AU Learning for Advanced Manufacturing

Advanced manufacturing is one of those terms whose meaning is constantly changing. And with the pace of innovation accelerating, its meaning is changing faster than ever.

Today, advanced manufacturing refers to new fabrication techniques like additive manufacturing and new subtractive processes like 5-axis machining. It refers to digitally enabled processes like simulation and generative design that can help you assess, iterate, and optimize designs before you make them. And it refers to what’s possible when you combine these technologies to create products that are lighter, smarter, more customizable, and more sustainable.

In short, advanced manufacturing refers to the techniques and approaches that help manufacturers to be more competitive today. Check out these learning resources and prepare yourself and your business for what’s ahead.

Subtractive manufacturing

Subtractive manufacturing involves subtracting material with a tool until you have your finished object. Today, it often means programming a CNC machine to fashion your material quickly and with a degree of precision that was previously impossible. CNC machines have been around since the mid-20th century, but new 5-axis machines have unlocked more options and designs that the old machines were incapable of.

- Dimples? Punches? Embosses? Learn how to create repeatable sheet metal features in Inventor with Pete Strycharske.

- Knowing when to choose between additive and subtractive manufacturing techniques can make a huge difference in your design approach, cost considerations, and outcomes. Greg Paulsen shows you how to get the best from both processes.

Additive manufacturing

While subtractive manufacturing has a major role to play in the creation of products, it does have limitations on what shapes it can produce. Additive manufacturing, often referred to as 3D printing, has very few limits. Additive systems lay down successive layers of material according to digital instructions until your object is complete, so whatever you (or an algorithm) can dream up, the 3D printer can probably make. It can be used for everything from rapid prototyping in plastic polymers to selective laser sintering (SLS) for the metal shell of a rocket engine.

- Need a drone? Learn the workflow to design, verify, and additively manufacture one quickly and easily using Fusion 360.

- Innovative manufacturers have recently discovered that by 3D printing the cooling circuits of an injection mold, they can significantly boost performance—improving the layouts, cycle times, and part quality. Discover how additive manufacturing compares to traditional design in plastic injection molding.

- 3D printing has enormous potential, but it’s not without distinct challenges. This Redshift piece examines the current limitations and problems with 3D printing and provides solutions.

Injection molding

Injection molding took off in the 1940s and 50s with the development of modern plastics, and today it’s used to create all sorts of products we use every day, from surgical devices to auto parts, water bottles to portable toilets. There has been steady, incremental innovation over the decades to improve it, and the innovation continues today thanks to simulation and new AI-based tools that provide insight for better quality and efficiency.

- Having trouble with air getting trapped in your molds during injection or cavities not getting filled completely? Learn how Moldflow simulation can help you predict and solve problems before they happen.

- David Clifton and Scott Hoover share a case study detailing how to use Fusion 360 to manage your molds.

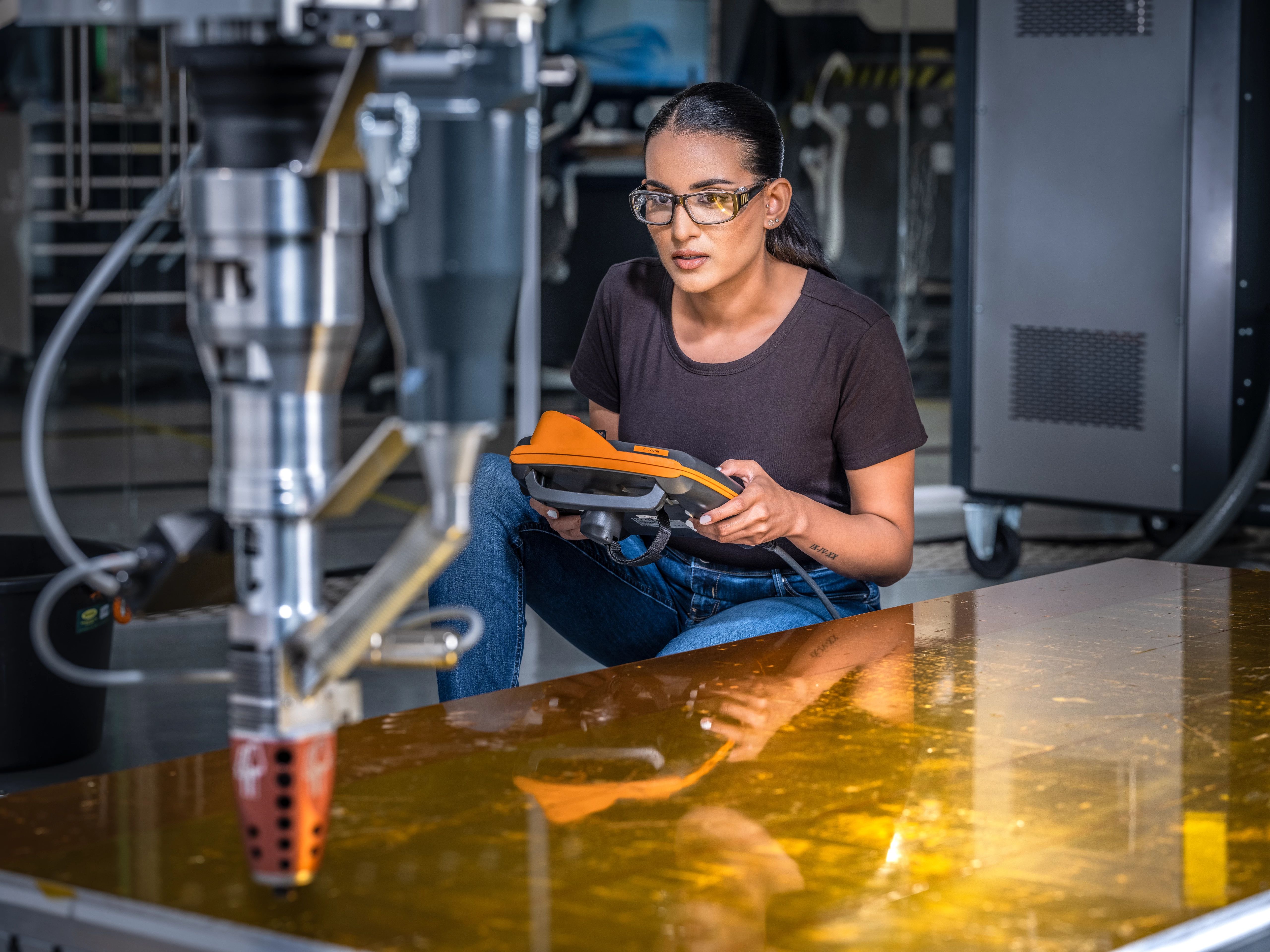

Robotics

Robots have come a long way since they came on the scene in the 1950s. Today you can find them in almost any shape and size, with different attachable grips and tools available for a range of tasks. What’s more, they’re easier than ever to program and train.

- This action-packed session shows you how to create a unique arm gripper for your own robot using Fusion 360 and generative design. You’ll learn the fundamentals of generative design in Fusion 360 while you’re at it.

- Danish company Odico is revolutionizing the wind energy industry with manufacturing robots. The company is also changing the way humans and robots work together. Instead of a human operating a large drilling unit on a turbine blade, robotic drilling and computer-aided manufacturing (CAM) are speeding things up and lowering risk at the same time.

What we mean by advanced manufacturing will continue to evolve. But whatever comes next, you can develop your industry insight and build your skills anytime at Autodesk University.