Increasing Agility and Resilience in Manufacturing with New Processes

Traditional manufacturing lines have been far from agile—though carefully planned, hard to change. Efficient? Yes, but primarily because they specialize in making the same thing in the same way over and over.

Today, new fabrication processes and digital workflows are changing what’s possible, enabling manufacturers to adapt quickly and pivot easily to meet changing needs and dynamic conditions. And given the current global disruption, that’s more important than ever.

GreenBiz covers this trend in a recent article, showcasing how companies like Carbon, Fictiv, and HP are putting the flexibility provided by 3D printing and digitally enabled manufacturing to good use to make the products that healthcare workers need now—from face shields to nasal swabs—and how generative design tools from Autodesk are helping them get the job done.

Ready to build your skills in agile manufacturing? Check out these AU resources.

The Road to Agile Manufacturing with the Help of Fusion 360

Agile processes enable you to offer customers more choice and greater customization. Brett Cottle of Vertigo Technologies shares how he involves customers in the product design and development process and how his team has overcome key challenges to agility.

Leveraging Generative Design Technology to Enhance Product Design for Manufacturing

As the GreenBiz piece points out, generative design can be a valuable tool to enhance agility in the product design phase. In this class, Adam James and Mason Myers of Autodesk walk you through how to use generative design technologies built into Fusion 360.

From Concept to Reality in Under a Day with 2.5-Axis Generative Design and CAM

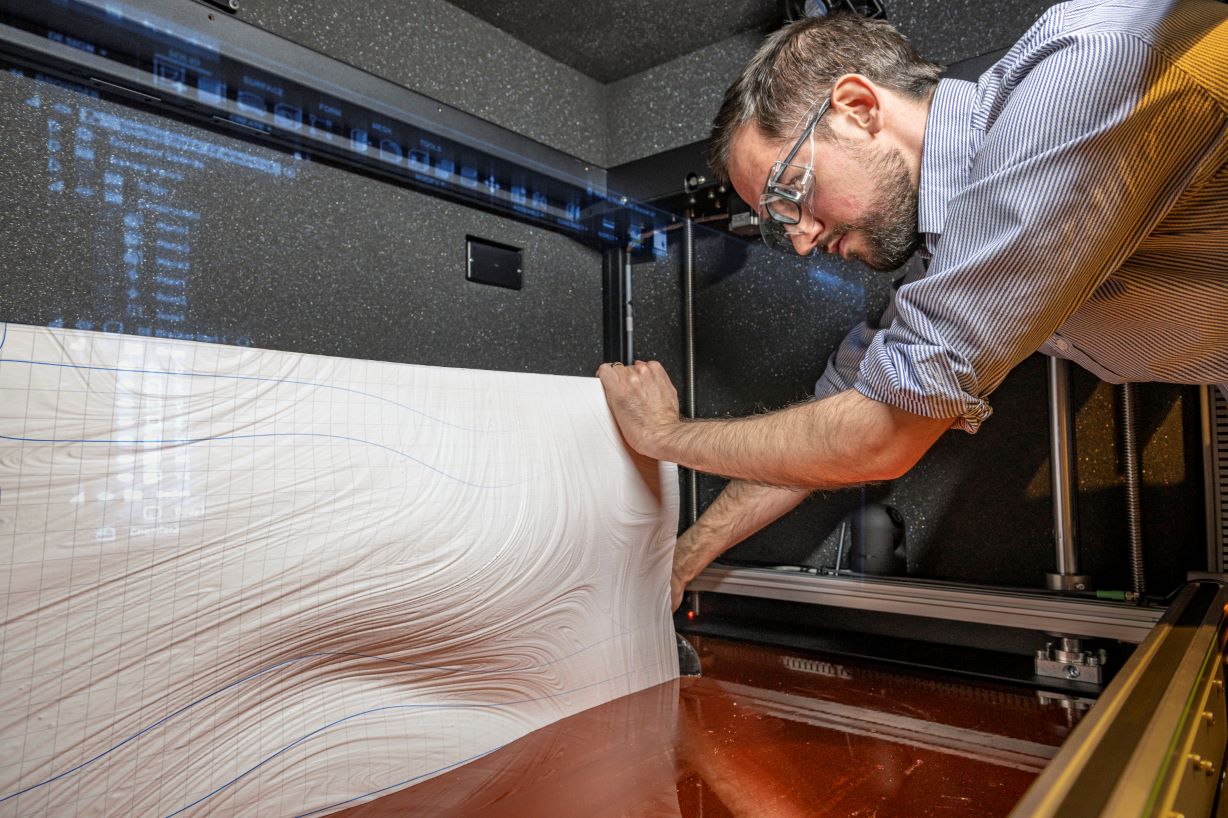

Being agile means you can change what you make and how you make it in a matter of minutes or hours, not days, weeks, or months. Ben Weiss and Christopher Wade walk you through the workflow to take a component from generative design through CAM and on to 2.5-axis CNC milling in under 24 hours.

Delivering an Automated Precision Manufacturing Facility for Off-Site Housing Products

Neil Lee shares how Berkeley Group, a leader in residential construction in the UK, is delivering an automated manufacturing facility for off-site housing products, maintaining agility while making building more efficient and sustainable.

Automation and the Future of Work

The Bosch Group converted a factory originally built in the 1960s to manufacture one product (televisions) into an agile facility that can fabricate a variety of components for niche markets as needed. They call it “manufacturing-as-a-service.” Pierre Maillot shares the work.

And you’ll find many more resources to help you create agile manufacturing processes at Autodesk University whenever you’re ready to learn.