& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

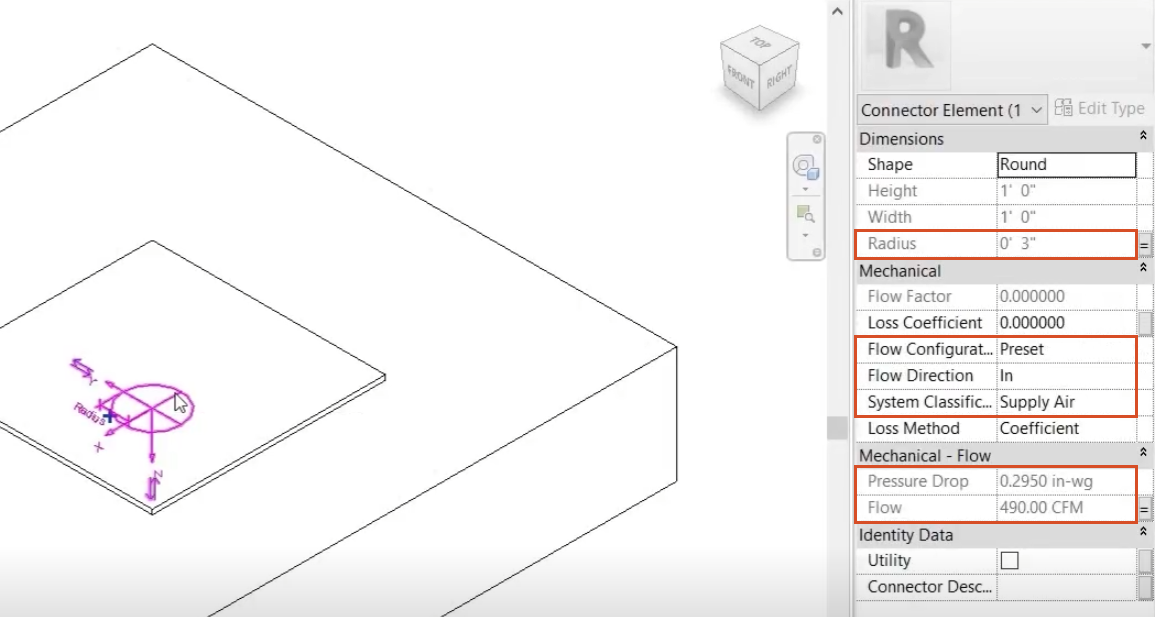

Understand values within a mechanical system and review connector configurations within the family editor.

Tutorial resources

These downloadable resources will be used to complete this tutorial:

Understand values within a mechanical system and review connector configurations within the Family Editor.

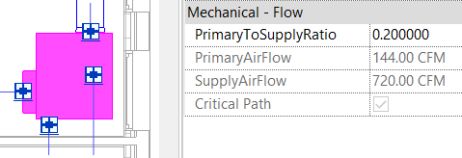

This equates to a total flow rate of 720 CFM.

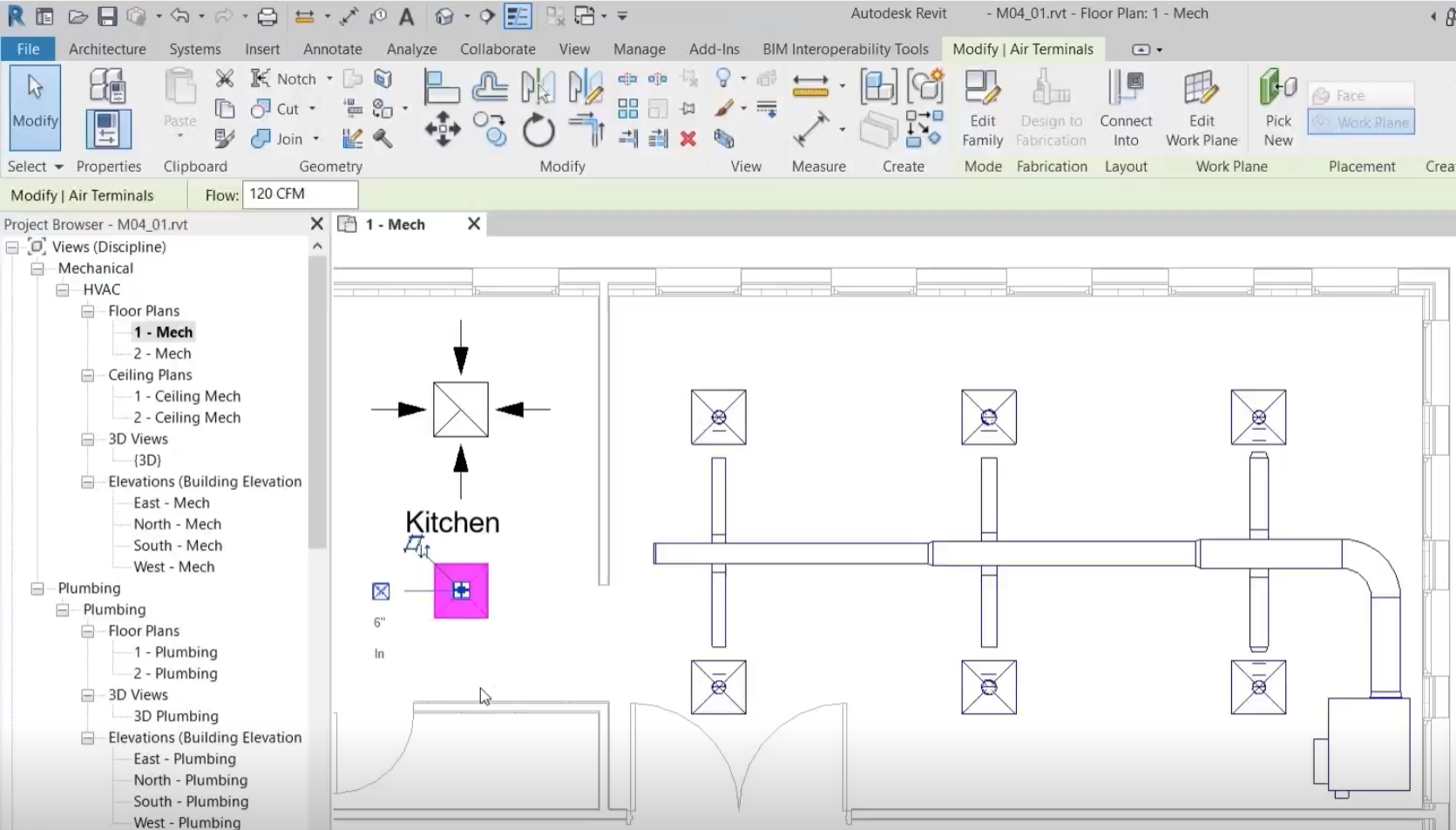

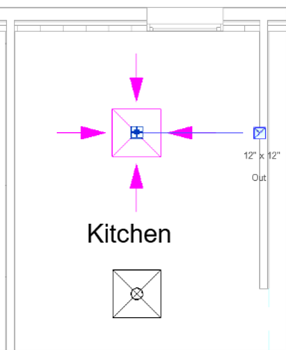

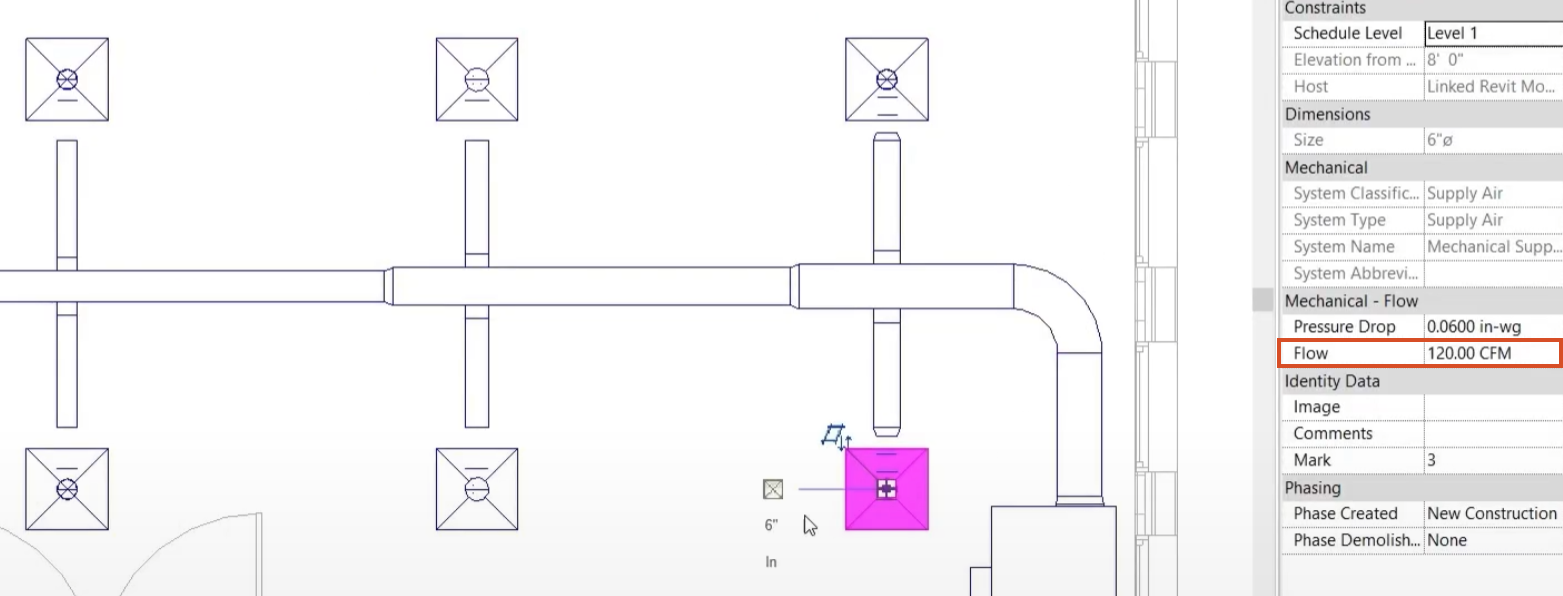

To review the connector configuration of the air terminals in this system:

In the Properties palette, note the following: