Success Story

Making BIM as great power of construction phase

Customer challenge

BTUK ME is an EPC contractor of the basalt fiber rebar manufacturing plant. The construction phase was critical, and leveraging the BIM models from the design stage on-site ensured their total value and consistency.

Coordination of disciplines

Numerous changes in one discipline of the BIM model should be coordinated with others to prevent outdated information in drawings and potential clashes inside a single discipline or between several disciplines.

Masterplan drawings are not actual

The site’s landscaping and utilities were carried out without an up‑to‑date master plan, the as‑built documentation for these works was provided late, and the design decisions were behind the construction works. This problem led to challenges in coordinating utilities and landscaping, resulting in delayed decision‑making on the construction site. It necessitated significant time to conduct site inspections and become acquainted with the existing conditions and construction updates.

Tracking work dynamics and project progress

A significant challenge is obtaining real-time and accurate data from the construction site for daily progress reporting. Data collection by classic report methods may lead to delays and potential inaccuracies and not always depict the visual nuances of construction progress. Maintaining consistency and standardization in daily logs across various teams and subcontractors can be difficult.

Difference between as‑built and shop drawings. Not enough data for Digital Twin

One of the customer’s requirements was the development of a Digital Twin of the plant, for which it was necessary to combine shop drawings, as‑built documentation, and real‑time sensor data. The survey of MEP systems inside the building was not carried out; as‑built documentation was developed without considering in‑place changes and insufficient data regarding rising pipes and duct elbows. As a result, the actual situation in the facilities differed from that in the drawings.

Project goals

Optimize Discipline Coordination: Implement real-time BIM updates and on-site consulting to improve collaboration across all project disciplines. Aim to reduce project clashes by 65% and increase coordination efficiency by 30% within 3 months of starting the construction phase. Ensure this approach is confirmed and agreed upon with project managers and discipline leads.

Ensure Accurate Masterplans: Utilize aerial drone surveys and panoramic images to maintain current masterplan drawings and as-built documentation. Update masterplan drawings bi-weekly and reduce site inspection time by 40%. Achieve the first set of updates within 2 weeks and maintain bi-weekly updates throughout the construction phase, as confirmed with site management and design leads.

Enhance Progress Tracking: Implement 360-degree photography to provide comprehensive visual documentation of construction progress. Achieve daily visual documentation of the site and resolve 90% of discrepancies identified within one week. Start weekly documentation within 1 month and review progress monthly, with approval from project stakeholders and team leaders.

Develop an Accurate Digital Twin: Create a Digital Twin by integrating laser scanning data and real-time sensor information with existing documentation. Aim for 95% accuracy in as-built documentation compared to actual site conditions. Complete the initial Digital Twin development within 4 months and update it with new data every 2 months after that, as agreed upon with the engineering and BIM teams.

Solution

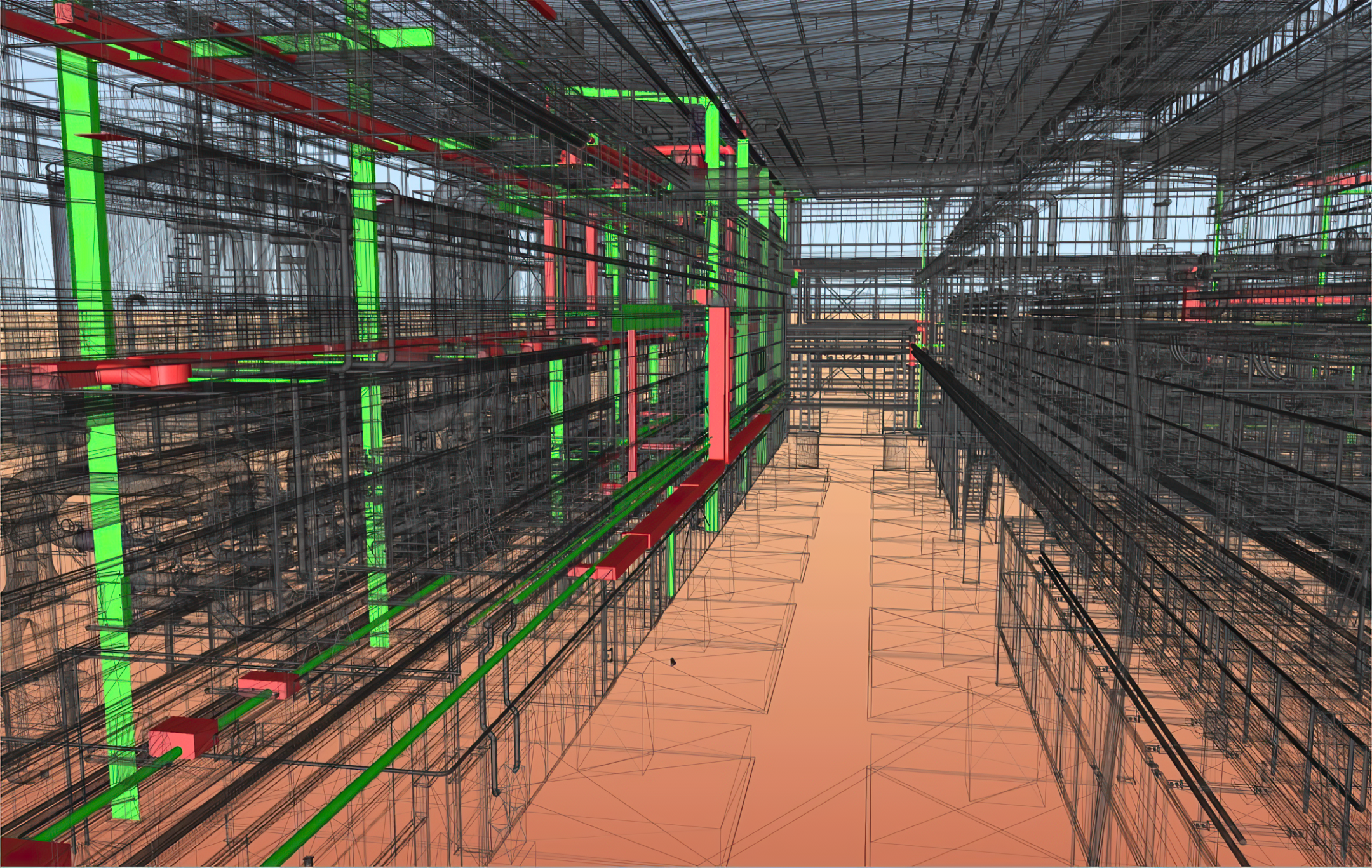

On-Site BIM Consulting

SIGNAX team addressed coordination challenges by providing on-site BIM consulting and training from day one. The training covered Autodesk and SIGNAX software, including Autodesk Revit, Navisworks, ACC DOCS, and SIGNAX TOOLS. The construction BIM model was continuously developed and updated, speeding up project development and reducing clashes. Deploying an Autodesk Revit server facilitated real-time BIM model synchronization, enabling multiple team members to work on different disciplines simultaneously, enhancing productivity and minimizing conflicts.

Aerial Drone Surveys and Panoramic Capturing

The Digital Survey Department conducted regular drone flights to produce orthomosaics, Digital Elevation Models (DEMs), and point clouds. These updates provided current site conditions, improved understanding, and reduced site inspection time by 40%. Aerial imagery enhanced visualization of construction progress for both on-site and remote teams. Orthomosaics corrected landscaping inaccuracies before completion, while DEMs and point clouds facilitated accurate material planning and network management.

360-Degree Imagery

360-degree imagery offered a complete visual record of the construction site, aiding in progress tracking and virtual inspections. This approach improved communication and collaboration by allowing stakeholders to visit the site virtually and discuss issues in real-time. Detailed visual data and BIM model comparisons helped identify problems early, optimize workflows, and make informed decisions to keep the project on track.

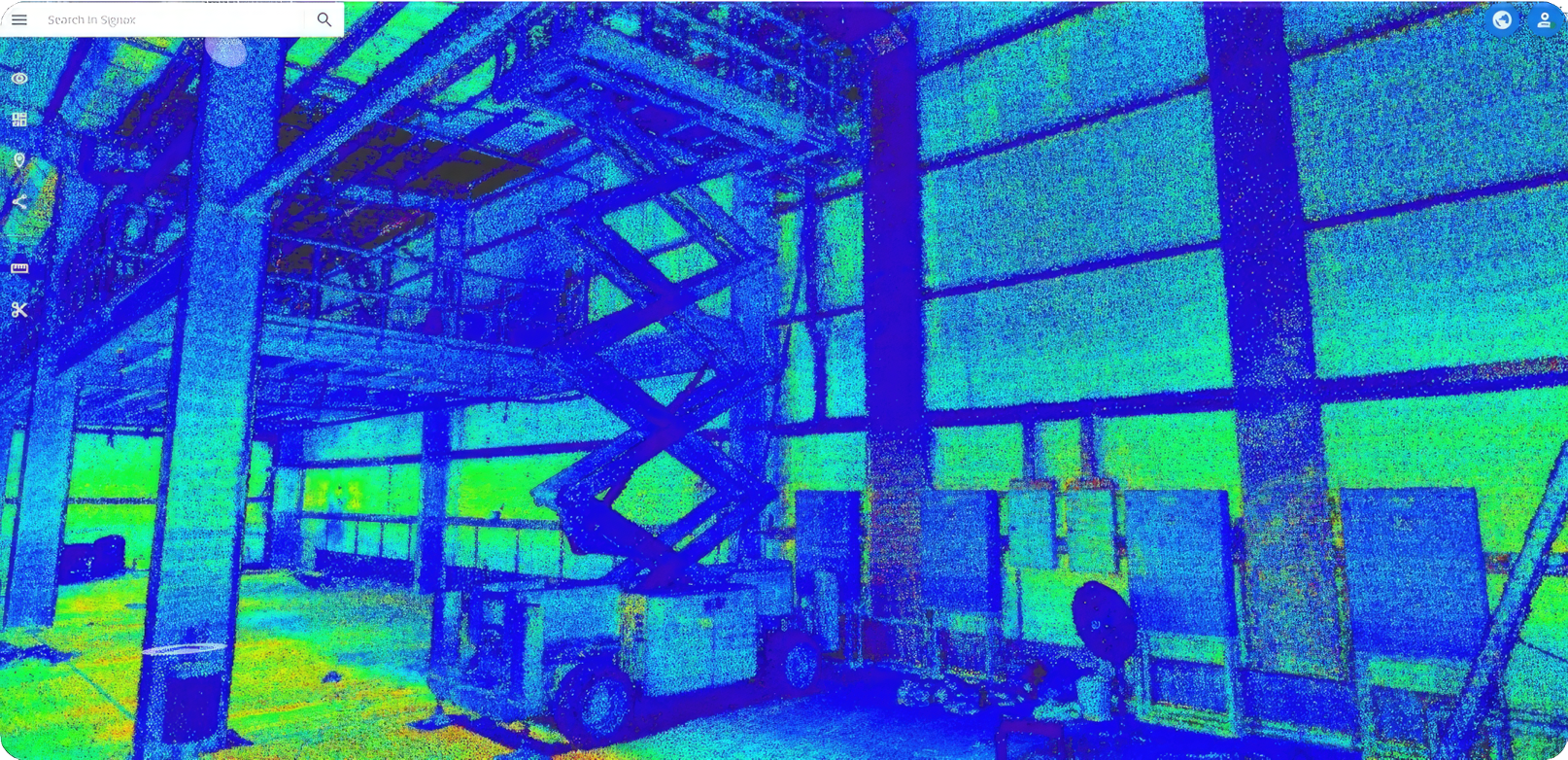

Laser Scanning and Point Clouds

SIGNAX surveyors performed two laser scanning iterations: during MEP system installation and after architectural finishing. Point clouds enabled accurate modeling of MEP systems and identified actual system positions. Data was accessible through the SIGNAX point cloud web viewer. This improved the quality of as-built documentation and allowed precise scope-of-work calculations.

Business outcome

Overall, these solutions led to better project coordination, more accurate data, optimized progress tracking, and enhanced communication. This comprehensive approach not only streamlined workflows but also ensured that the project was completed on time and met the highest standards of quality and efficiency.

Conclusion

In conclusion, integrating advanced BIM consulting, real-time data synchronization, and cutting-edge visual documentation techniques significantly enhanced the project's execution. By improving coordination, ensuring accurate and timely site information, optimizing progress tracking, and facilitating clear communication, these solutions effectively addressed the key challenges and met the customer's business needs. The successful application of these technologies not only streamlined project workflows but also ensured timely and efficient project delivery, showcasing the value of leveraging innovative approaches in construction.

Project summary

- 360

- 2024-06-03

Duration & delivery

- Architecture, Engineering & Construction Collection

- AutoCAD

- Autodesk Platform Services

- BIM 360

- Civil 3D

- Docs

- Dynamo Studio

- Navisworks

- ReCap Pro

- Revit

- AutoCAD

- Autodesk Platform Services

- Autodesk Platform Services

Autodesk solutions

- BIM

- BIM/CAD Standards

- Forge

- Migration, Data Loading & Interoperability

- Assessment of Needs

- Implementation

- Pipeline Development

- Process Automation

- Strategy & Planning

- Workflow Optimization

- 3D Modeling

- Design/Sales Automation

- Plotting

- Prototyping

- 3D Scanning

- Photogrammetry

- Software Development & Customization

- Installation

- Configuration & Deployment

- System & Software Maintenance

- System Integration

- Updates & Upgrades

- Training

- Rendering

Services provided

- Architecture

- Civil Engineering

- Construction Design

- Facility Management

- MEP Engineering

- Mining & Quarrying

- Oil & Gas

- Other Engineering Industries

- Structural Engineering

- Utilities & Telecommunications

- Water & Wastewater

Customer industry

Digital Construction as a Top Value to Reach Project Quality

MR Group has been successfully operating in the property development market since 2003. The company is a leader in residential and commercial development. Its portfolio includes 50 projects with total area more than 7M m². The company has received plenty of honorable professional awards.Since 2016, MR Group has been actively using BIM technology at all project lifecycle stages. After implementation of Employer’s Information Requirements (EIR) for design contractors, MR Group brings all advantages of digital technologies directly to the construction sites.

Need help? Contact us.

Contact Partner Finder for help using the online search tool and more. The Autodesk Assistant can help with Autodesk products, answer questions, or send you to an agent.

Partner Finder Terms of Use

By accessing and using Partner Finder, you acknowledge and agree to the following Additional Terms as referenced in the Website Terms of Use: (i) Partner Finder may be modified, updated, interrupted, limited, suspended, or discontinued at any time without notice or liability; (ii) any query or request for information regarding a specific provider or provider services may be forwarded to that provider, however Autodesk in its discretion may retain a record to conduct business analytics to improve Partner Finder and other Autodesk products and services; (iii) Autodesk has no obligation to enforce any terms on your behalf against another user; and (iv) any feedback you provide in connection with a provider, including ratings or reviews, is a non-confidential “Submission” as defined in the Website Terms of Use. You are advised to conduct your own independent analysis and assessment of any information provided by or though Partner Finder, including whether a selected provider is appropriate for your particular circumstances. Without limiting the Website Terms of Use, Autodesk does not warrant, endorse, guarantee, or assume responsibility for any service advertised or offered by a provider through Partner Finder or any hyperlinked website or service. Autodesk is not liable for the content of this site, or for the consequences of any actions you may take based on information provided by, or through, this site. You release Autodesk and its affiliates and subsidiaries from all liability arising from your use of Partner Finder, including any hyperlinked website, service, or content.

Translation tool disclaimer

This page has been translated for your convenience using a machine translation service. Reasonable efforts have been made to provide an accurate translation; however, no automated translation is perfect nor is it intended to replace human translators. As a result, this translation may contain errors and inaccuracies. Autodesk provides no warranties, either express or implied, about the accuracy, reliability, or completeness of the machine translation and disclaims all liability for any losses or damages caused by, or resulting from your reliance on, this translation. The English version of this website is the official version.