説明

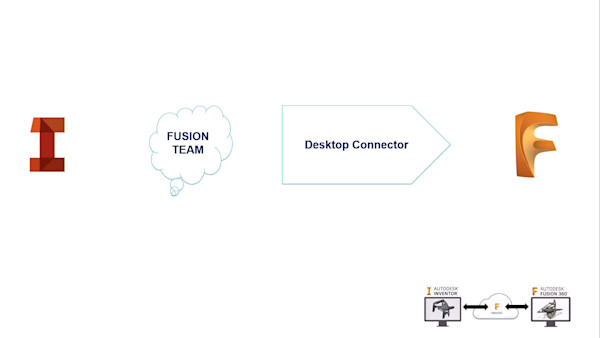

Grumpy Sloth, a boutique mechanical keyboard startup in New Zealand, set about designing and manufacturing its own keyboard from the ground up, including a custom PCB (printed circuit board). With initial concepts laid out in Autodesk Fusion 360 software, the company went on to create and detail the product model in Inventor software, managing the design with Vault software—all while using the available connections through to Autodesk Fusion 360 for developing the PCB, and manufacturing the rest of the components in the Autodesk Fusion 360 manufacturing workspace.

主な学習内容

- Learn why you would want to use Inventor as your primary design tool, but Autodesk Fusion 360 for electronics design and manufacturing.

- Learn how to apply simple iLogic rules to make use of iCopy functionality in Inventor.

- Learn how to integrate Autodesk Fusion 360 into your Inventor workflows while still maintaining associativity.

- Learn how to create a PCB in Autodesk Fusion 360, driven from Inventor geometry, then include the PCB in your final Inventor assembly design.

Downloads

このクラスが好きな人はこんなも好きです

Instructional Demo

Access Granular Design Data Using GraphQL in Autodesk Platform Services

Industry Talk

Sharing Fusion 360 Files Through to Vault

Industry Talk

Fusion Lifecycle and Vault: The Synergy

Instructional Demo

AnyCAD and the Exchangeability of Inventor

Instructional Demo