& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

CAM stands for computer-aided manufacturing. Computer-aided manufacturing (CAM) software helps people create programmes for various CNC machines to support different manufacturing processes. These include milling, turning, turn-mill, cutting, probing, part inspection, additive manufacturing and more.

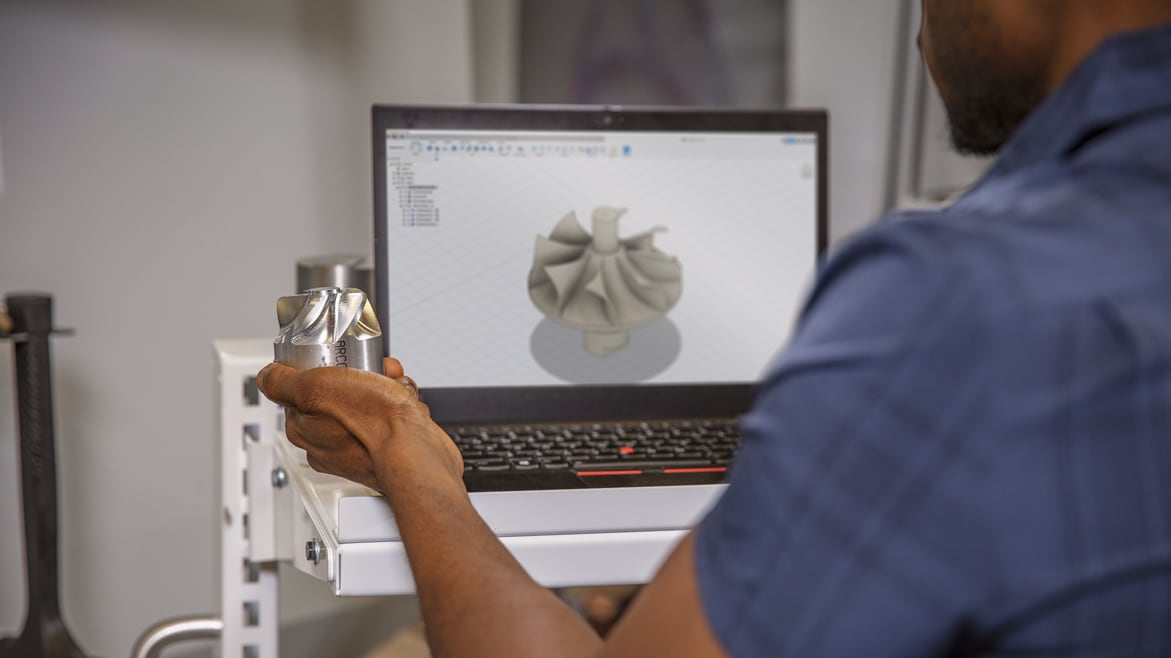

CAD stands for computer-aided design. Much like CAM, CAD uses computational power and software to help designers create more complex and capable designs than they could have by hand. CAD and CAM are different. CAD helps designers create digital representations called 3D models while CAM helps write code to drive CNC machines that create physical parts.

CAM unlocks tonnes of automation and powerful capabilities that simply wouldn’t be possible using conversational or handwritten NC code. High-efficiency roughing toolpaths use algorithms that require computers to calculate. Creating toolpaths for complex geometry can be near impossible to do by hand, making CAM software necessary.

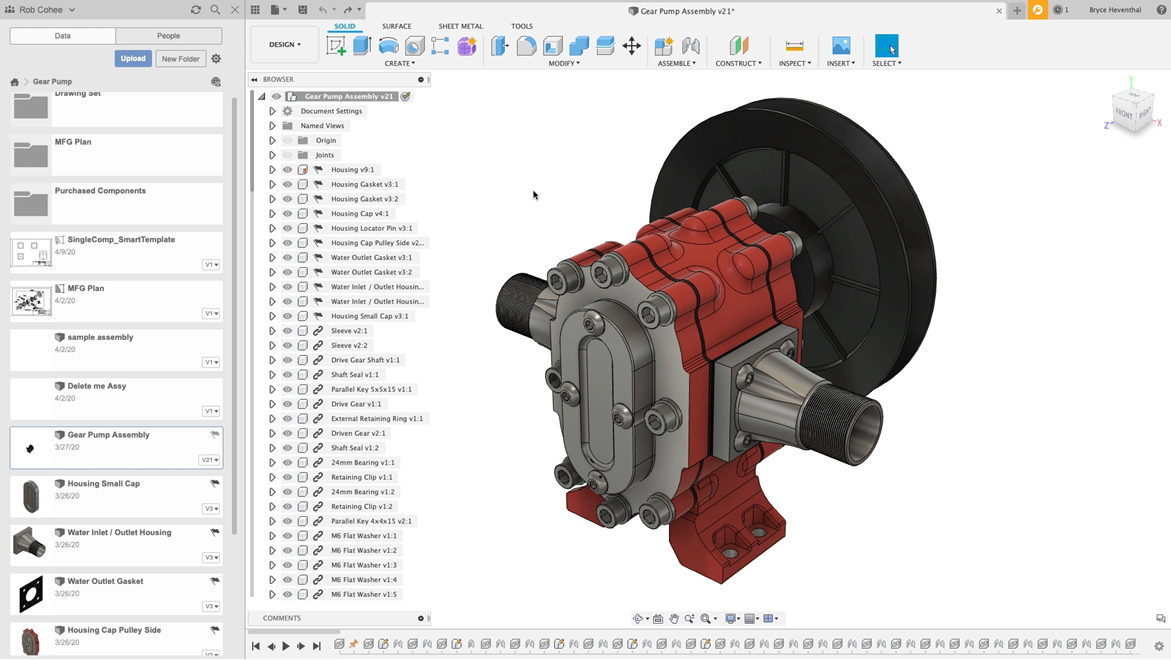

Fusion 360 (US site) includes a full suite of CAM tools and toolpaths to support many processes including milling, turning, cutting and additive manufacturing. Fusion 360 integrates CAD, engineering, documentation and collaboration tools directly with CAM to improve workflows and address the entire product development process.

From high-strength billet machined parts to the mould and die used to produce fibreglass shells for a wide range of car bodies.

Whether it’s sheet metal fabrication (US site) or bringing castings within tolerance, CAM software is used widely in industrial machinery.

Both additive and subtractive manufacturing are used to make dental implants, prosthesis and even joint replacement parts.

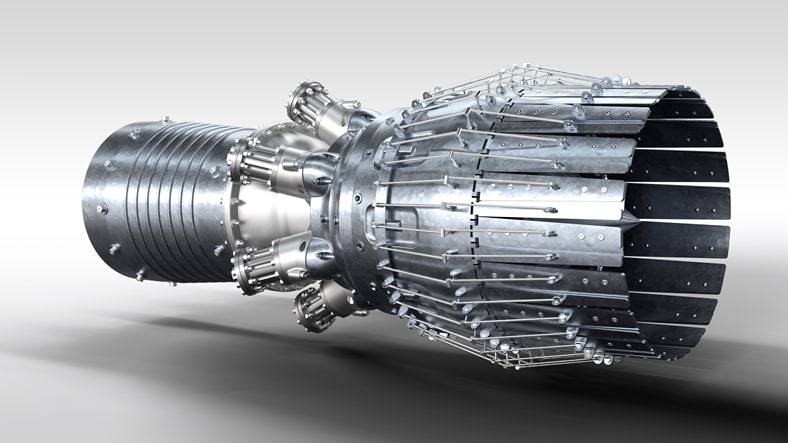

Aerospace requires CAM to make high-strength, tight tolerance parts (US site) where billet machined aluminium and titanium are common.

Often called machining, this process removes material from an initial block or casting of stock to make the final product. This process often uses mills, lathes or more complex machines.

Additive manufacturing is the process of creating parts by depositing material. There are many specific processes under the umbrella of additive manufacturing (US Site), but all require CAM software.

Once toolpaths have been created, CAM software creates the NC code (US Site) used to drive the CNC machine. Code tailored to a specific machine can take advantage of special configurations and options.

Make quality parts faster with truly integrated 3D CAD/CAM software for machinists.

Make complex parts quickly and accurately at a fraction of the cost of similar solutions.

Collaborate with shared tool libraries, post processors, custom defaults and more, syncing best practices across your team.

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication and metals-based additive manufacturing.

Learn what Computer Aided Manufacturing (CAM) is and how it uses toolpaths, G-code and CNC machines to turn 3D CAD models into products.

Dives into the benefits of integrated, cloud CAD + CAM software, including collaboration, automation and organisation.

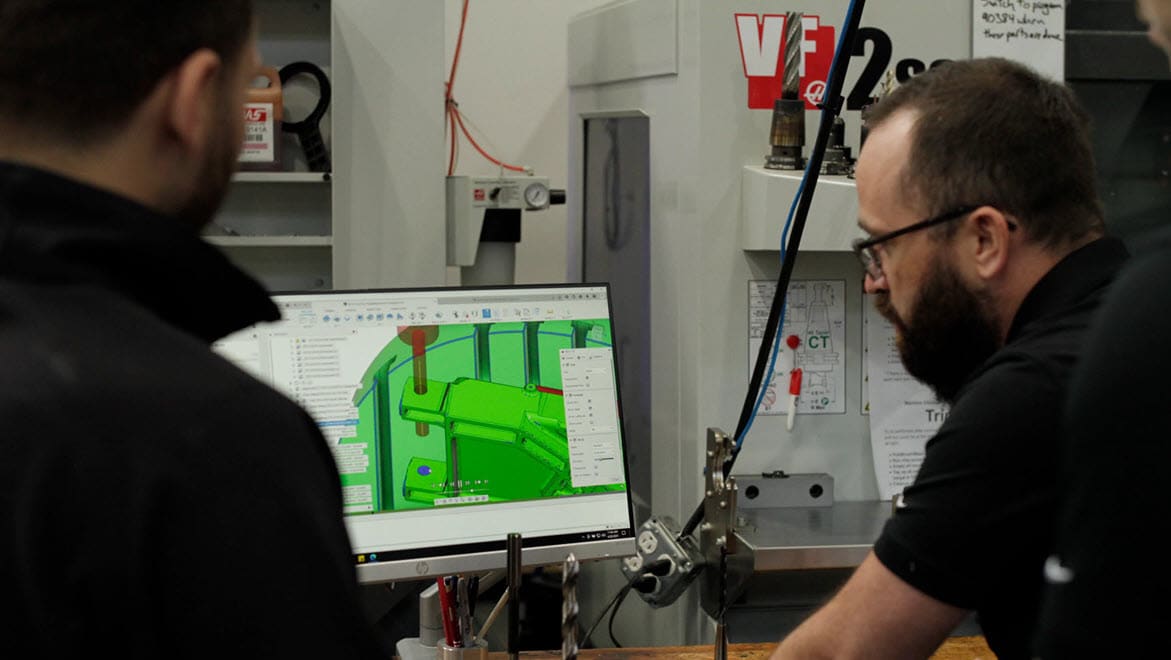

Identify the key daily challenges machine shops face and how integrated CAD/CAM software like Fusion 360 can solve them.

Learn about how Autodesk Fusion 360, a cloud-based, integrated CAD/CAM software, can transform your design process.

Learn how to use the CAM workspace inside Fusion 360 to go from a design model to a programmed part that is ready for manufacture.

View video tutorials on how to get started with CAM in Autodesk Fusion 360.

Find answers to frequently asked questions about CAM CNC software.

CAM software (US Site) is used to create a set of instructions for different machines. Often these instructions are in the form of G code or a similar coding language that tells the machine what to do, where to go and how to get there. This language is not very friendly to humans and CAM software acts as a mediator between how humans work and how a machine receives instructions. This basic framework can apply to a variety of applications, including milling, turning, mill/turning, Swiss machining, fabrication, robotics and additive manufacturing.

The cost of CAM software can vary greatly. Entry level packages may be affordable. It's common for specialised CAM software to climb to the cost of £19680 or more. Legacy CAM software also has maintenance fees required to receive yearly updates. Other hidden costs like post processors apply to most CAM packages, to allow use with the CNC machine. Fusion 360 offers a low cost but comprehensive alternative, starting at £1574 /year for access to our entire manufacturing portfolio. There are no additional maintenance costs and there's a library of fully customisable post processors for free.

Generally, computer-aided manufacturing software is used to create toolpaths. These aptly named operations define the path the cutting tool will take while removing or adding material. Specific parameters like cutting speed, spindle speed, type of motion, stepover, stepdown and more are defined in the CAM software to fit the user's specific application, which the computer uses to generate the actual toolpath. Then the post processor translates the toolpath data into NC code that the machine can understand.

CAM software has several advantages over handwritten code or conversational (at the control) programming. First, complex toolpaths that would be impossible to write by hand can be created using CAM software. This includes complex tool motion found in high efficiency roughing toolpaths that leverage high computation algorithms or complex tool motion created from complex part geometry. CAM software like Fusion 360 is associative to the CAD model, so changes to the model automatically update the toolpath, saving time and reducing rework. CAM also allows programmes to be created while a job is running on the machine, increasing overall productivity.

Yes, Fusion 360 can generate G-code for many CNC machines thanks to its large library of post processors. G-code (US Site) is a language that many CNC machines use to operate and how programmers and operators feed instructions to the machine. While it may seem antiquated, generating G-code is an important part of the programming workflow for the large majority of machinists today.

Yes, Fusion 360 includes a full suite of CAM software to program a variety of CNC machines. Fusion 360 manufacturing has a modern interface and helpful tips built in to make programming easy to learn and CAM easy to use. It’s a great low-cost option to start automating your machining and programming processes.