable folding kayaks.

-

![]()

Grovemade

Grovemade uses Fusion 360 to create an asthetically appealling set of desktop speakers using a mix of maple and walnut wood.

-

![]()

KMP Motorsports

KMP Motorsports uses Fusion 360 as an all-in-one solution to bring innovative products to motorsport industry faster.

-

![]()

Photosynth

Photosynth used Fusion 360 to develop Akerun, a smart lock device connected to the Internet that can lock or unlock your door from your smartphone.

-

![]()

Edera Safety

Edera Safety uses generative design technology in Fusion 360 to create a better and more efficient back protector.

-

![]()

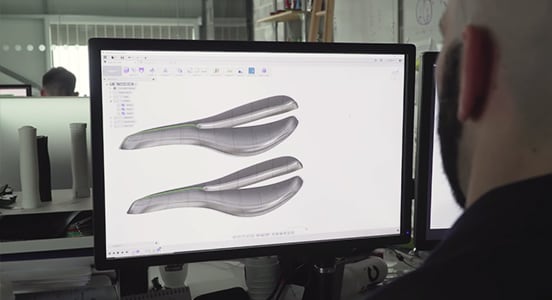

Fabric

Fabric is using Fusion 360 to speed up their product development process as they bring award-winning cycling products to market.

-

![]()

SEAM

See how SEAM is designing faster and collaborating more efficiently using Fusion 360 to create new personal safety technology.

-

![]()

NXT Factory

NXT Factory has developed a new 3D printer and workflow to finally enable 3D printing for production level product manufacturing.