& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

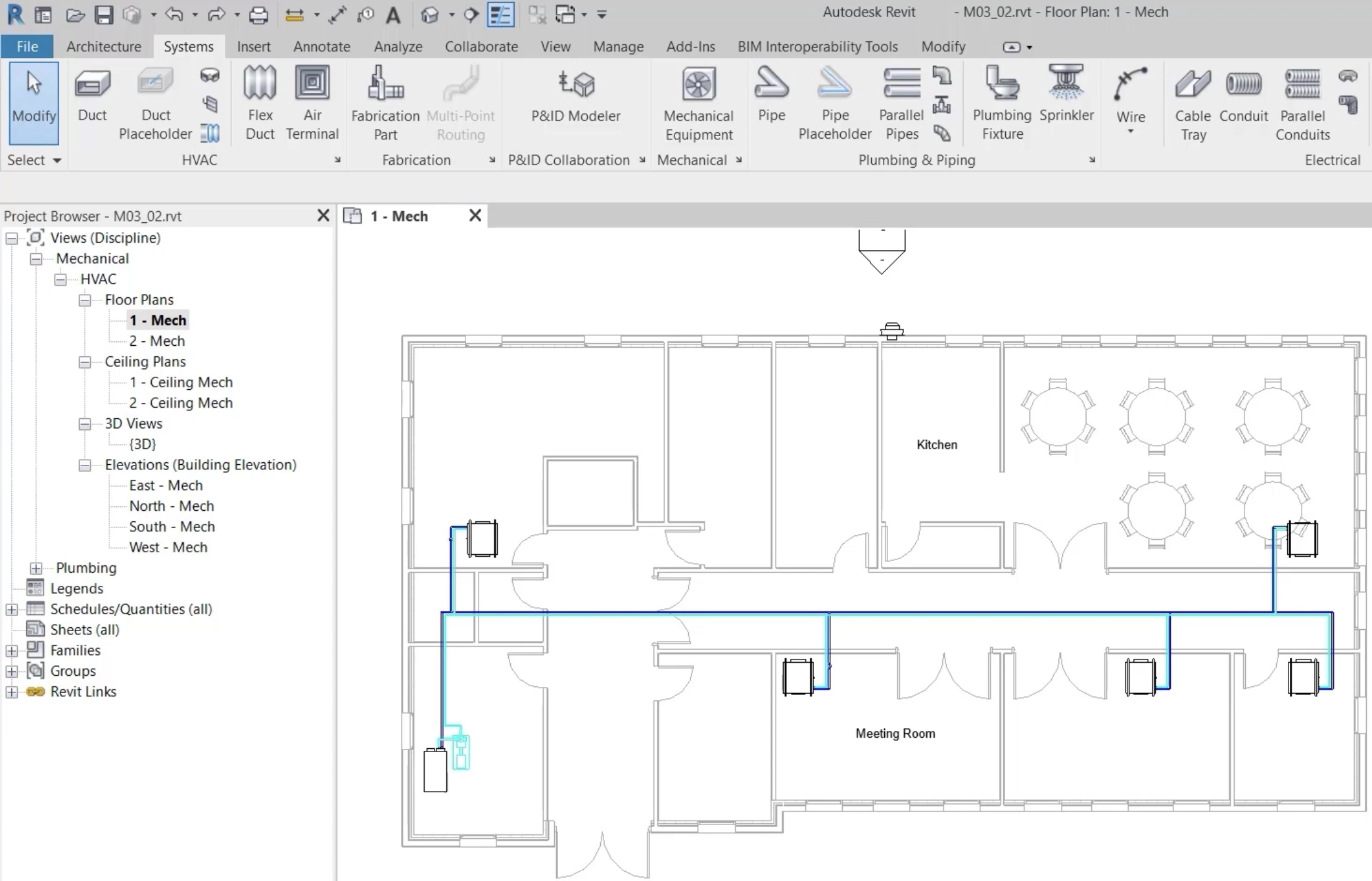

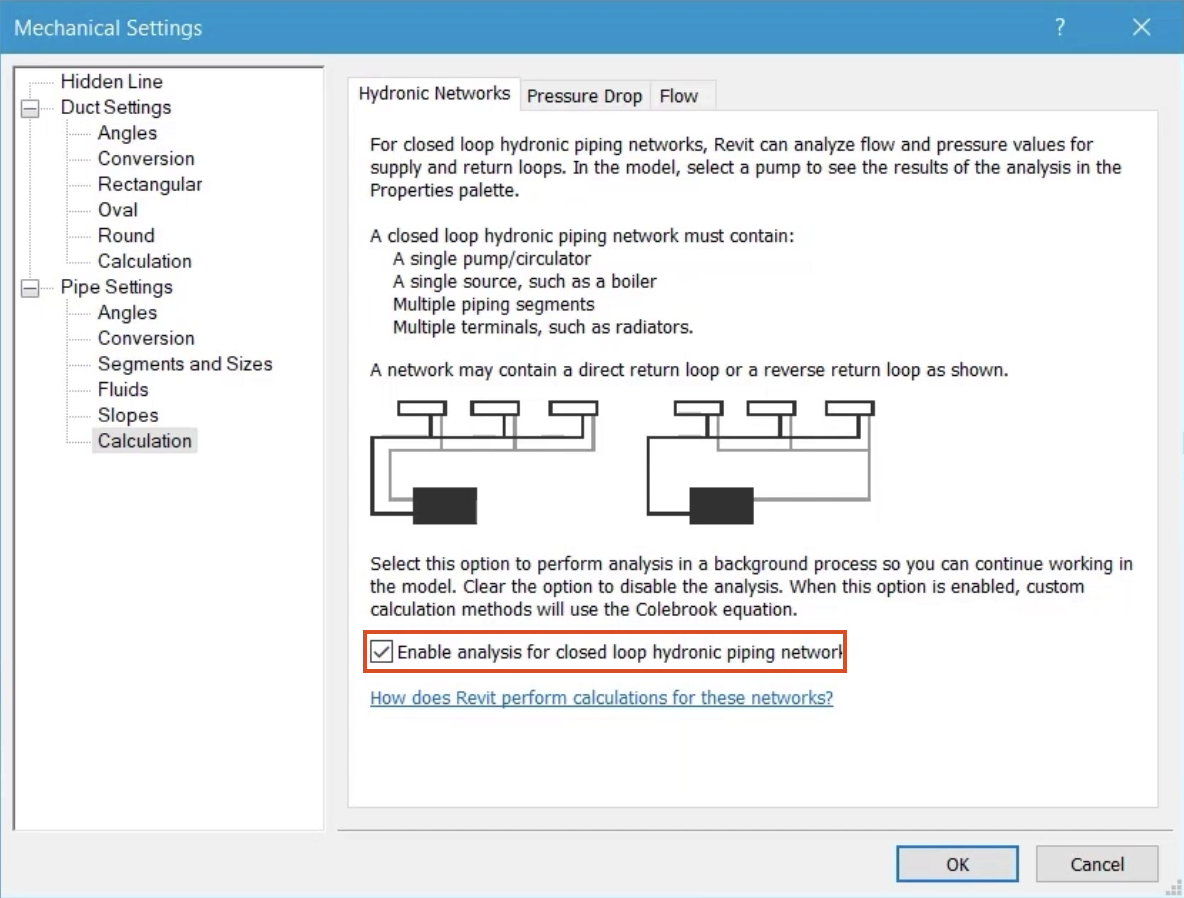

Understand closed loop hydronic systems and create hydraulic separation.

Tutorial resources

These downloadable resources will be used to complete this tutorial:

Understand closed loop hydronic systems and create hydraulic separation.

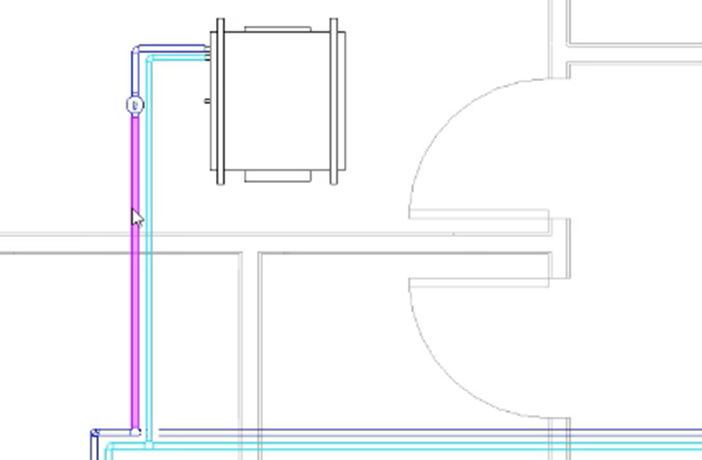

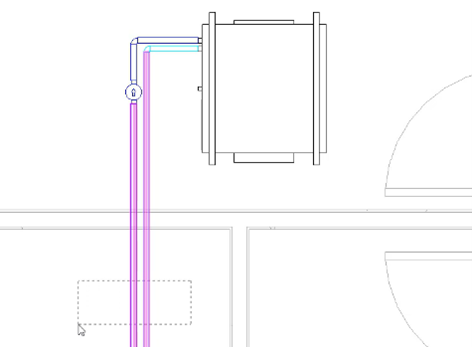

To achieve hydraulic separation of this loop:

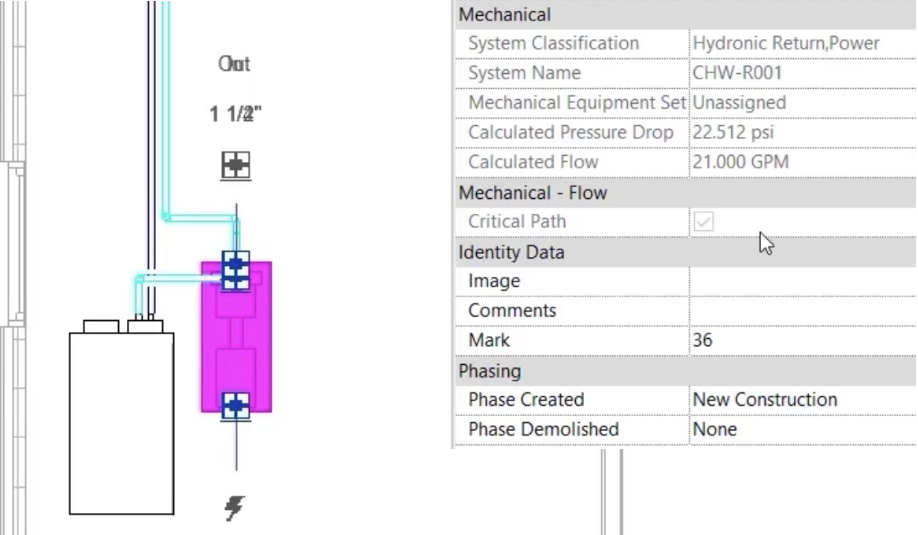

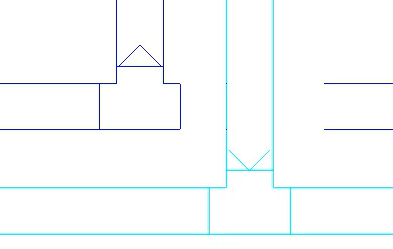

Arrow symbols indicating flow and return appear at the point of separation of the loop if separation is successful.

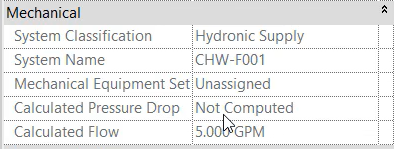

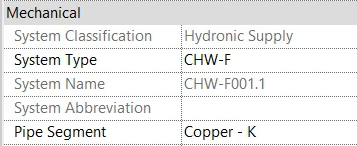

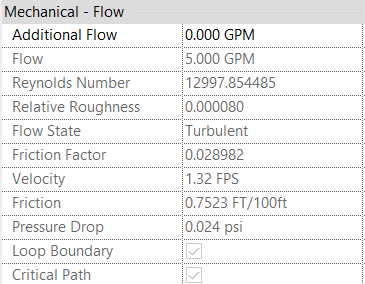

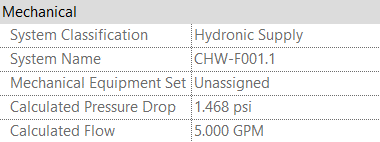

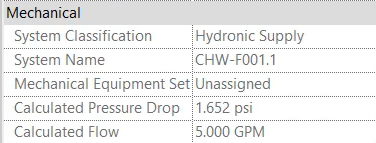

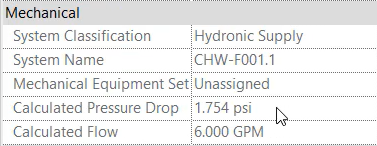

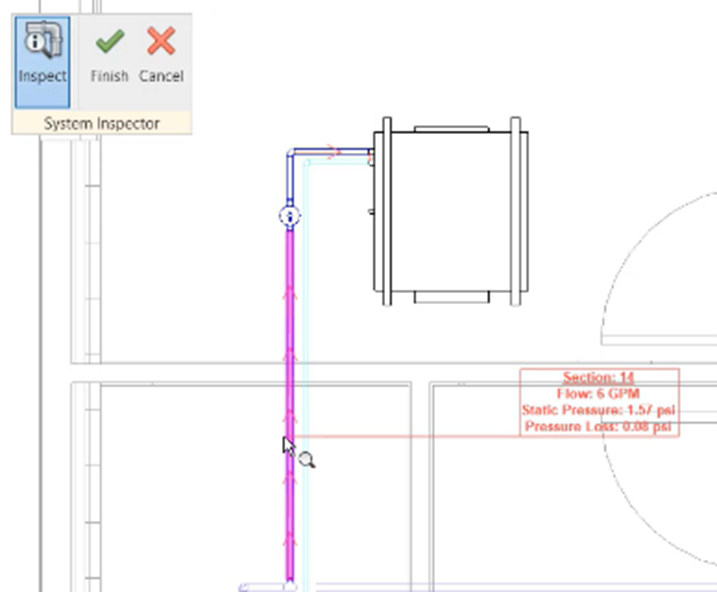

This section of pipe is now part of the separated loops boundary, and where it had previously been a loop off of the original critical path, it is now a separate critical path with all of the associated information.

Any changes made to this loop that would alter flow rates or pressure drop will now be seen at the inline pump.

If separation of a loop is no longer required: