Amsterdam’s 3D-Printed MX3D Bridge and the Future of Smart Infrastructure

It’s hard to say what’s the most interesting aspect of the MX3D Bridge that was recently installed over an Amsterdam canal. For starters, it’s the world’s first 3D-printed steel bridge, created with a proprietary system that uses off-the-shelf robotic arms. It’s also a unique work of art and a useful piece of infrastructure.

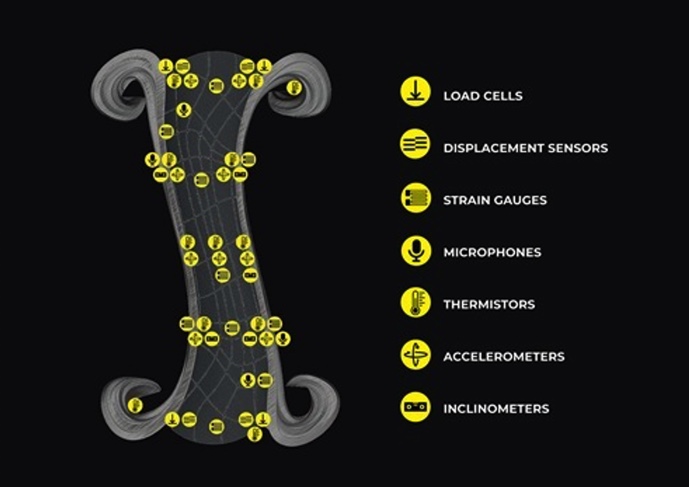

Perhaps even more important are the intelligent systems that are built into the bridge. Embedded sensors monitor the bridge’s environment, performance, and use. That data is processed in real time to create a digital twin of the bridge. As the first additively manufactured bridge of its kind, the team behind the project wants to learn how it responds to conditions over time.

The bridge was a multiyear collaboration between MX3D, a company specializing in large-scale additive manufacturing, and an international team of partners, including Autodesk, The Turing Institute, and the University of Twente. Designed by Joris Laarman Lab, the bridge shows what’s possible for smart infrastructure and smart cities.

Alex Tessier, a technical lead on the project, helped to develop and connect the systems and software for the bridge. “We see all infrastructure as elements for collecting data about the world around us to help us truly understand how things are used and how to make them better, safer, and more useful,” he said. “When you have many pieces of infrastructure that are smart, we can fuse all that data together and learn from it to help make better day-to-day decisions.”

Kean Walmsley, who works on Project Dasher, a 3D environment for data display, has blogged about the bridge extensively. “While I find the bridge beautiful and love the fact that it was 3D printed, I’m definitely most excited about the potential for using the bridge’s data to understand how to improve our cities’ infrastructure, whether by optimizing the functioning and usage of existing bridges or helping design future bridges with a more optimal use of resources,” Walmsley said.

Alec Shuldiner was project coordinator for the bridge project and chair of the Research Committee. An important focus for him was on the data ethics of smart infrastructure. “Principles governing data collection and use are not commonly agreed upon, nor does one size fit all,” Shuldiner said. “The bridge project is an example of how this question can be thoughtfully approached. It includes both a careful statement of how data will be collected, managed, and used, as well as processes for governing that.”

To get ready for the MX3D Bridge, the Autodesk team first created their own smart bridge in Autodesk’s Pier 9 workshop. Tessier led an AU class about it—The Making of an IoT Nervous System: Pier 9's Smart Bridge—that walks through the processes used to integrate IoT data into a BIM model with Forge, and to automate analysis of the data in real time. And check out Walmsley's article that explains how to build a digital twin that integrates real-world performance data using Forge.

Learn more about smart infrastructure anytime at Autodesk University.