& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

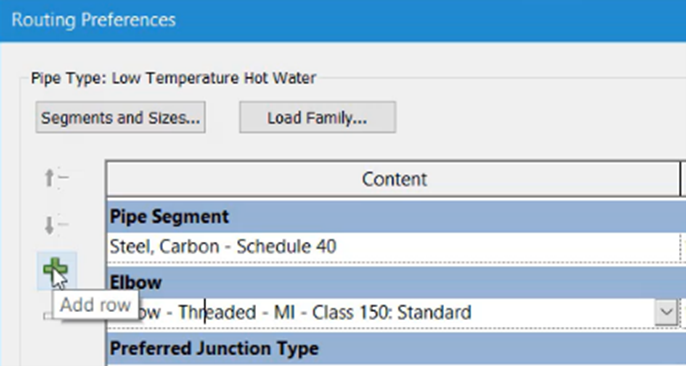

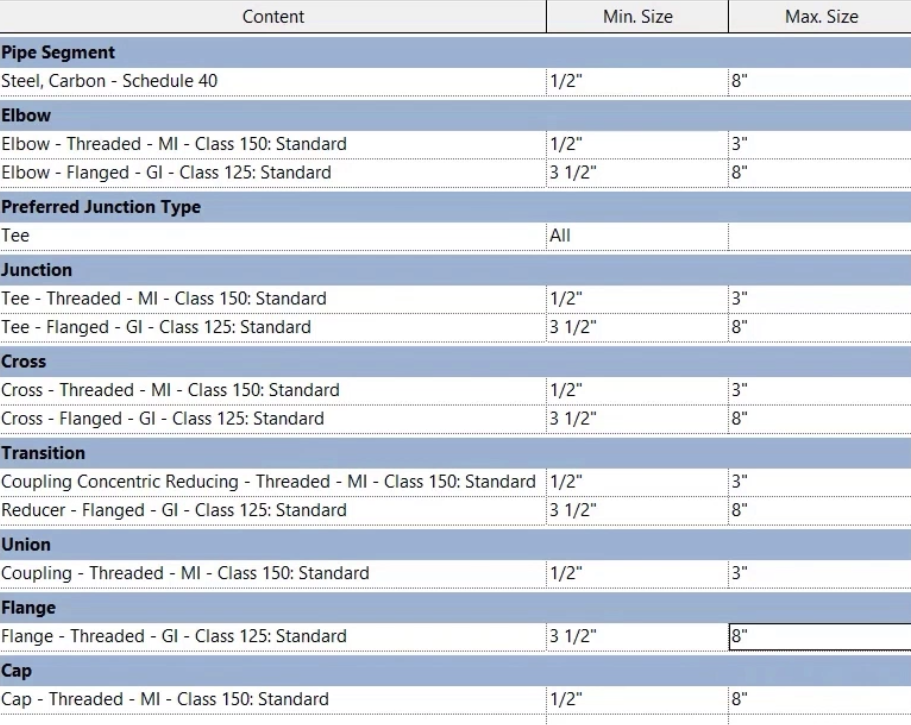

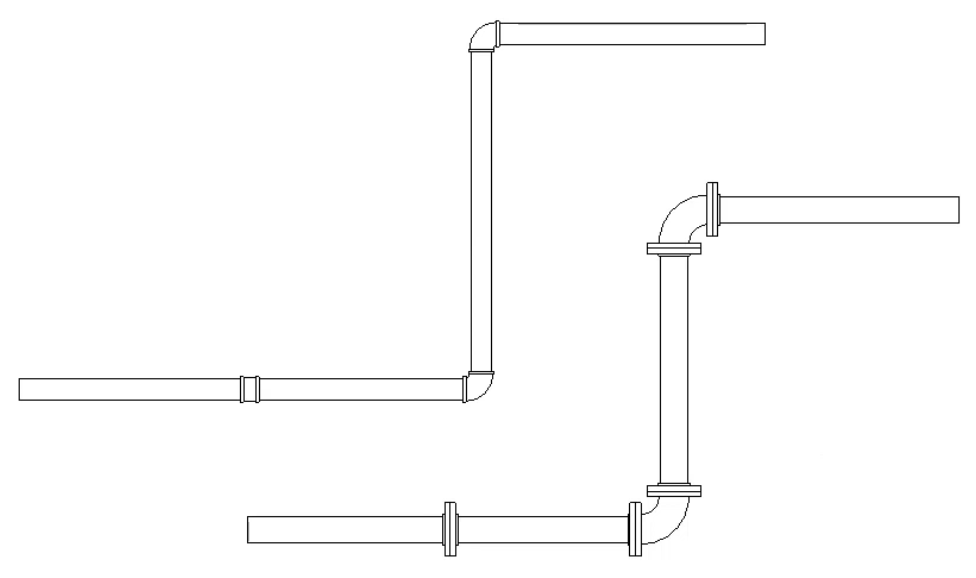

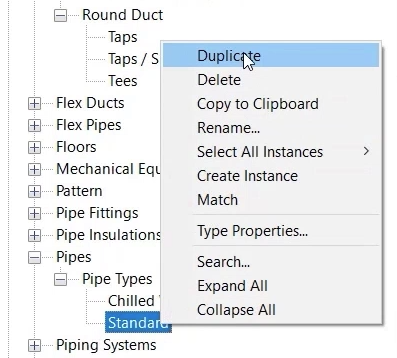

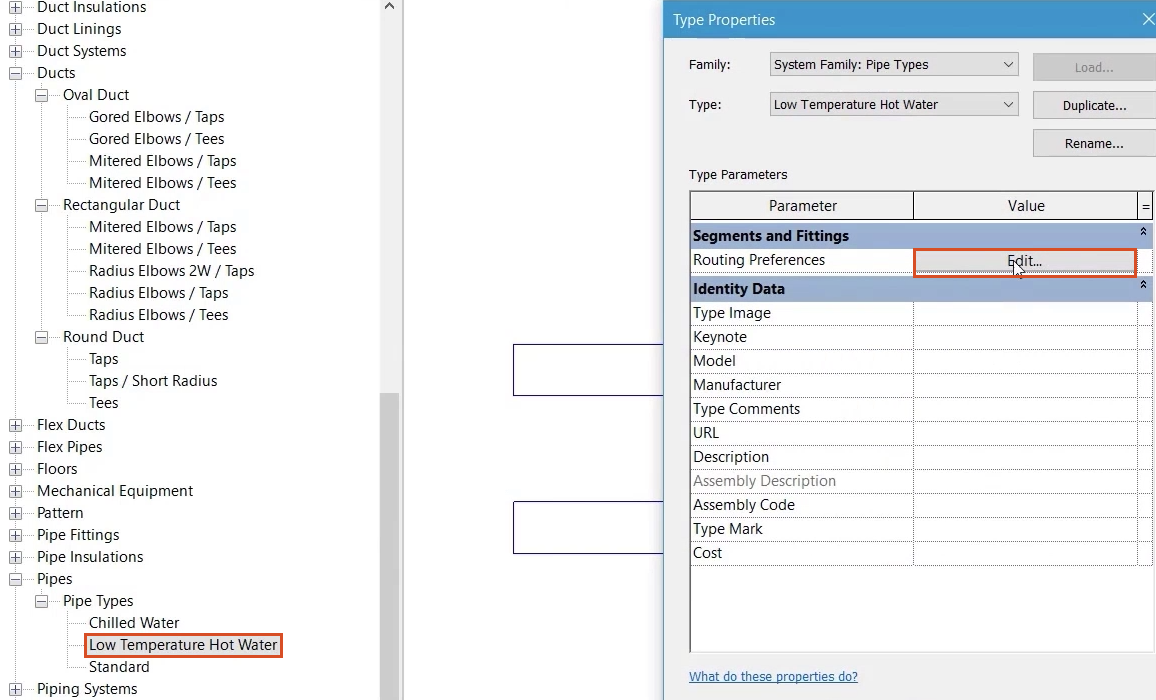

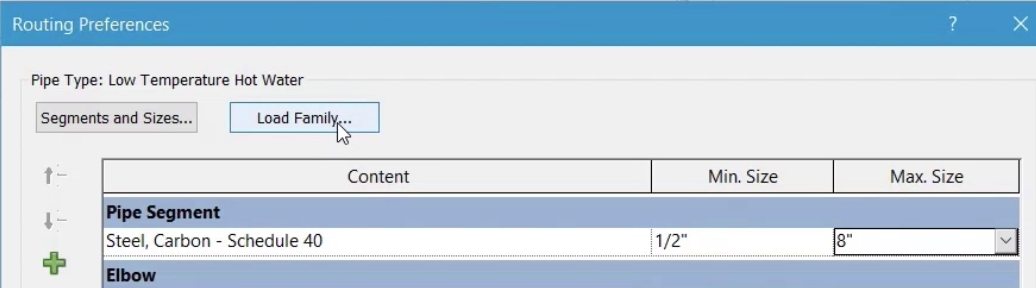

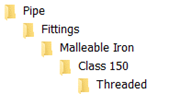

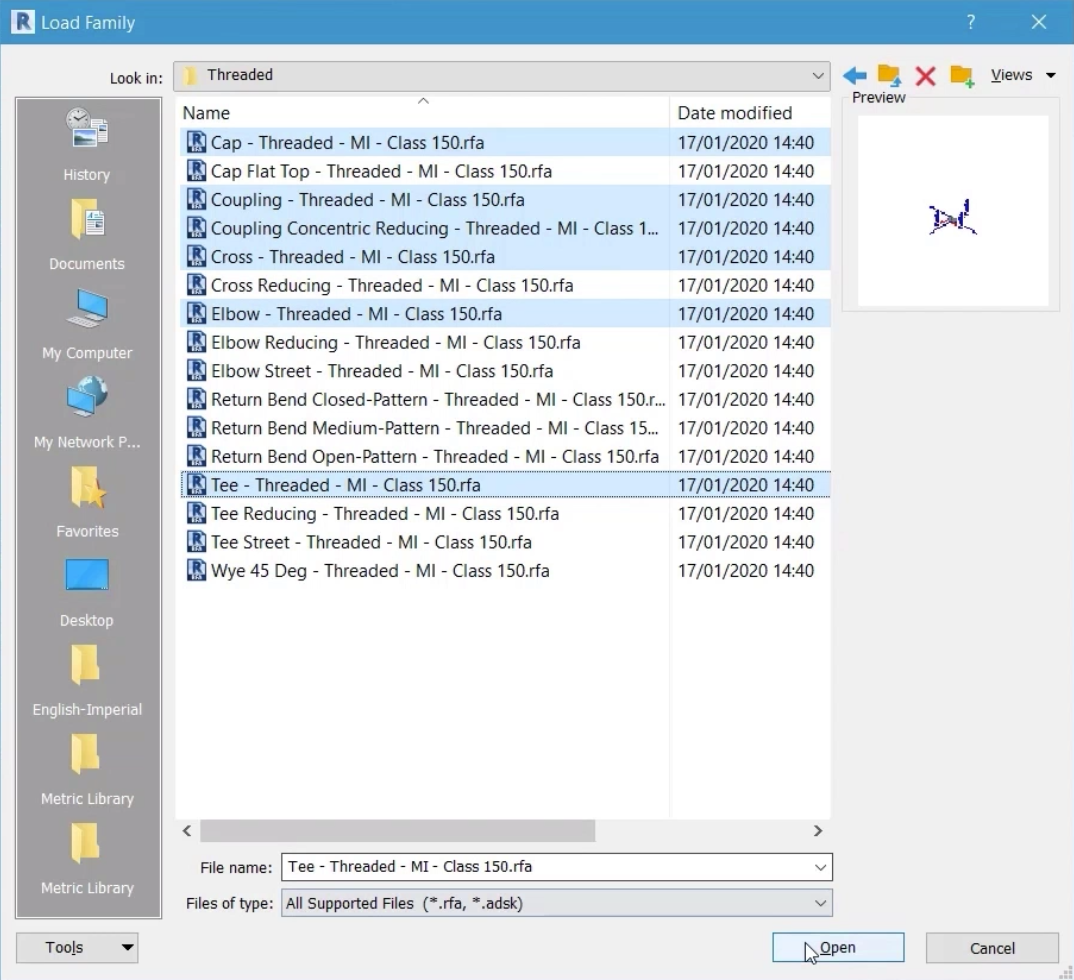

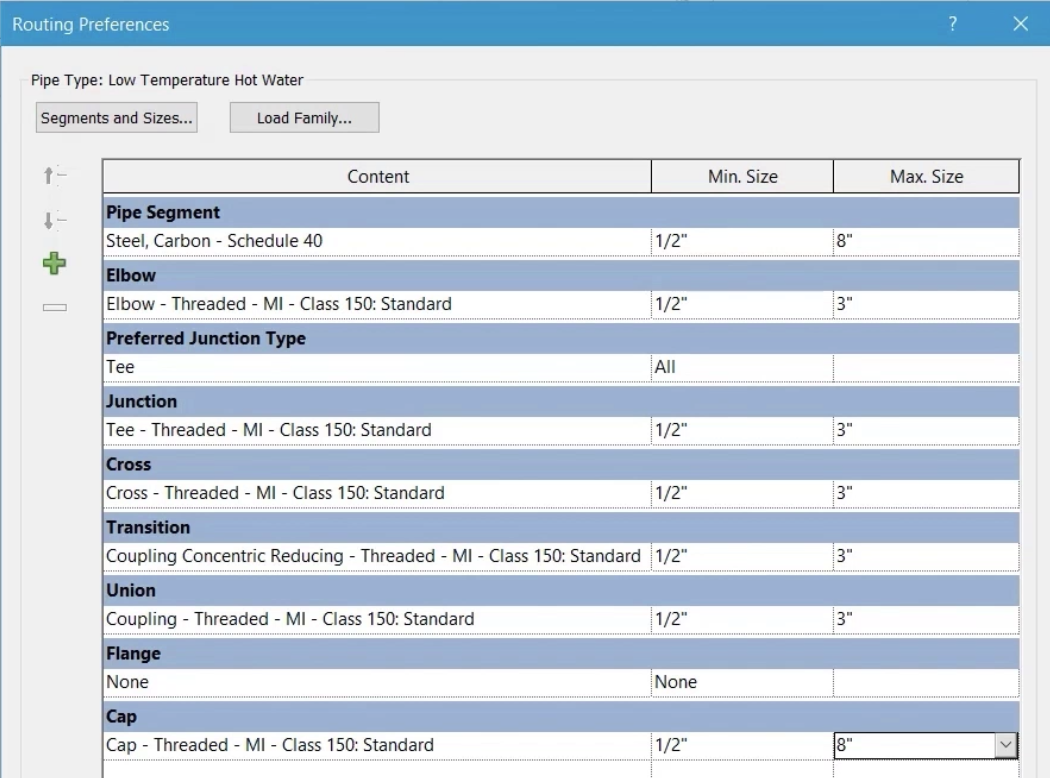

Set properties and routing preferences, then test the new duct and pipe types.

Set properties and routing preferences, then test the new duct and pipe types.

To create a new duct type:

For pipes sizes larger than 3", a flanged connection will be used.