& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

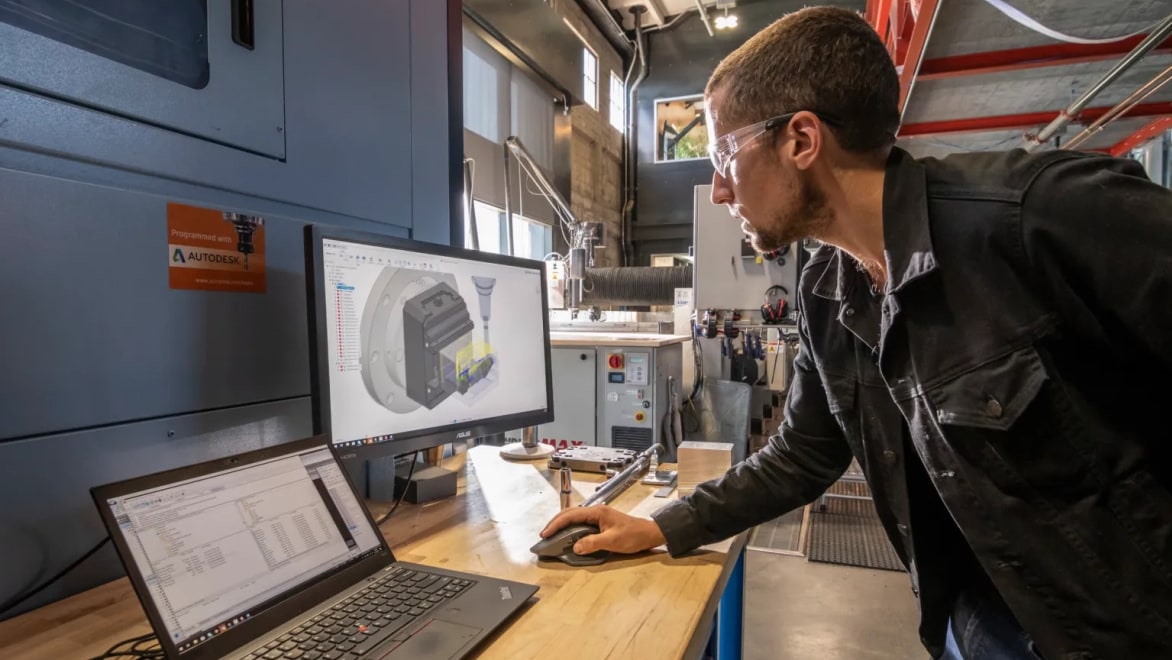

Professional CAD/CAM tools built on Inventor and AutoCAD

Computer-aided engineering (CAE) (US Site) is the use of computer software to aid in the design, analysis and manufacturing of products. It encompasses functionalities like simulation, optimisation and validation, combined with disciplines like finite element analysis (FEA), computational fluid dynamics (CFD) and multiphysics for enhanced engineering analysis.

Computer-Aided Engineering (CAE) software is a type of program that uses advanced computational methods to assist in engineering tasks. It includes several disciplines including stress analysis on components and assemblies, kinematics, mechanics of materials and optimisation of designs. CAE software enhances the engineering process by providing tools for modelling, simulation, validation and optimisation of products and manufacturing tools. It allows engineers to evaluate and improve product designs, ensuring their functionality, durability and efficiency.

Access advanced simulation study types to validate real-world design performance through side-by-side design comparisons.

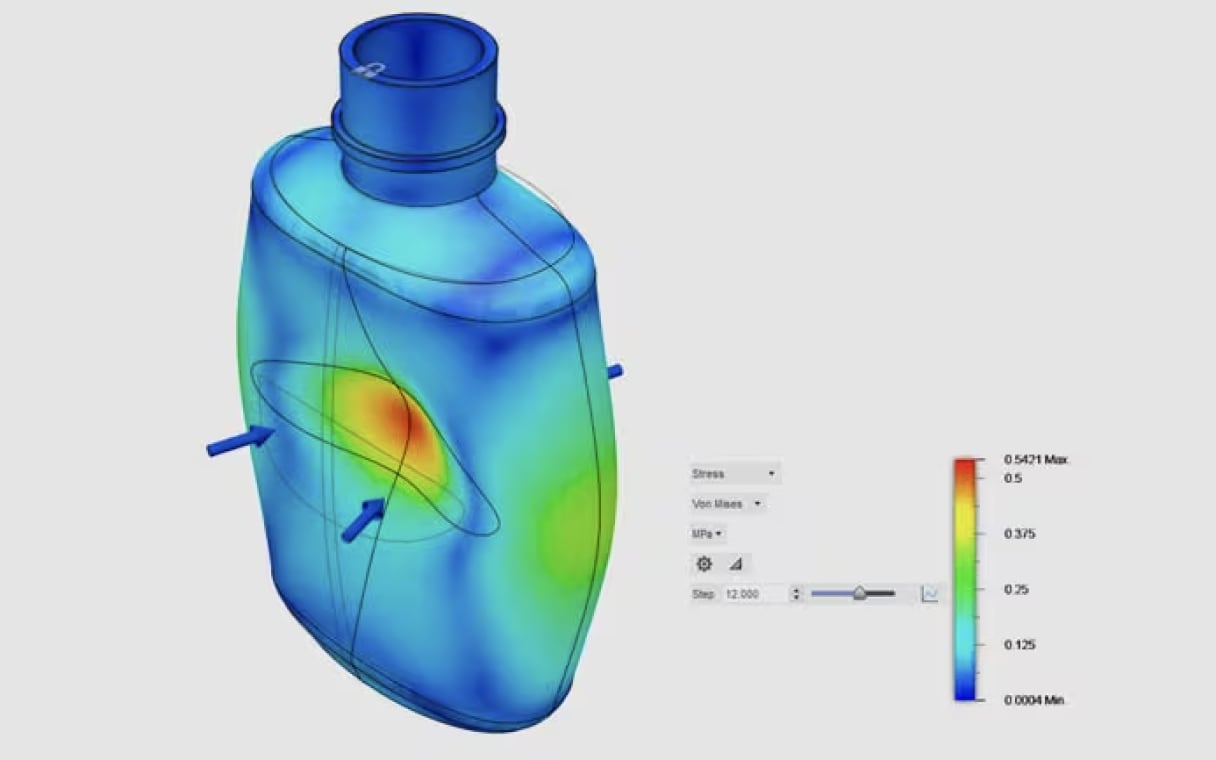

By simulating real-world conditions, CAE tools enable the prediction and improvement of product performance and reliability before manufacturing, ensuring optimal product functionality.

CAE software allows virtual prototyping, reducing the need for costly and time-consuming physical prototypes, and speeding up the product development cycle.

Computer-Aided Engineering (CAE) is widely used to simulate real-world conditions, optimise designs and validate product performance, enhancing the overall engineering process.

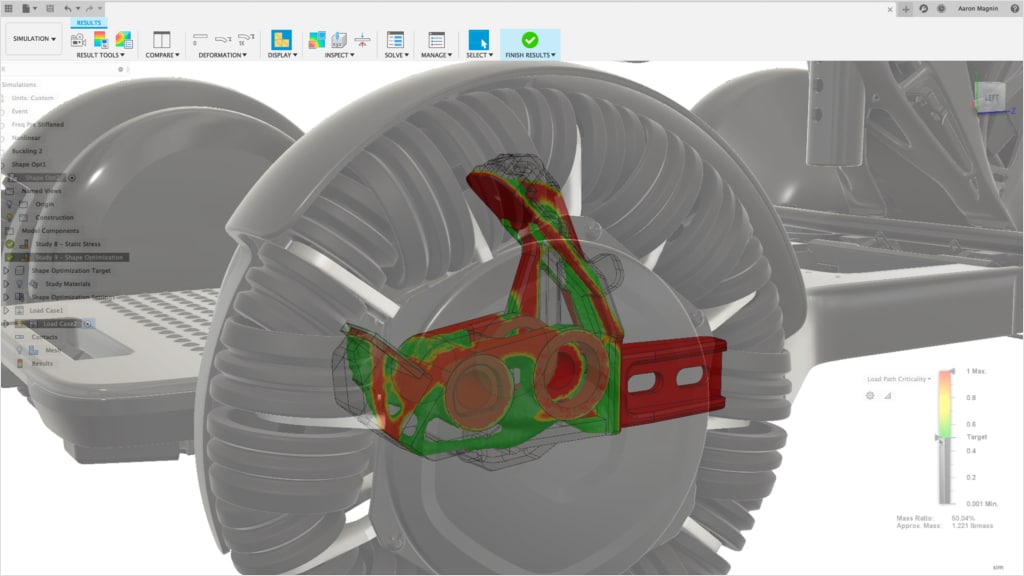

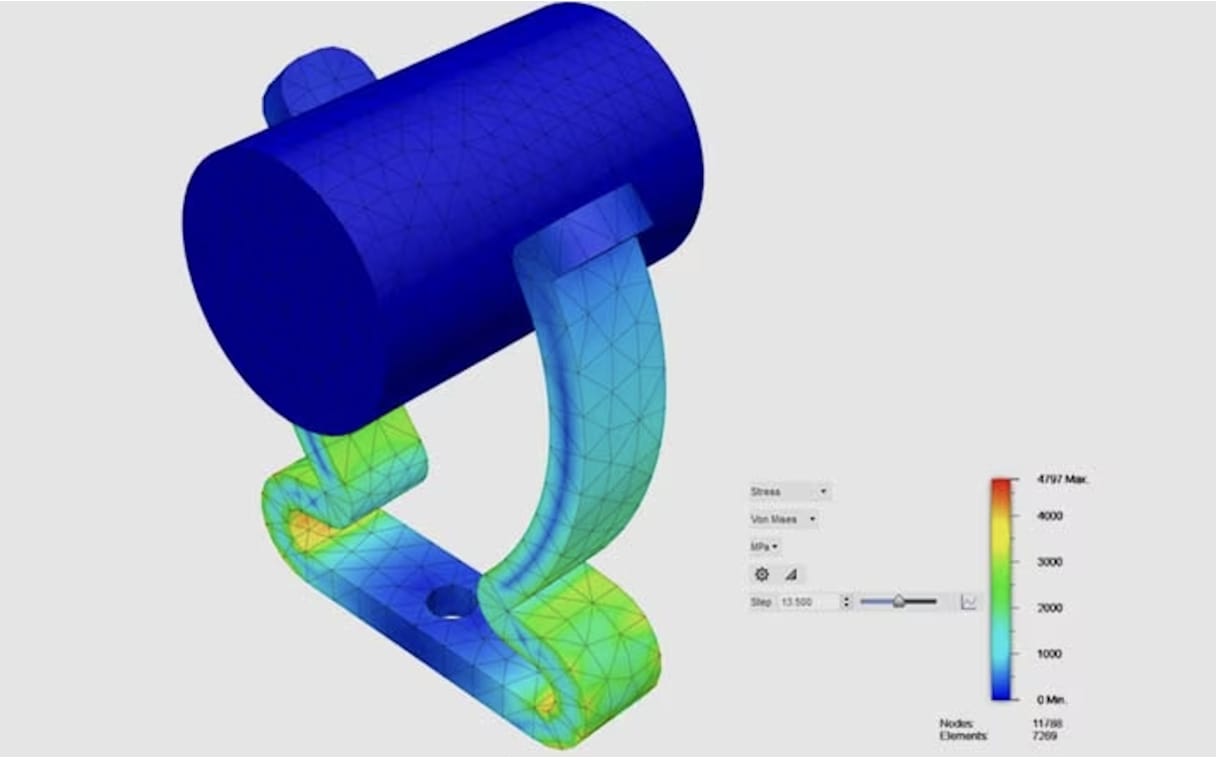

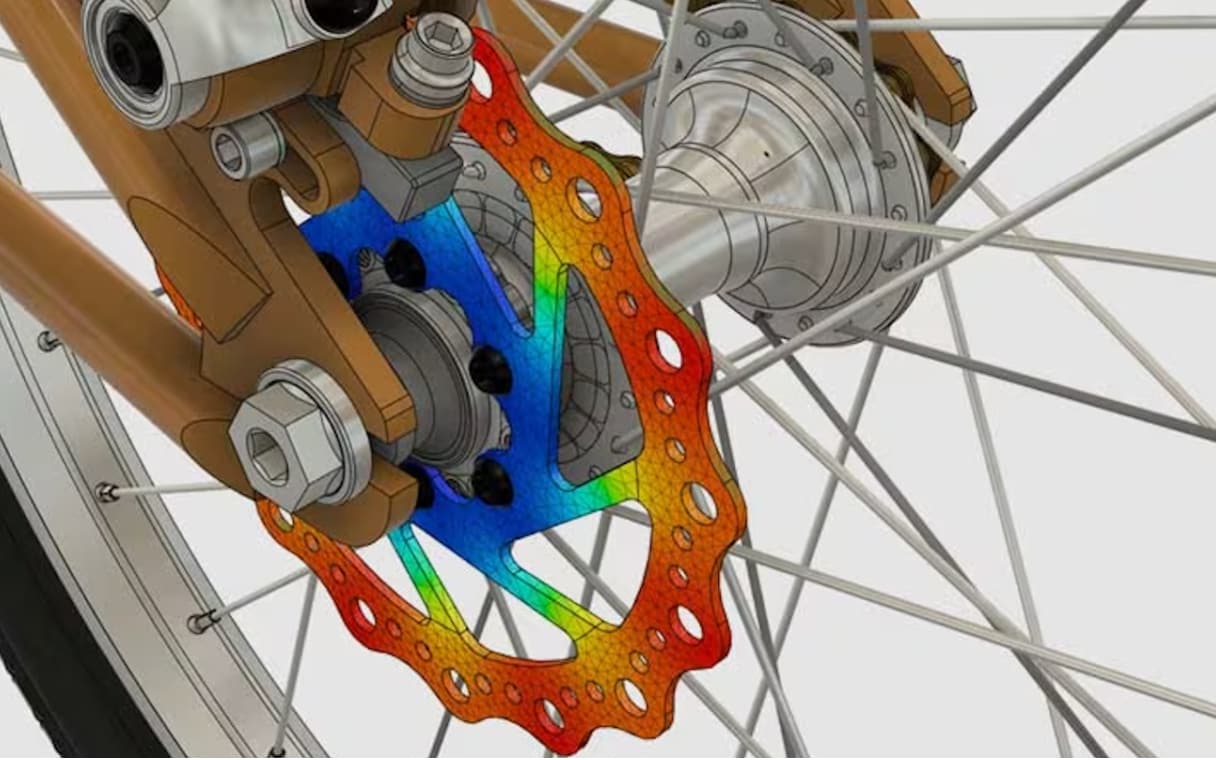

Using Finite Element Analysis (FEA), CAE can simulate and predict how a product will respond to physical forces like tension, compression and shear. This helps engineers optimise and validate their designs to ensure durability and reliability.

In Computational Fluid Dynamics (CFD), CAE helps simulate fluid flow, heat transfer and other related phenomena inside or around a product. This is crucial in fields like aerodynamics, hydraulics and HVAC systems where fluid behaviour significantly impacts product performance.

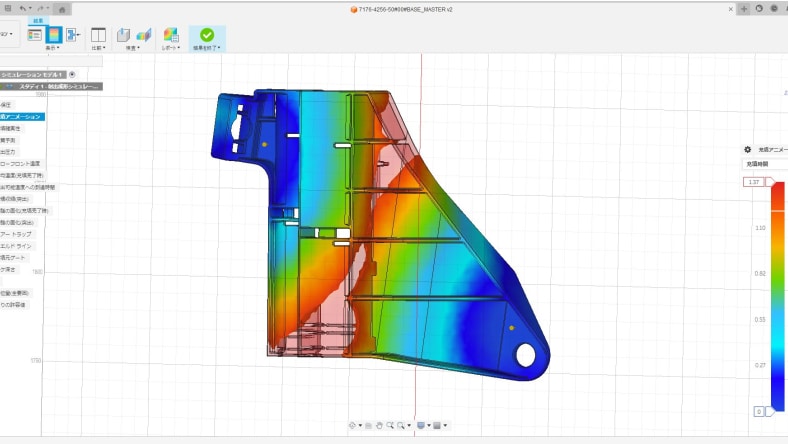

CAE can perform thermal analysis to predict how heat transfer will affect a product. This helps make sure the product can maintain effective performance under varying temperature conditions. This is particularly critical in the electronics, automotive and aerospace industries.

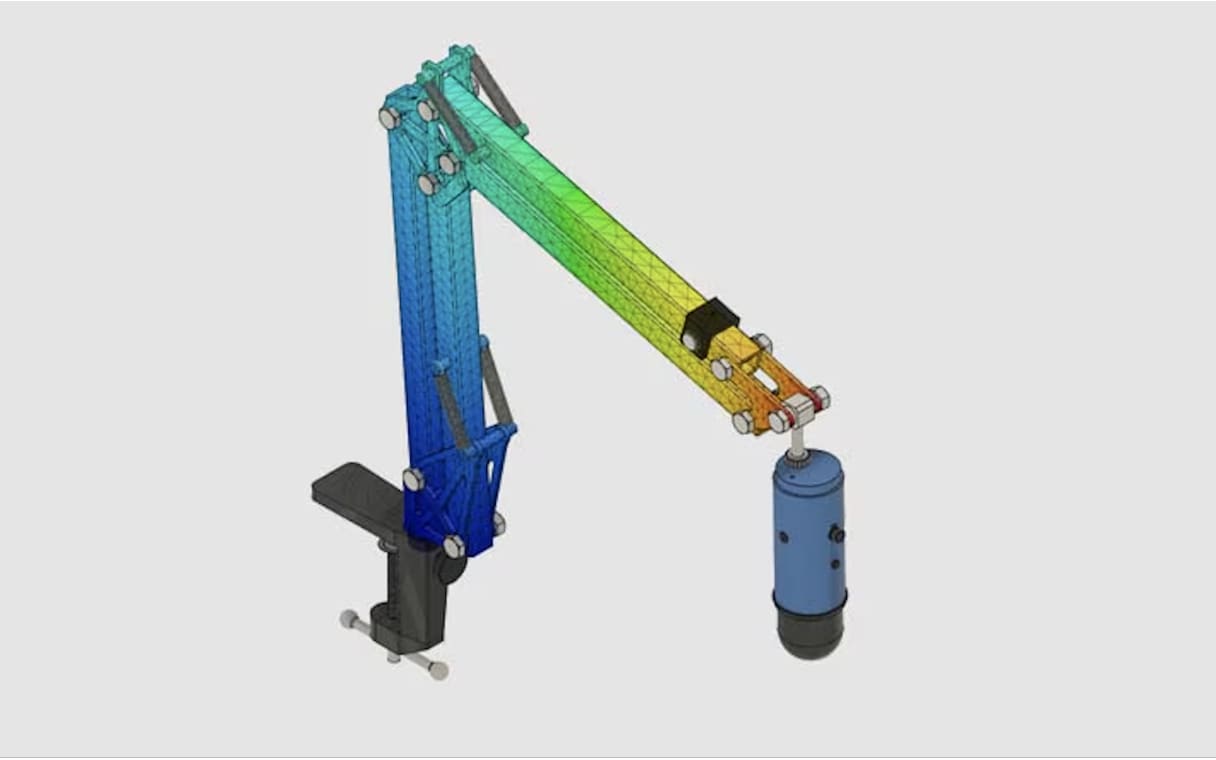

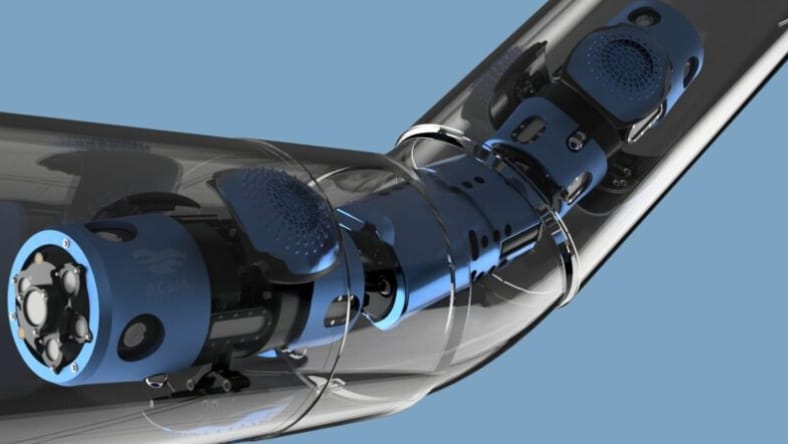

CAE is used to simulate and analyse the dynamic behaviour of systems with multiple components. This helps engineers understand the impact of motions and forces on the assembly. This is crucial in designing complex mechanical systems like vehicles, robots and machinery.

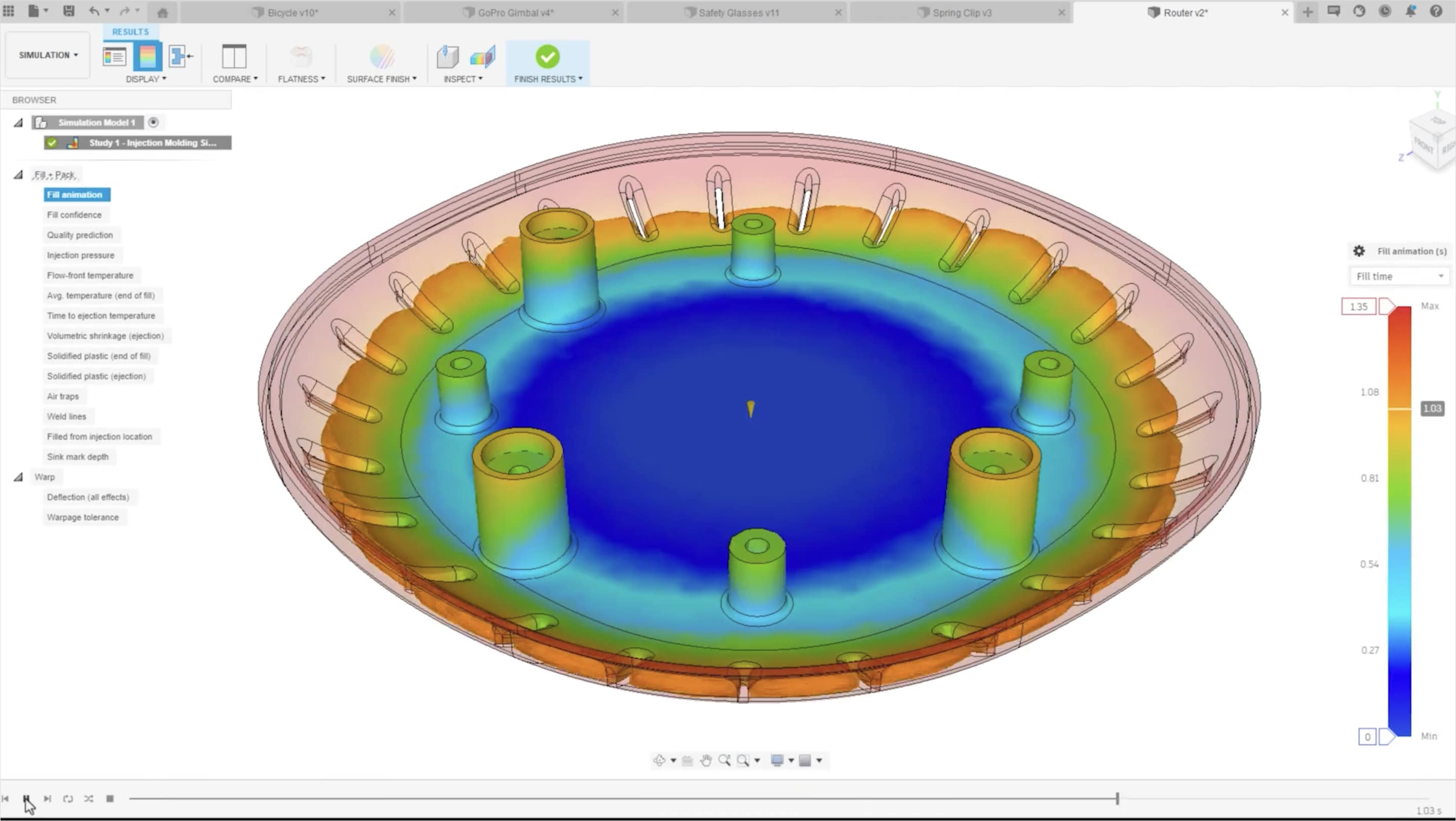

Optimise part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection moulding and more.

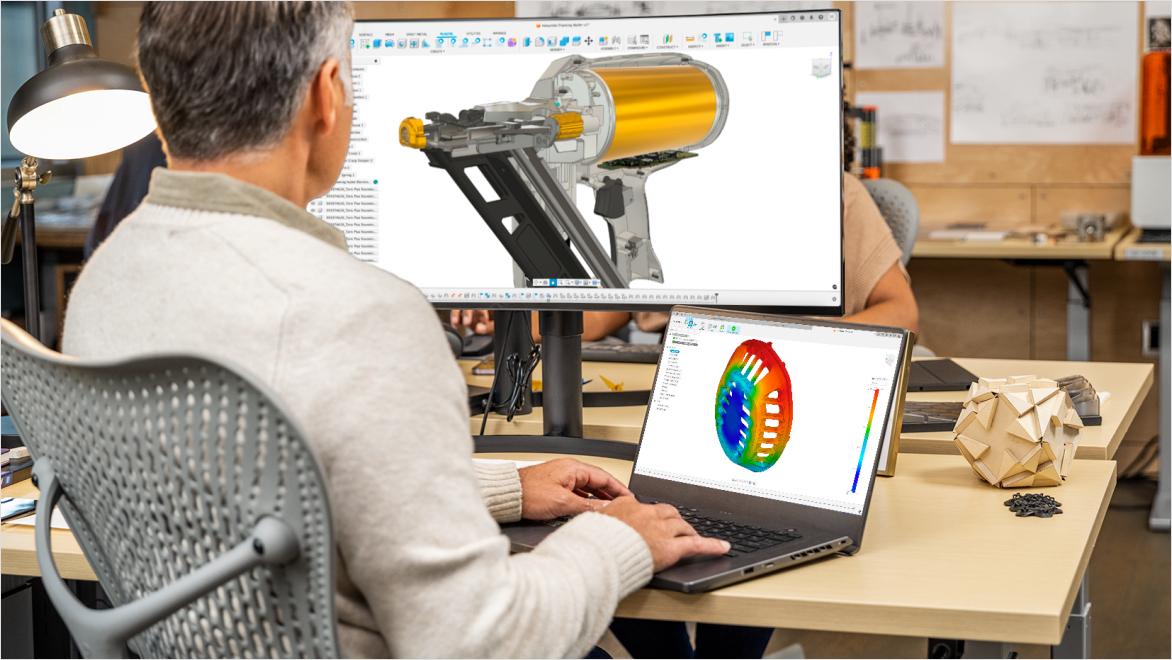

The Autodesk Fusion Simulation Extension, including Computer-Aided Engineering (CAE), equips your team to analyse part performance, manufacturability and generative design capabilities.

Generative design outcomes can guide you to achieve weight reduction and performance enhancements. By combining this with various simulation study types like structural, thermal and explicit simulations, as well as injection moulding, you can acquire a comprehensive understanding of how your 3D design will perform under real-life conditions before manufacturing.

Dive into the limitless design possibilities with Autodesk Fusion's CAE capabilities.

Automate performance and reduce design costs with generative design. Minimise physical prototypes with digital prototypes using simulation tools.

Access advanced simulation study types to validate real-world design performance through side-by-side design comparisons

Use manufacturing-process-aware artificial intelligence to quickly expand design options well beyond human imagination.

With the ability to simulate large deformations, motion and contact behaviours on nonlinear materials, this CAE capability is pivotal in predicting how materials and structures will respond under diverse stress conditions, thus enhancing design reliability.

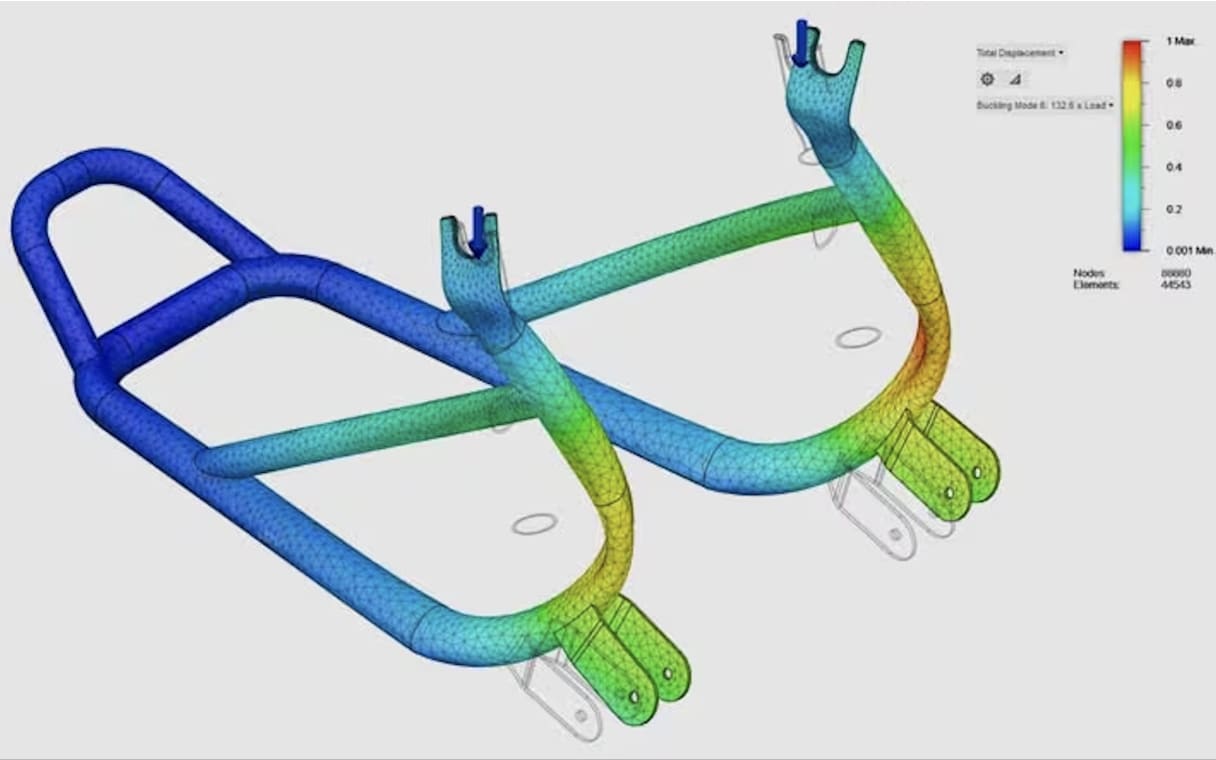

This CAE feature offers critical insights on potential structural failure due to buckling. By simulating how structures react under various loads, designers can refine their designs and mitigate risks associated with structural instability.

By predicting how time-dependent forces influence 3D design performance, this CAE capability enables designers to anticipate and mitigate potential issues, thereby improving product reliability and lifespan.

This feature allows designers to analyse the effects of natural vibrations on parts or assemblies. Understanding these resonant frequencies is crucial in CAE to prevent potential structural failure and optimise design.

This feature allows designers to simulate heat transfer and temperature-induced stresses. It's crucial for understanding how temperature changes affect system performance, aiding in the design of thermally efficient and reliable systems.

Bringing consumer products to market faster requires a smooth transition from design to production. With Autodesk Fusion, product designers have the ability to use CAE analysis tools, which were created with the designer in mind, to validate the product performance and quality before manufacturing.

Kawai Plastic Industry used the Fusion Simulation Extension, a Computer-Aided Engineering (CAE) tool, to run injection moulding simulations and flow analyses. This allowed them to prevent short shots in their process, visually confirm mould accuracy and reduce the number of trial injection runs by 25%, significantly improving their cost efficiency.

Dr. Hannes Schwenke used Computer-Aided Engineering (CAE) in the form of 3D modelling and printing technologies. Using Autodesk Fusion and Netfabb, precise 3D models of artery systems and brain aneurysms were created. These models helped in visualising complex surgical procedures, improving surgeon training and enhancing patient treatment outcomes.

Coral Maker utilised Computer-Aided Engineering (CAE) through Autodesk Fusion to design and prototype moulds for mass manufacturing coral skeletons. They also used it to test robotics systems for seeding corals. This CAE tool facilitated iterative design improvements, and enabled the use of CNC machines and 3D printing for manufacturing.

Discover how ACWA-ROBOTICS uses Autodesk Fusion to design water pipe-inspecting robots. The article underscores the significance of Computer-Aided Engineering (CAE), particularly simulations for assessing mechanical durability and thermal characteristics. These CAE features in Fusion are crucial to successfully designing and optimising the robot's performance.

Get started with CAE with these informational blog posts.

In product development, Computer-Aided Engineering (CAE) swiftly validates designs before manufacturing, reducing costs, time-to-market and enhancing product quality.

This article expands upon CAD, CAM and CAE, advantages across crucial touchpoints in the end-to-end product development process.

Explore the world of Computer Aided Engineering (CAE), highlighting its crucial role in modern product development.

Discover how Autodesk Fusion revolutionises product development with its powerful CAE capabilities, seamless simulation and innovative digital prototyping in a robust cloud-based environment.

Here are some factors to consider when choosing a CAE software solution and a breakdown on how Autodesk Fusion can help.

Product development uses CAE software like Fusion for rigorous testing and design enhancements under varied conditions.

Autodesk Fusion is unique as it integrates CAD, CAM and CAE in one platform, allowing for a seamless workflow from design to fabrication.

Autodesk Fusion's integrated CAE functionality significantly enhances the product development process by creating a seamless workflow from design to analysis. It allows engineers to perform various types of analyses like stress tests, fluid dynamics, thermal analysis and multibody dynamics directly on their CAD models without needing to switch between different software. This not only saves time but also ensures that the analyses are based on the most current model.

With the ability to quickly iterate designs based on these analyses, engineers can optimise their designs more efficiently, leading to improved product performance and reliability. Furthermore, this can greatly reduce the need for physical prototypes, saving both time and resources. Fusion's CAE tools also enable engineers to predict how the design will perform under real-world conditions, helping to identify and rectify potential issues early in the design process. This can significantly reduce the risk of product failure and the associated costs.

Fusion is a cloud-based platform, which means that it allows for real-time collaboration among team members regardless of their location. This is beneficial for CAE tasks, as it enables engineers to work together on the same design and simulation, facilitating the sharing of insights and speeding up the decision-making process. Team members can view, comment on and edit designs and simulations in real time, making sure everyone stays updated on the progress. Access to designs and simulations can also be controlled to maintain security and confidentiality.

Furthermore, Fusion allows for the sharing of CAE results with stakeholders who may not have a technical background. This can be done through visual reports and animations, making the data more understandable and aiding in communication. Overall, Fusion's CAE functionality significantly enhances collaboration among teams, leading to more efficient and effective product development.

Using CAE in Fusion allows for efficient design iterations, improved product performance, and reduced need for physical prototypes.

CAD (Computer-Aided Design) and CAE (Computer-Aided Engineering) are both software tools used by engineers, but they serve different purposes.

CAD (Computer-Aided Design) is used to create 2D/3D models and blueprints of products and structures. This software is primarily used by architects, engineers, drafters, artists and others to create precision drawings or technical illustrations.

CAE (Computer-Aided Engineering) is a term used to describe the procedure of using computers and software to assist with engineering tasks. It involves the use of computational tools that package together techniques for analysis, simulation, optimisation and manufacturing processes. CAE tools are used in stress analysis on components and subsystems, dynamics and impact analysis, kinematics and other physical simulations.

Autodesk Fusion is a comprehensive product development solution that combines CAD, CAM, CAE and PCB into one cloud-based solution.

While the accuracy depends on the input parameters, Fusion is generally considered reliable and accurate for predicting real-world scenarios using its advanced simulation capabilities.

Yes, Fusion allows for easy access and modification of old projects, making it convenient to iterate and improve on previous designs.

CAE software finds applications in a wide range of industries including automotive, aerospace, electronics, industrial design and many more where there's a need to understand or predict the performance of a product design or system.