& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

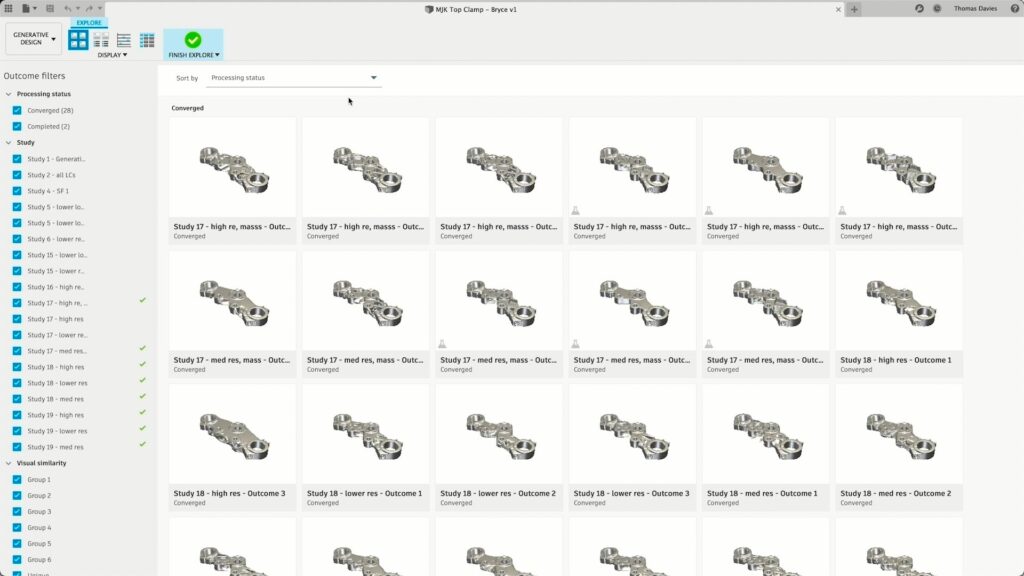

Generative design for manufacturing is a design process that uses artificial intelligence (AI) and cloud computing to quickly generate a wide range of design alternatives based on defined parameters, such as materials, manufacturing methods and performance requirements.

The AI tests each potential design against the defined parameters to find the best solution. This approach can result in innovative designs, efficient use of materials and significant time savings, as it automates much of the trial-and-error work traditionally done by human designers.

Quickly identify solutions to minimise mass and material use while maintaining performance standards, meeting design goals and respecting engineering constraints.

Evaluate multiple manufacturing methods using generative design and discover solutions to improve and optimise product durability and eliminate areas of weakness.

Explore a range of design solutions that allow you to consolidate multiple components into solid parts, reducing assembly costs and simplifying your supply chain.

Explore a range of design solutions that allow you to consolidate multiple components into solid parts, reducing assembly costs and simplifying your supply chain.

Autodesk is a pioneer in the generative design space. Autodesk Fusion allows designers and engineers to input design goals and parameters, and the software generates a number of design alternatives that meet these criteria. The designer can then select the most appropriate design based on their specific needs.

Autodesk's generative design tools (US Site) are used across a range of industries, including automotive, architecture and manufacturing. They help in optimising product designs, improving efficiency, fostering innovation and reducing costs. By using Autodesk's generative design tools, manufacturers and designers can explore a vast range of design alternatives, enabling them to make more informed decisions and produce better outcomes.

Generative design in Fusion gives you the ability to select multiple manufacturing methods to quickly explore numerous solutions for your design and engineering challenges.

Generative design allows manufacturers to input design goals, constraints and parameters, and then automatically generates a wide range of design alternatives. This feature significantly accelerates the design process, enabling manufacturers to explore more innovative and efficient designs in a fraction of the time it would take manually.

Generative design optimises the use of materials by creating lightweight yet strong structures. This is particularly beneficial for reducing material costs and improving sustainability by minimising waste and reducing the overall carbon footprint of the manufacturing process.

The ability to specify performance criteria, such as strength, stiffness and flow properties, allows generative design to produce solutions that meet or exceed the required performance standards. This ensures that the resulting designs are not only manufacturable but also perform optimally under real-world conditions.

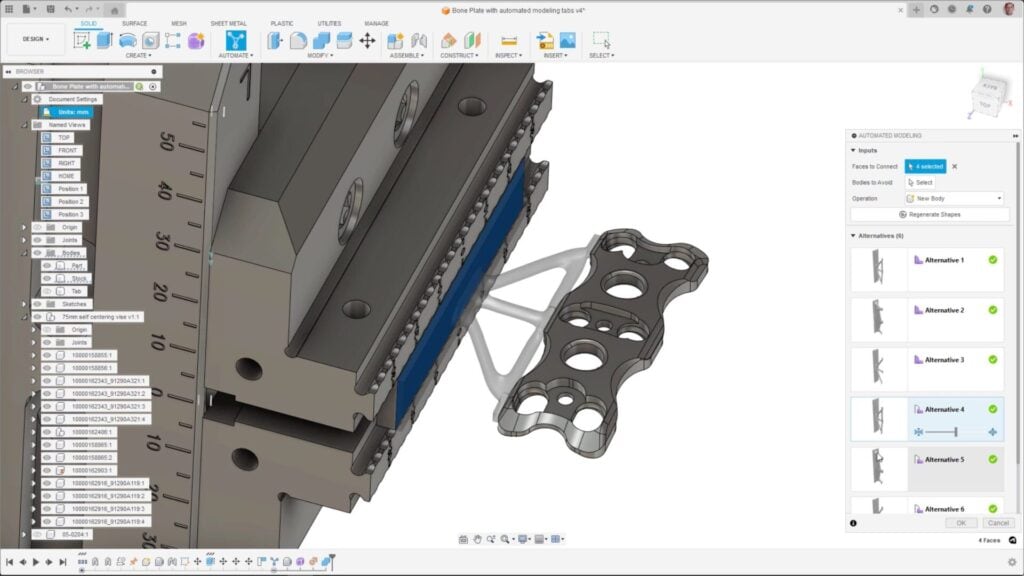

Fusion's generative design is well-integrated with advanced manufacturing techniques such as additive manufacturing (3D printing) and CNC machining. This ensures that designs generated are theoretically optimal and practical to produce using the latest manufacturing technologies, leading to faster prototyping and production cycles.

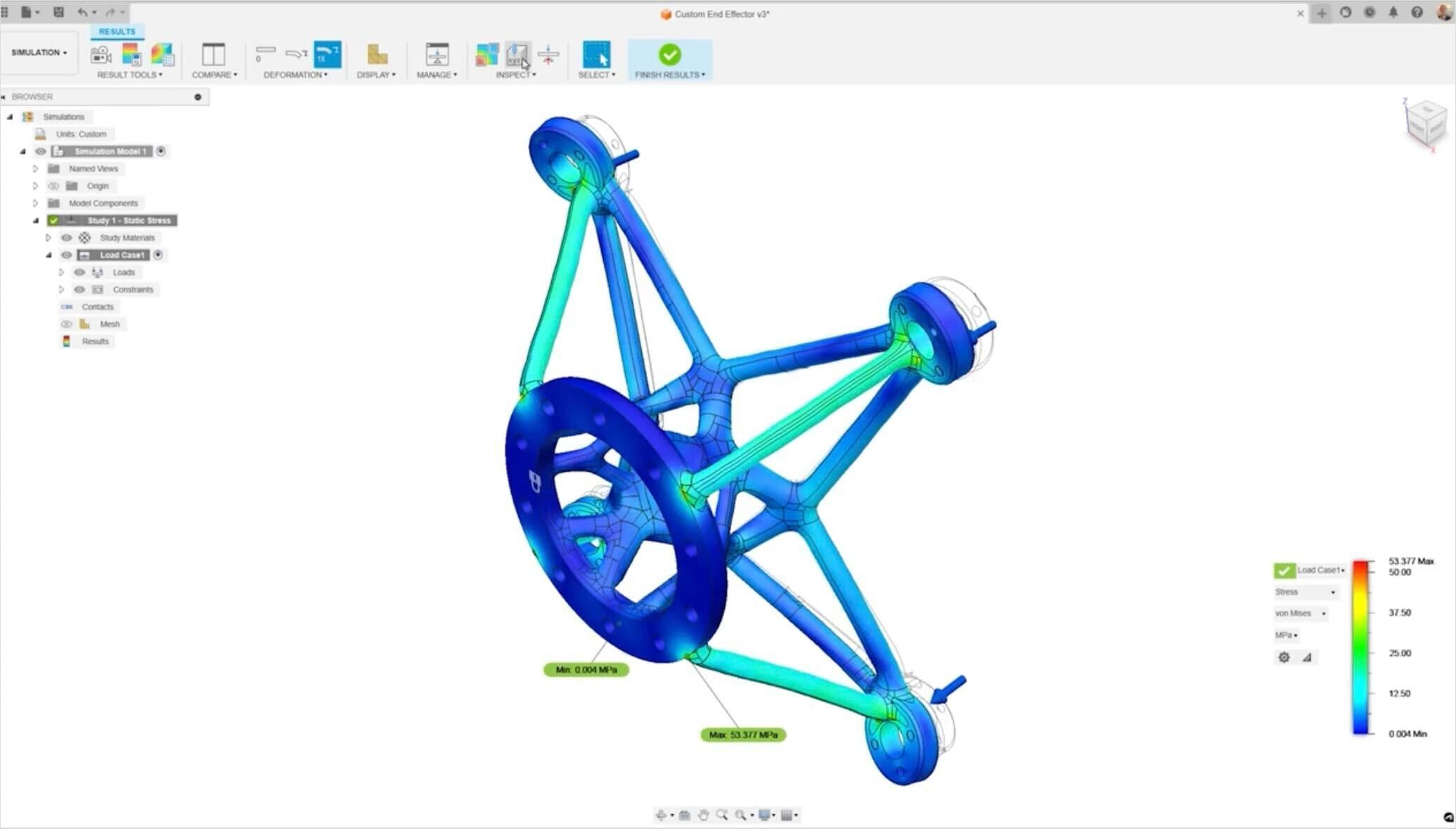

Optimise part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection moulding and more.

The Autodesk Fusion Simulation Extension empowers your team to analyse part performance, manufacturability and generative design capabilities.

Generative design outcomes can help you discover weight reduction and performance enhancements. Combine this with simulation study types such as structural, thermal and explicit simulations, as well as injection moulding, to gain a comprehensive understanding of how your 3D design will perform under real-life conditions before manufacturing.

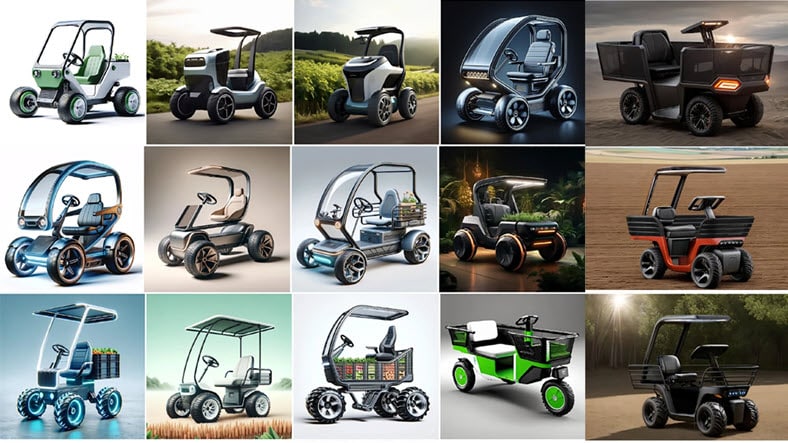

See how generative AI expanded the design possibilities for a unique Yamaha EV prototype rugged enough to tackle mountainous, agricultural terrain.

Image courtesty of Yamaha EV

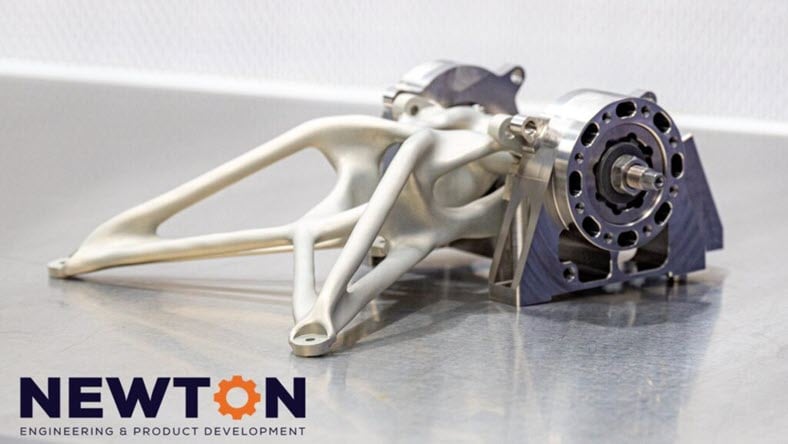

Learn how Newton | Engineering and Product Development are supporting the Mars Sample Return with a lid designed using generative design in Autodesk Fusion.

Image courtesy of Newton Engineering and Product Development

See how a joint effort between top aviation companies and universities yielded a metal 3D-printed turbine centre designed with generative design in Autodesk Fusion.

Image courtesy of GE Aerospace

Here are five tips to consider when editing generative design studies, from the Smooth command to the Zebra Analysis tool.

The value of Fusion generative design and manufacturing capabilities to engineers goes well beyond the current generation of existing CAM systems. Let’s take a look at eight reasons why.

Generative design in Fusion goes beyond running studies. Explore how to easily edit parts, run simulations and more.

Generative design is revolutionising various stages in the manufacturing process. Here are some common applications:

Generative design is an innovative computer-aided design process wherein software, powered by artificial intelligence, is used to create multiple optimised design solutions based on specific input criteria.

Here's how it works:

1. Defining Design Goals: The process begins when a designer or engineer defines the parameters or constraints of the design problem, such as the desired performance, budget, materials, manufacturing methods and physical constraints.

2. Algorithmic Generation: The software then uses these constraints to generate a multitude of design alternatives that satisfy the requirements. It uses advanced algorithms and artificial intelligence to explore all the possible permutations of a solution.

3. Evaluation and Iteration: The software evaluates the generated designs against the set criteria and ranks them. The designer or engineer can then review the outcomes, adjust the constraints or requirements if needed, and repeat the process until an optimal design solution is found.

4. Final Selection: The final design is selected from these optimised solutions based on its performance, cost and feasibility for manufacturing.

Generative design is widely considered to be the next frontier in computer-aided design. It harnesses the power of AI to develop high-performance and highly sophisticated design iterations that help solve complex challenges, like reducing component weight, optimising performance and making designs simpler.

Autodesk Fusion is a powerful and versatile tool for generative design. It offers a range of features for design, simulation and fabrication in a single, cloud-based platform.

Generative design is a powerful tool, but it also comes with certain challenges and limitations. Here are a few of the most common ones:

Generative design is significantly influencing the process of product development in various ways:

1. Increased Design Efficiency: By generating multiple design solutions that meet specific criteria in a short amount of time, generative design speeds up the design process. Designers can evaluate a broad range of options quickly and focus on refining the most promising ones.

2. Optimisation of Designs: Generative design uses algorithms and AI to optimise designs based on set parameters like weight, strength, cost and more. This leads to high-performing, efficient and innovative products that may not have been conceivable through traditional design methods.

3. Material Efficiency: Generative design can provide solutions that use less material but still maintain the required strength and performance. This not only reduces cost but also supports sustainability goals.

4. Enhanced Customisation: Generative design allows for a higher level of customisation in product development. It can generate designs tailored to specific needs or customer preferences, opening the door to personalised products on a larger scale.

5. Integration with Advanced Manufacturing: Generative design is often used in conjunction with additive manufacturing (3D printing) processes. The complex and organic shapes that generative design algorithms often produce are well-suited to these manufacturing methods, which can create shapes that are impossible with traditional manufacturing techniques.

6. Reduced Time to Market: By accelerating the design process and improving the integration between design and manufacturing, generative design can help companies get their products to market faster.

7. Risk Mitigation: By exploring a wide design space and testing various scenarios digitally, generative design can help identify potential design issues early, reducing risk and cost in the product