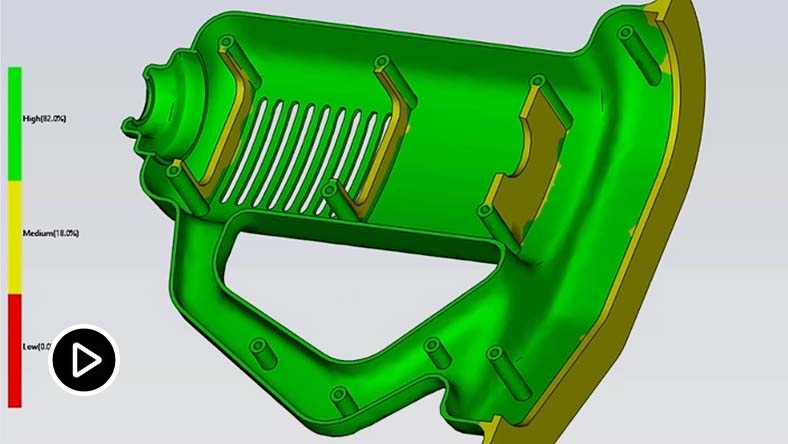

Moldflow Adviser provides manufacturability guidance and directional feedback for thermoplastic part and mould designs through high-level material flow, mould cooling and part warpage results.

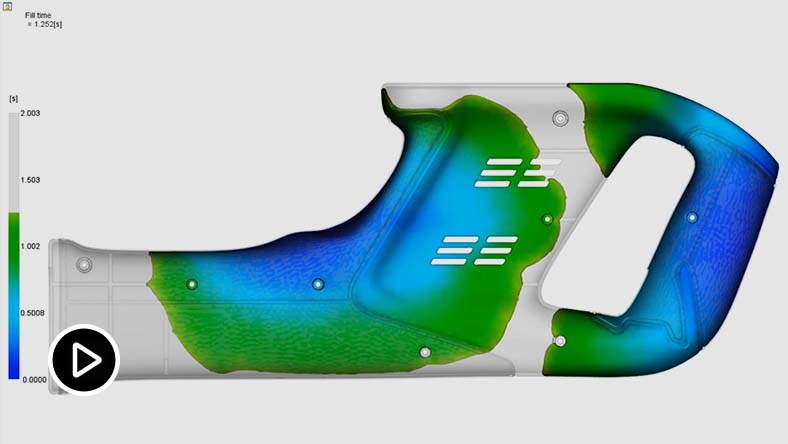

Moldflow Insight provides detailed material flow, cooling and warpage results for both injection moulding and compression moulding processes. Additional control on materials, machines, moulds and processes is possible with Moldflow Insight.

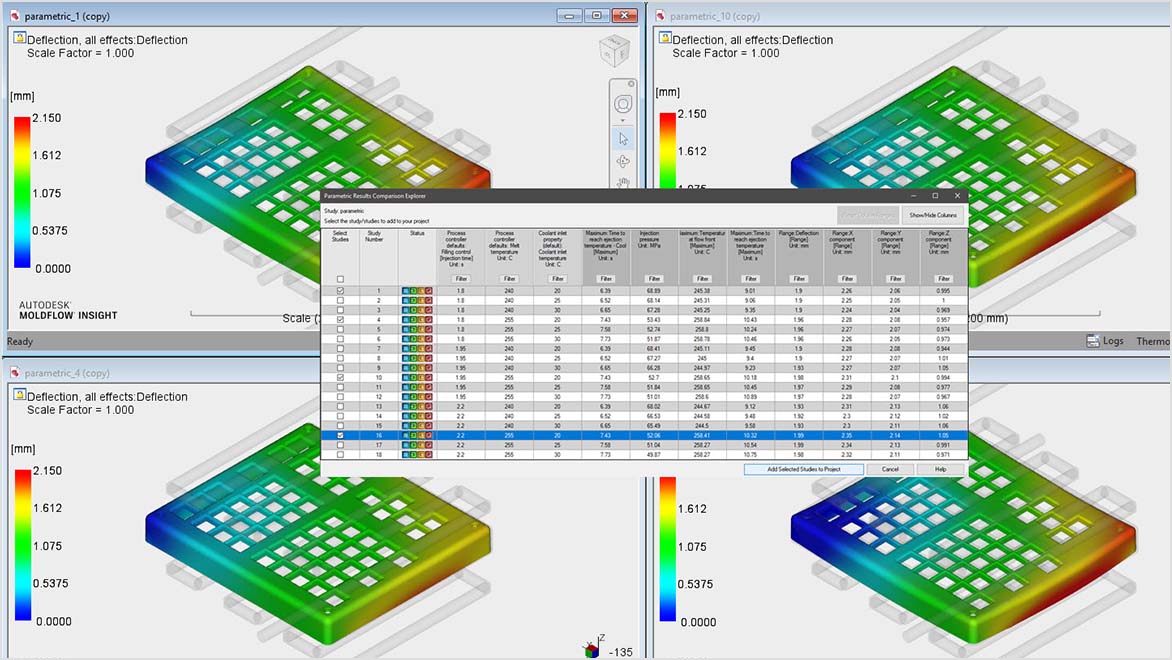

Automation with scripts/API accelerate setup and post-processing capabilities. Thermoplastic and thermoset materials are supported, along with customisation of materials for part inserts and mould inserts. Advanced moulding methods, such as gas-assisted injection moulding, injection compression moulding, co-injection moulding, microcellular injection moulding and many more, are available to discover the best option for your part. Moldflow Insight also has advanced customisation of the process including the ability to select the moulding machine, specify valve gates, adjust mould materials, solve for a Design of Experiments (DOE) or parametric study and much more.