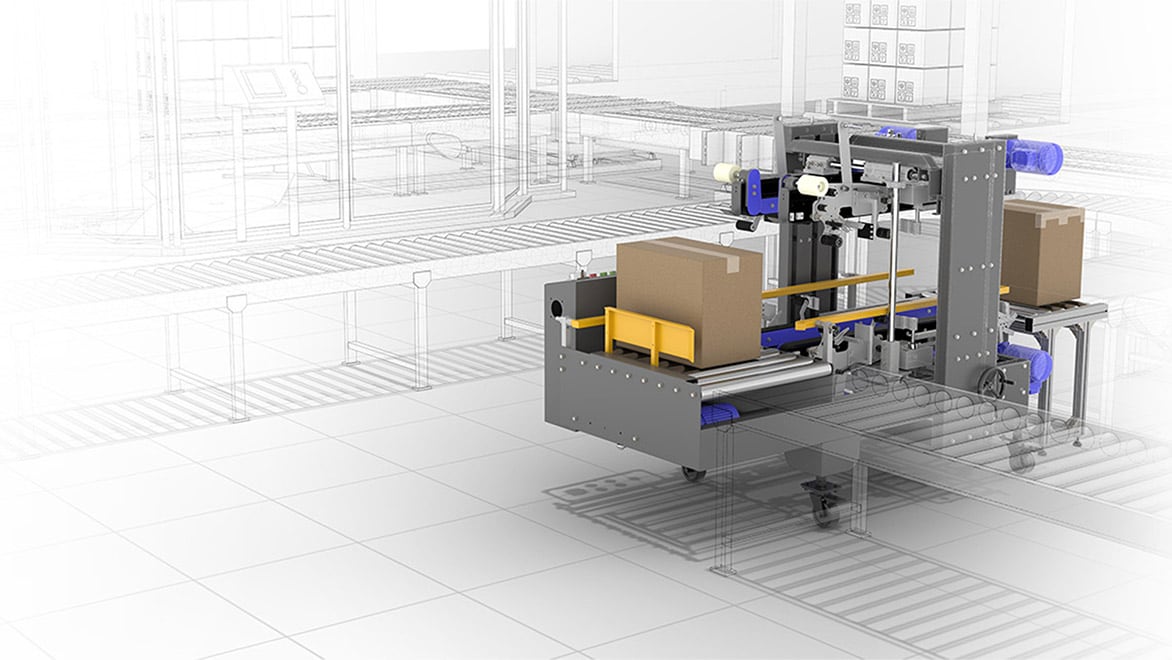

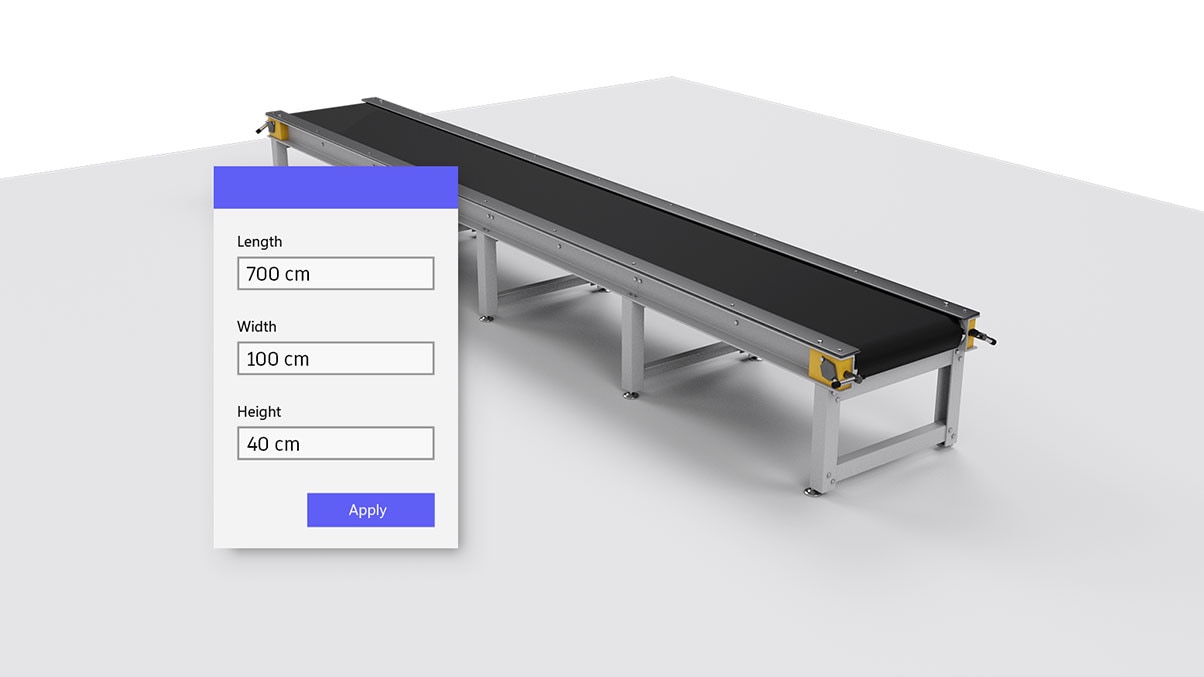

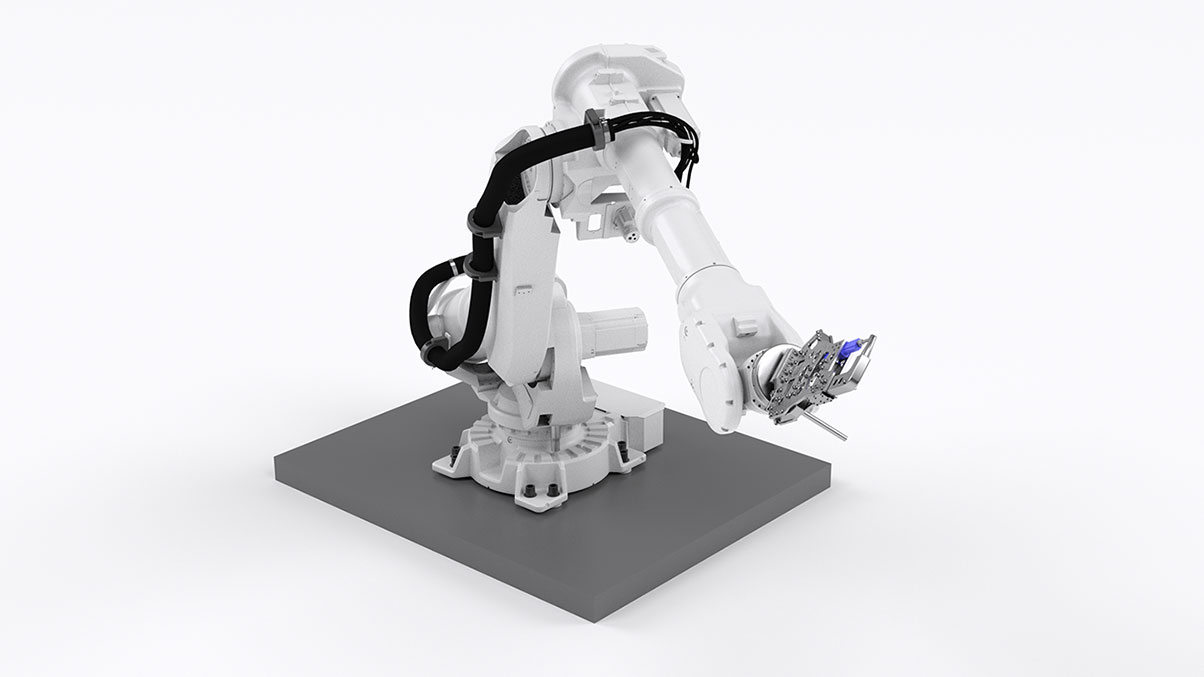

Achieve better outcomes for your products, businesses, and the world with intuitive, powerful, and accessible technology that connects every detail of your design and make process.

Autodesk empowers innovators to create smarter, more reliable industrial machinery for their customers.