& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Toy design and manufacturing is a combination of creativity and technical skill, converting imaginative concepts into tangible toys. This process flows from ideation and prototyping, through detailed design and manufacturing, to quality control, resulting in packaging that enhances market appeal. Each toy, whether a bespoke item, collector's treasure or action figure, meets the highest standards and caters to a vast array of tastes, bringing delight to children and adults alike.

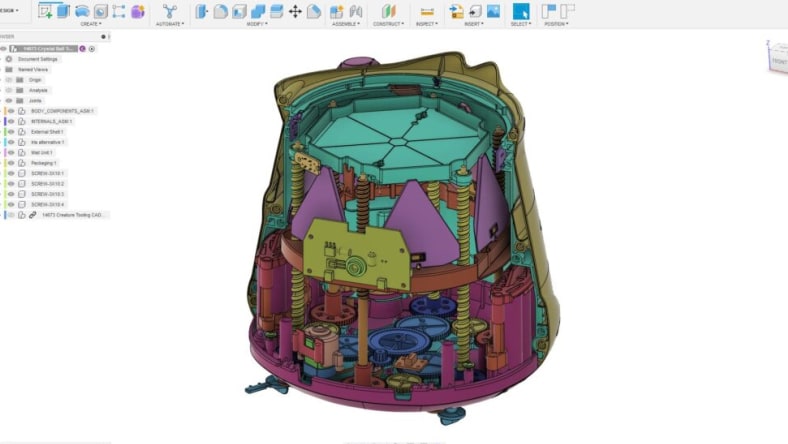

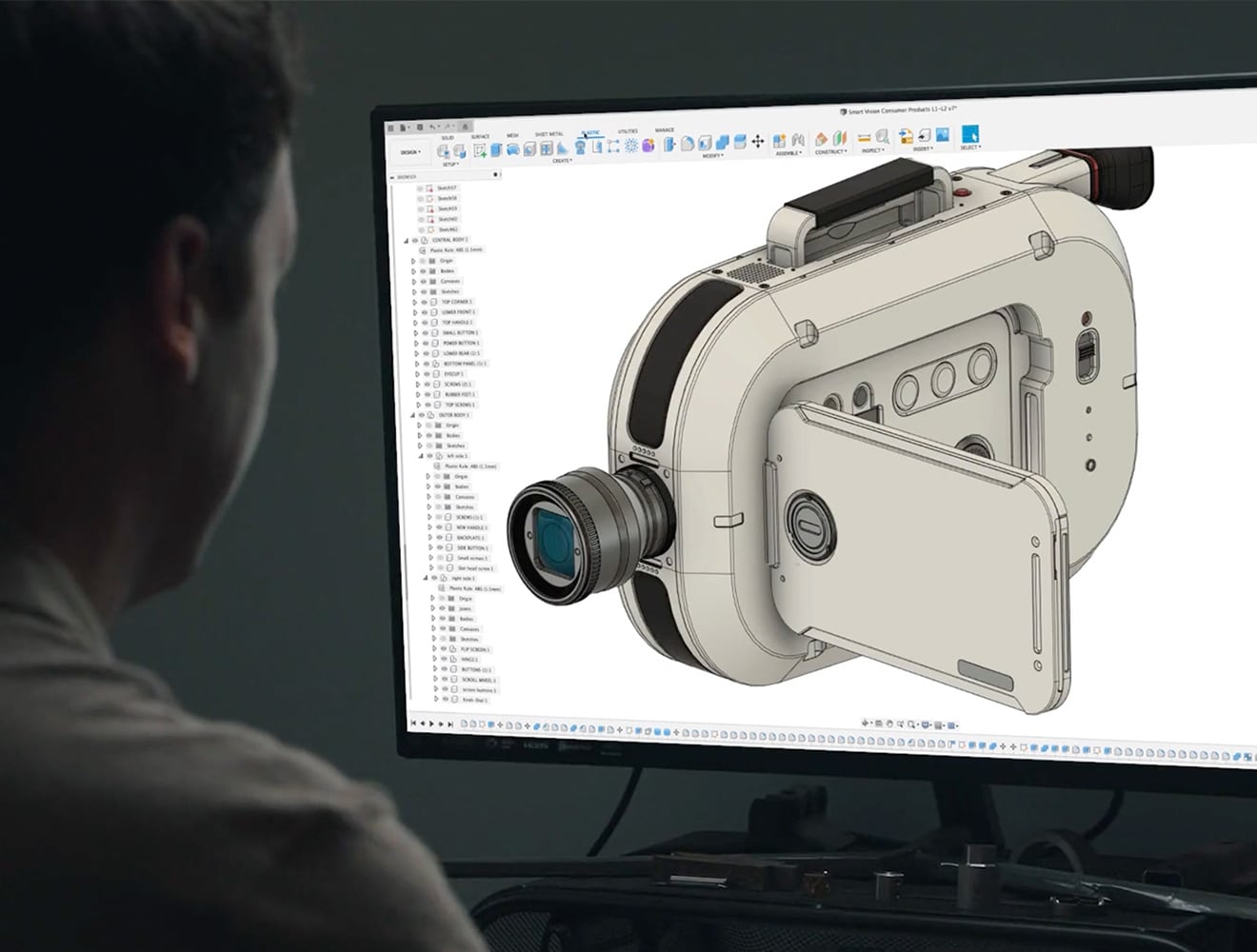

Toy design software, such as Autodesk Fusion, is a key tool for creating and visualising toy concepts before production. Fusion, a cloud-based 3D CAD, CAM and CAE tool, combines industrial and mechanical design, simulation and collaboration, allowing for rapid design iteration. Its comprehensive toolset and intuitive interface let designers bring toy designs to life and make sure they're manufacturing-ready, making it a top choice for its user-friendliness, flexibility and powerful capabilities

Toy design software (US Site) like Fusion streamlines the design process, reducing the time from concept to manufacturing-ready design.

The software enables highly accurate designs, making sure the final product flawlessly mirrors the initial concept.

Digital prototypes allow designers to rectify issues pre-production, significantly reducing costs associated with physical prototyping.

With cloud-based capabilities (US Site), Fusion fosters seamless remote collaboration, uniting designers from various locations.

In the context of Autodesk Fusion, the following factors are significant when manufacturing toys:

Cloud-based product design software for manufacturing, 3D modeling, electronics, simulation, and data management

Fusion provides comprehensive tools for designing in 3D, making it easier to create intricate, detailed and realistic toy models.

With integrated CAM, Fusion simplifies the process of preparing 3D models for manufacturing, ensuring error-free and efficient production.

This feature provides photorealistic images of the toy design, allowing designers to visualise the final product in different materials, environments and lighting conditions.

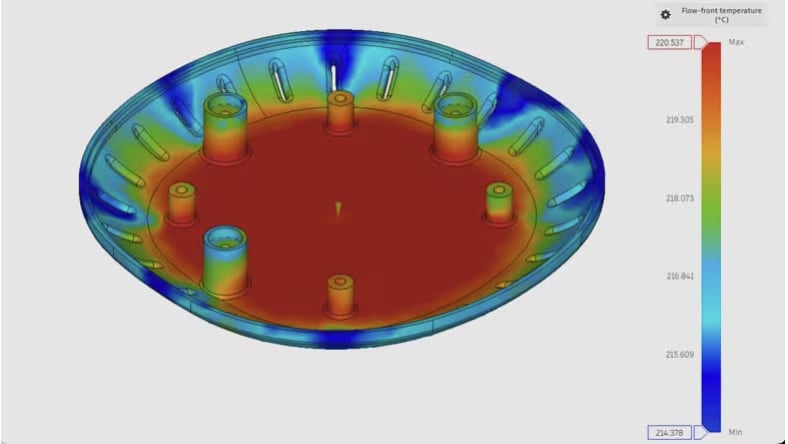

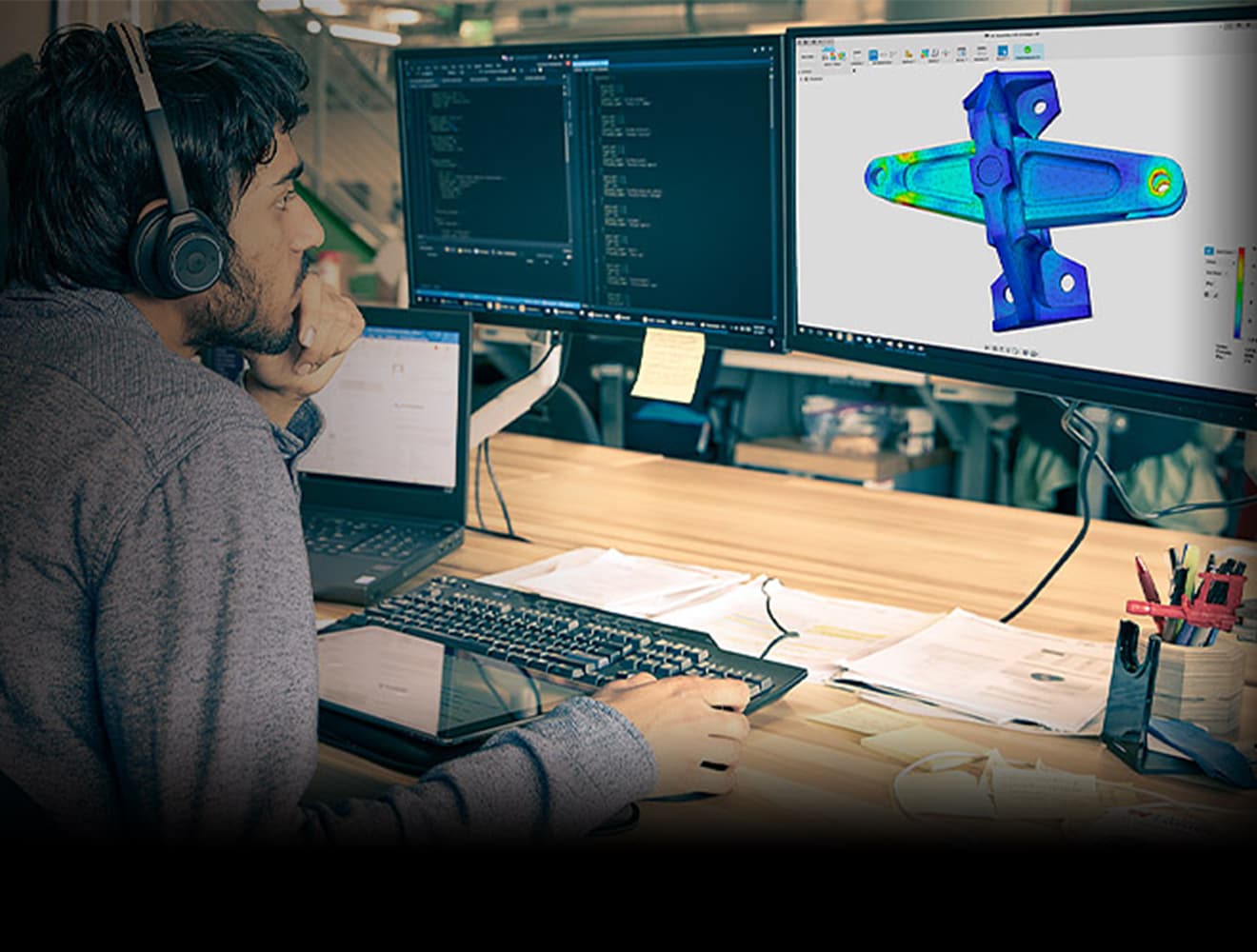

Fusion can simulate real-world conditions, including stress and motion on a toy design, ensuring its durability and functionality before production.

This capability allows for the design and interaction of multiple components in a single toy design, simulating real-world assembly and operation.

This feature automates design options based on specific input parameters, optimising toy designs for performance, material usage and manufacturing methods.

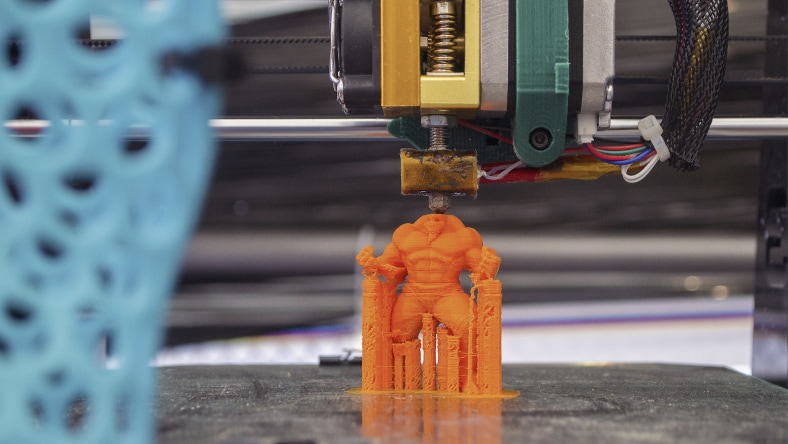

Fusion supports 3D printing and other additive manufacturing processes, enabling rapid prototyping and production of toy designs.

Fusion's sculpting tools allow designers to manipulate and shape models as if they're made of clay, ideal for organic shapes in toys.

The Autodesk Fusion Design Extension is a suite of advanced 3D design and modelling tools that can significantly enhance the process of toy design. Here's how:

The Fusion Manufacturing Extension is a comprehensive suite of tools that significantly optimises the toy manufacturing process in various ways:

The Fusion Simulation Extension is a robust suite of tools that significantly enhances the toy testing and validation process in various ways:

– Carl Budd, Engineering Manager, Moose Toys

Discover how leveraging Fusion and its add-ons can significantly boost the effectiveness and impact of your sustainability initiatives in toy design and manufacturing.

The Manufacturing Extension in Fusion provides advanced manufacturing tools that assist in producing intricate, high-quality toy parts more efficiently. By optimising machining strategies, it reduces waste, energy usage and production time, thus contributing to sustainability in toy design.

Fusion's sustainability insights feature provides detailed data on the environmental impact of various manufacturing processes. It aids toy designers in making informed decisions about materials and methods, with the aim of reducing the carbon footprint of their toy designs.

Makersite for Fusion is a robust add-on that provides comprehensive data on materials, costs and sustainability. It supports informed decision-making in toy design, recommending greener, less carbon-intensive materials and processes.

Explore the rise of eco-friendly toys, the role of Fusion in sustainable toy design and manufacturing, and the educational impact of such toys.

See how Moose Toys uses Fusion to prototype, design and make the highly successful Magic Mixies toy line.

Learn more about toy design and manufacturing with these top questions frequently asked by users.

The toy design process typically involves several steps: researching current trends and consumer preferences, brainstorming and sketching toy design ideas, creating 3D models of the designs, prototyping, testing for safety and durability, and finally, manufacturing. Designers frequently use software like Autodesk Fusion to assist with the 3D modelling, prototyping and testing stages.

Before new toy designs go into production, they undergo a meticulous testing process. First, a prototype of the toy is created, designed to be as close as possible to the final product without requiring a substantial financial investment. After the prototype is ready, play-testing sessions are conducted with the target audience to evaluate the toy's appeal, functionality and safety. Following this, the toy is subjected to durability and safety tests, including drop, tension and torque tests, to ensure it can endure regular play and meets safety standards for its intended age group. Feedback from these testing phases is then used to make any necessary revisions to the design before it is finalised for production.

Modern technologies like 3D printing have significantly impacted the toy manufacturing process. Traditionally, toy manufacturing involved creating moulds and mass-producing toys, which could be time-consuming, expensive and limited in design possibilities. With 3D printing, manufacturers can easily produce unique and intricate designs without the need for moulds. This has made it much cheaper and more efficient to create toys, even at home.

Furthermore, 3D printing allows for rapid prototyping, meaning ideas can be brought to life quickly and changes can be made easily. Toys can be tested and refined faster, resulting in a more efficient design process. 3D printing also offers the potential for greater sustainability in toy manufacturing. As a form of additive manufacturing, it minimises waste by using only the material needed for the toy. Moreover, it has the capacity to use bioplastics and recycled materials, positioning 3D printing at the forefront of eco-conscious manufacturing processes.

Autodesk provides a suite of software that is extensively utilised by toy designers.

These Autodesk tools can be used separately or together to create a comprehensive workflow for toy design and manufacturing.

Yes, Autodesk Fusion is available for free personal use for individuals who are doing home-based, non-commercial design projects. This version includes basic functionality. However, it is important to note that to qualify for free usage, users should generate less than $1,000 USD in annual revenue from their designs. You can register for a personal licence on the Autodesk website.

Autodesk Fusion facilitates customisation in toy design by providing a comprehensive platform that allows manufacturers to design, prototype and fabricate toys using an array of materials. This includes the ability to model unique and intricate designs, as demonstrated in various tutorials.

Fusion also enables the use of advanced design and manufacturing capabilities, including generative design and AI-powered enhancements, allowing for the creation of highly customised and unique toy designs. Furthermore, Fusion's mass customisation capabilities enable efficient iteration and adaptation of designs to suit specific requirements or preferences.

Autodesk Fusion's rendering tools can greatly assist in marketing and selling a toy design. These tools allow designers to create compelling, photorealistic renderings of their designs, which can be used to effectively communicate the design and concept to a wide audience. This visual storytelling can be a crucial part of the sales and marketing process. Furthermore, Fusion's in-canvas rendering allows for real-time previews of the render, which can be continuously updated for optimal results. Rendered images can be used in presentations, packaging design or for immersive viewing, enhancing the overall marketing strategy.

Autodesk Fusion helps toy designers and manufacturers stay competitive in a number of ways:

Advanced Capabilities: Fusion extends beyond traditional 2D and 3D toolpath generation, enabling the production of intricate components with precision through multi-axis machining.

AI Enhancements: Fusion incorporates artificial intelligence to enhance manufacturing. The AMAIZE add-in, for instance, uses AI to predict and resolve print issues, optimise print files and gain valuable design insights, significantly improving the manufacturing process.

Unified Workflows: From concept to manufacturing, Fusion streamlines workflows with integrated cloud-based CAD, CAM, CAE and PCB design tools. It unifies design and manufacturing capabilities, data and technology.

Innovation and Sustainability: Fusion is continuously evolving, incorporating AI, machine learning and generative design technologies to push the boundaries of product development.

Remote Access: Fusion allows real-time collaboration and provides access to designs anywhere, anytime, accelerating time to market.

Fusion by Autodesk supports sustainable toy design in several ways:

Materials: Fusion includes resources to help designers choose sustainable materials such as bioplastics or recycled materials.

Additive Manufacturing: Fusion supports 3D printing, which can significantly reduce waste and energy usage.

Generative Design: Fusion's generative design capabilities help reduce material usage, contributing to sustainability.

Efficiency: Fusion aids in optimising manufacturing processes, making them more energy-efficient and reducing waste.

Remember, proper assessment is needed when choosing materials to ensure the most sustainable options are selected.