& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Machine design companies must bring new designs to market in a competitive timescale, against headwinds of disruption in the supply of materials and components and the hiring (and retaining) of skilled labor. Digital transformation offers new opportunities–using connected and collaborative software, companies can increase agility to better respond to the fluctuating market.

Autodesk empowers industrial equipment manufacturers to create smarter, more reliable machinery with integrated solutions that streamline development processes and cover the entire design, validate, and manufacture lifecycle from concept to customer.

Create innovation capacity by streamlining everyday design and engineering tasks with automation. Integrated tools for machine design help you make well-informed decisions earlier during the design phase to accelerate your ideas and transform insights into smarter products and diversified offerings.

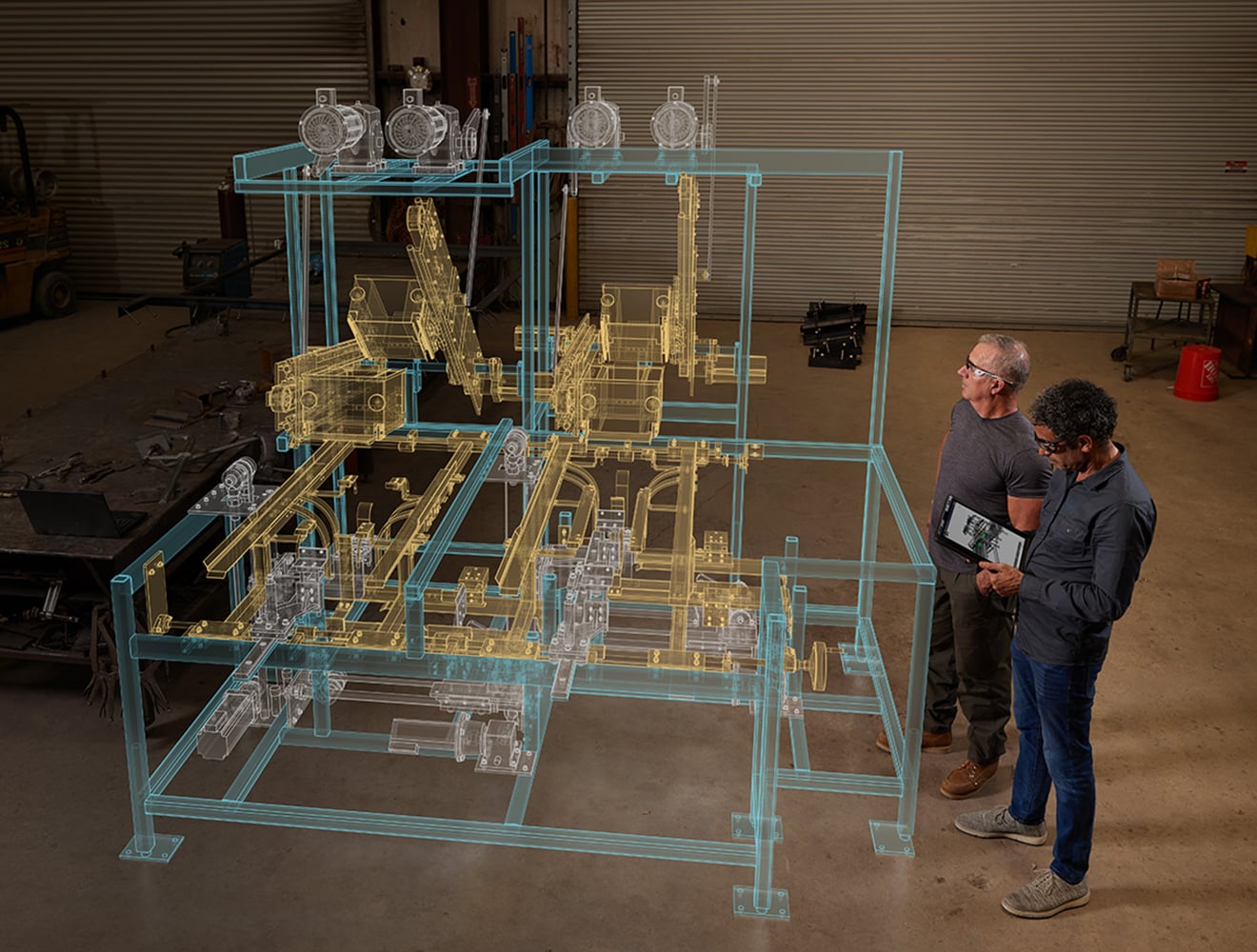

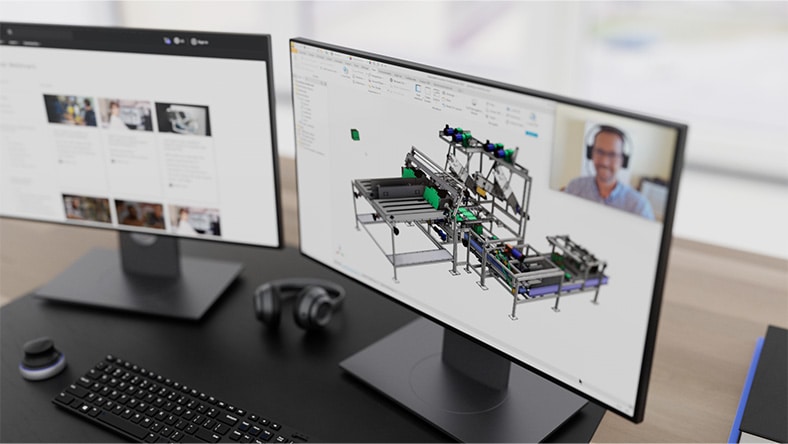

Seamlessly collaborate with your colleagues, clients, and supply chain using tools that connect your data and processes. Real-time access to reliable data helps reduce project risk and enhance decision making while fast-tracking machine designs from prototype to product.

Unlock the full potential of your industrial machine designs by implementing innovative solutions that increase manufacturing efficiency and flexibility. By integrating advanced CAM and additive technology, you can focus on better ways to make your products on time and on budget.

Get Inventor + AutoCAD + Autodesk Fusion + more—Professional-grade tools for product development and manufacturing planning.

Powerful product design and engineering tools for 3D mechanical design, simulation, visualization, and documentation.

2D and 3D CAD tools, with enhanced insights, AI-automations, and collaboration features. Subscription includes AutoCAD on desktop, web, mobile, and seven specialized toolsets.

Discover how industry leaders drive growth with AI-driven generative design and automation.

REPORT

Design and manufacturing experts are optimistic about the global landscape. In the latest State of Design & Make report, learn where manufacturers are investing to drive growth.

E-BOOK

Product data management (PDM) keeps teams organized during development, but adding PLM connects data, people, and processes, enhancing collaboration and control.

WEBINAR

Discover how automated workflows can streamline your design process and eliminate repetitive tasks that come with modeling standard features or configuring custom products.

BUYER'S GUIDE

Creating more innovative products and responding to customer needs quickly is key to accelerating growth. Learn how to select design software that delivers the capabilities you need.

Automate repetitive tasks. Capture and reuse engineering knowledge with a custom product configurator. Work more efficiently and create time to focus on innovation.

Secure and control your intellectual property. Collaborate with your internal and external colleagues. Manage and track decision-making to automatically maintain your audit trail.

Manage the many moving parts of your product lifecycle with PLM. Connect people, processes, and data to increase development agility and get to market faster.

Improve the performance of your industrial equipment with virtual testing before anything is sent to manufacturing. Predict, validate, and optimize your designs with accurate, trusted analysis.

Save time and money by avoiding high-precision tolerances that add unnecessary costs and effort to your CNC machining strategy. Stay on budget while ensuring the fit and function of your assembly design.

Exchange CAD data seamlessly, from virtually any source, while maintaining data integrity. Reduce wasted engineering time spent repairing translation errors and eliminate downstream problems.

Simplify and automate the creation of high-quality machine code while maximizing the use of your CNC machines. Put your design and manufacturing data at the center of everything you do to make more informed decisions.

Transform sheet and plate-based fabrication with automated nesting software. Save time with associative CAD/CAM tools that automate the flow from 3D design to 2D nests and automatically update when your designs change.

Minimize risk and maximize efficiency with specialized tools for production system and work cell design, from point cloud scanning and clash detection to production line simulation and installation sequencing.

Autodesk design and manufacturing solutions adapt to your needs with a wide range of capabilities that provide cross-discipline, cross-industry, interoperable workflows that support your processes.

Complete the form to talk to Autodesk Sales about solving your most challenging problems.

Image courtesy of Feige FILLING.

Industrial machinery is equipment used for processing, production, and distribution in industries such as energy, liquid & gas processing, mining, construction, agriculture, forestry, manufacturing, machine tools, industrial robots, and building services equipment.

Examples of industrial machinery include:

The different types of manufacturing equipment can be categorized by industry, process, size, or method of operation:

Software is used in the manufacturing industry for design, simulation, data management, process management, project management, inventory and supply chain management, quality and safety management, and the control and monitoring of machinery.