Keyboard ALT + g to toggle grid overlay

Replacement of Coal Fired Boilers

The South African Department of Public Works and Infrastructure (DPWI) services several governmental entities which include the Department of Correctional Services, the South African Police Service, and the Department of Justice, to name a few.

When maintenance or new capital infrastructure is needed, the DPWI is brought on board to assess the requirements and make a recommendation to outsource service or do it in-house. DPWI is essentially the “Handy Man” of the State.

Although most major projects are outsourced, the DPWI now has the necessary skills to operate on a level playing field with many of its contractors. With the implementation of Autodesk software, most notably AutoCAD and Revit, the department can facilitate projects when there is a need to execute quickly.

The result is a department that will be able to save millions of Rands across various projects by utilizing their in-house experts.

The Challenge

A challenge presented itself at the Westville Prison in Durban when a boiler broke down, forcing one boiler to continuously produce steam, see Figure 2. The DPWI management and engineers put their heads together and called for an urgent replacement of the boilers.

The steam generation system in any prison is a critical function for the operation of that prison. When two of the Westville Prison’s boilers broke down, the DPWI had to take swift action to rectify the situation.

Investigations carried out by the mechanical engineering team deduced that the prison requires approximately 10 000 kg/hr of steam. As a result of leaking condensate pipelines, only 20% of the condensate returned to the boiler house.

The in-house mechanical engineering team worked tirelessly on the design and model of the boilers, and the pipework in the boiler house. The design included three coal-fired boilers that generate steam at 10 000 kg/hr and operate at a pressure of 700 kPa.

“We had two options to resolve this problem, we could use a consultant on this project but that process is time-consuming and costly, or we could run this project in-house,” says Michael Tladi, Directorate: Mechanical Engineering at the DPWI. “We chose the latter and that turned out to be a major cost- and time-saver for us.”

In fact, the DPWI saved R14 million in consultant fees and managed to optimize the time it took to complete this design by around 60%. Tladi confirmed that, with Autodesk’s specialized MEP toolsets within AutoCAD and Revit, the Department was able to produce higher-quality designs than ever done before.

Figure 2 Boilers to be replaced

Acting CIO, Bheki Zwane, was instrumental in driving the business case for investing in the Autodesk software with the support of Modena Design Centres who managed the training and issuing of licenses to the Department's architects and engineers.

—Jay Moolman, General Manager, Modena Design Centres-AEC, South Africa

Bringing the project in-house

"Apart from the cost and time savings, there are numerous other benefits that come from generating AutoCAD drawings and 3D models in-house," says Thuthuka Mbhele, Project Director at the DPWI.

“The fact is that our budgets at the DPWI are at times subject to being reprioritized due to external events or factors we can’t control within the Department,” says Mbhele. “But the reality for us is that we still need to carry on maintaining infrastructure.”

Mbhele adds that if the DPWI can save money by managing certain projects themselves, it will become the norm going forward. “If your mechanic does not know how the engine works, there is no way he can fix it,” he adds.

“This is the biggest problem with government infrastructure at the moment, we rely heavily on external providers and consultants so when maintenance time comes, our own facilities maintenance managers don’t really understand how the infrastructure works," says Mbhele.

"These detailed drawings that the DPWI can now produce are self-explanatory and our managers will know how everything works," says Mbhele. “This is incredibly valuable for maintenance at a later stage as owning and understanding the drawings allows us to upskill our own engineers.”

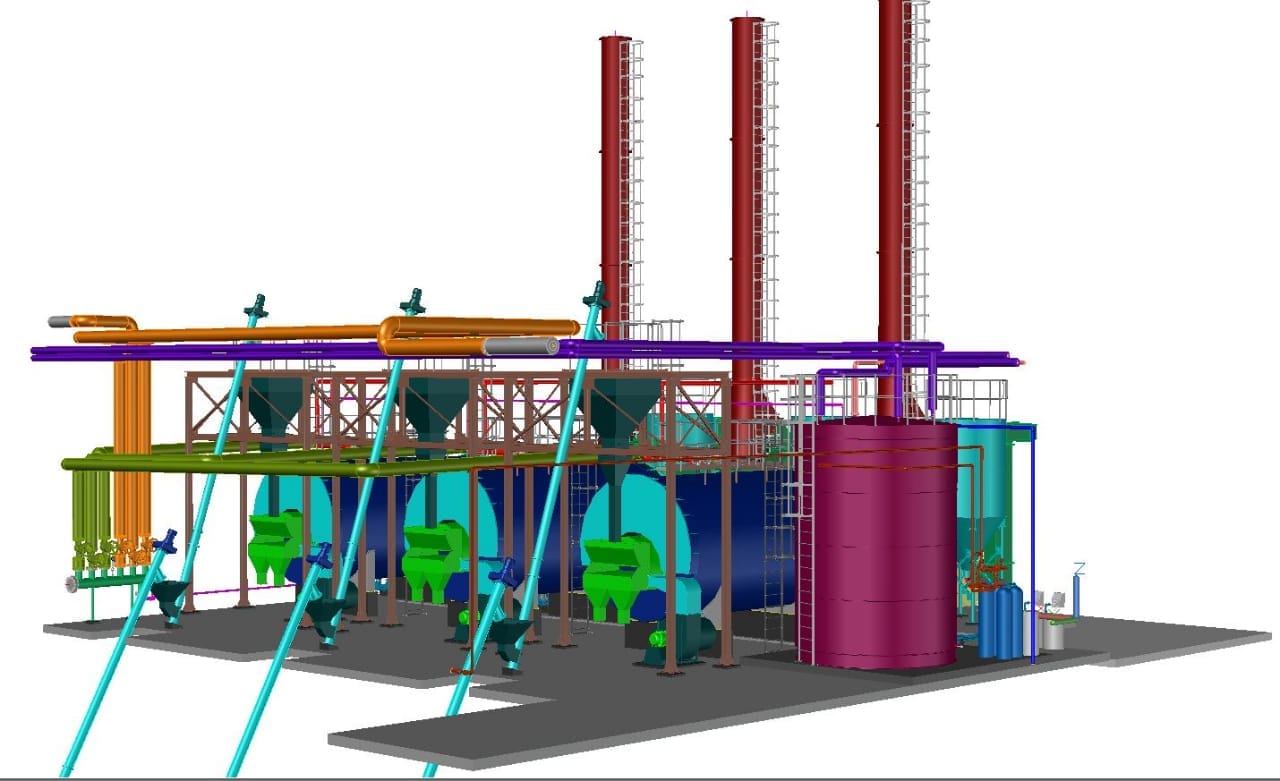

Figure 3 below is a conceptual layout of the boiler house, allowed the engineers to build on their ideas and improve their design of the boiler house. The client was also presented with a clear idea of what to expect and was kept well informed about the designs throughout the stages of the project.

Figure 3 Conceptual layout of the boiler house and the boilers with ancillary equipment

In-house engineers deliver a DPWI first

Using Autodesk software, the DPWI has been able to upskill its engineers and continually push the benchmark for service delivery. The 3D model generated in AutoCAD, refer to Figure 4, is an example of the skills used by DPWI for service delivery.

“As the DPWI we have historically never produced 3D models but our work on Autodesk software has allowed us to go further in understanding more about the visualizing of equipment before it is installed on-site,” adds Tladi.

These 3D models make it easier for all the stakeholders on a project to easily identify what needs to be done while keeping the technology in-house and saving the department millions of Rands in fees.

Figure 4 3D model of the boilers and steam piping in the boiler house with the smokestack in the back

Autodesk Software Improved Workflow

Amina Ismail, a junior mechanical engineer with the Department of Public Works, who worked closely with Dietter Treto Gonzalez (Cuban Technical Advisor – Mechanical Engineer), found that her team saved a lot of time using Revit and the MEP toolsets within AutoCAD.

Ismail says, “With models being in 3D we could quickly and easily generate a lot of various views of any portion of the design.”

She adds that the drawings they produced were more detailed and accurate, making it much easier to collaborate with other engineers to get the project done timeously.

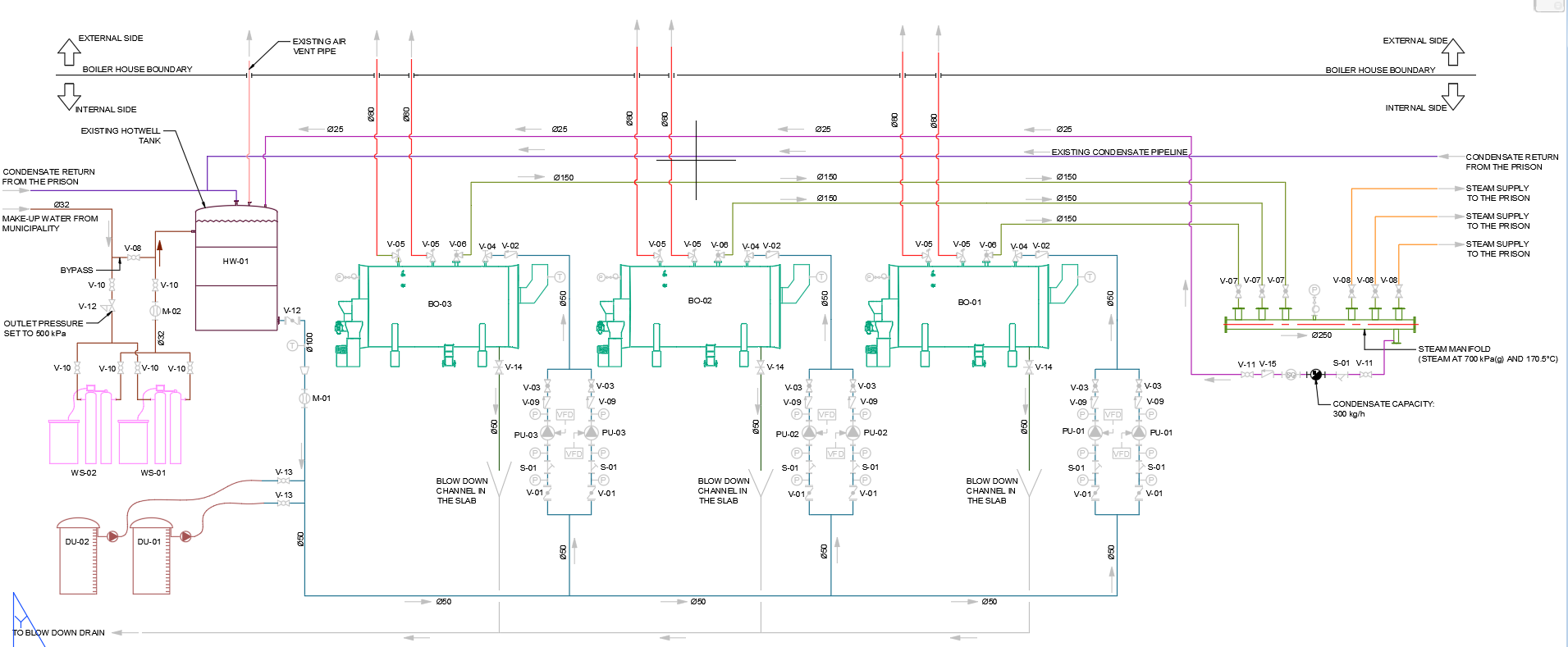

The team also had to design a steam manifold to manage the steam supply to the prison, refer to Figure 5. AutoCAD was used to generate multiple layouts of the boilers and the boiler ancillary equipment.

Figure 5 Details of steam manifold

AutoCAD was also used to develop the process flow and instrument diagram to show the relationship between the equipment and steam generators as shown in Figure 6. "Blocks were created for the equipment to be used in the system, these blocks were then placed along the steam or condensate pipelines," says Ismail.

Figure 6 Process and equipment flow diagram

Support Partners to the rescue

Ismail adds that this incredible achievement would not have been possible without the support and training provided by Modena Design Centres, an Autodesk Gold Partner. “Having support on hand to help us with the software proved hugely time-saving and an important part of our project success.”

Now that the DPWI has the capability to own the raw data to its various infrastructure projects, the cost savings could be huge with future projects, something that has not been possible before.

"On this project alone, the DPWI saved a year in time alone," adds Thuthuka. "We also used this project to great success in the mentoring of our junior engineers using Autodesk technology throughout the process."